Vision measurement system for wheel alignment parameters of multi-axle commercial vehicles based on two-dimensional targets

A technology for wheel positioning and visual measurement, which is applied in the field of measuring instruments to achieve the effects of wide applicability, large output and few machining processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

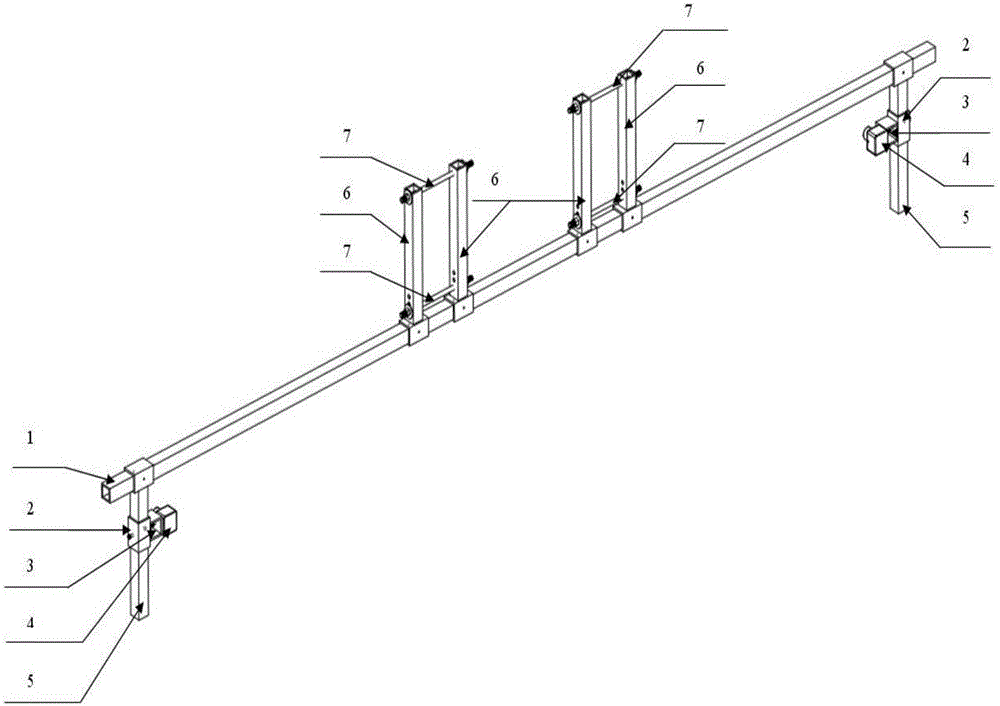

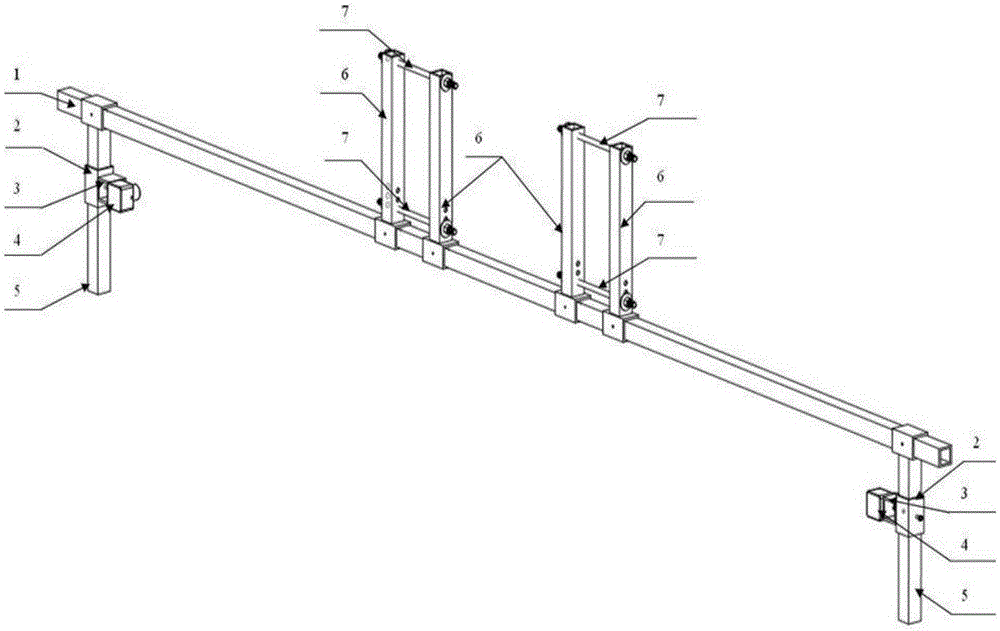

[0028] Below in conjunction with accompanying drawing, the present invention is described in further detail:

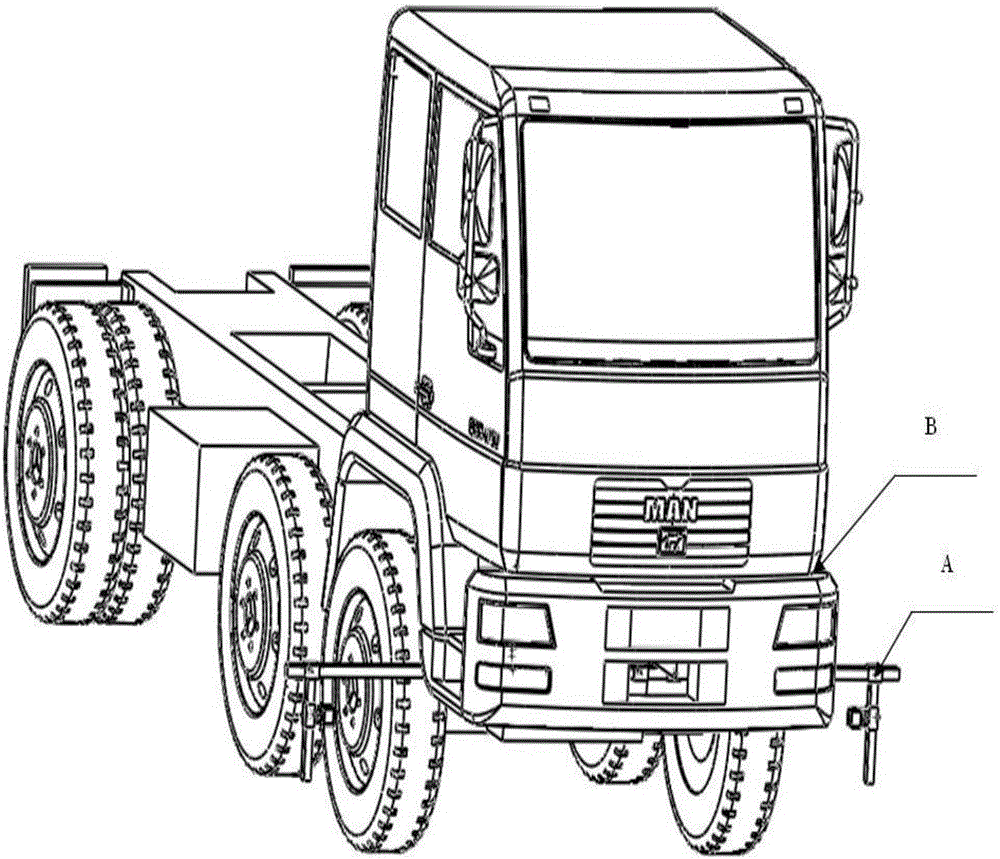

[0029] refer to Figure 1 to Figure 9 , the visual measurement system for multi-axis commercial vehicle wheel alignment parameters based on two-dimensional targets includes a beam 1 , a connecting block 2 , a camera base 3 , a camera 4 , a camera frame 5 , a splint 6 and a stud 7 .

[0030] The beam 1 is processed from a rectangular steel pipe.

[0031] The two connection blocks 2 are processed by rectangular steel pipes. Two threaded holes are symmetrically processed on both sides of the connection block 2. The bolts pass through the threaded holes on one side of the connection block 2. The ends of the bolts are connected to the long rectangular steel pipe surface of the camera frame 5 Contact tight fit.

[0032] The two camera bases 3 are processed from rectangular steel pipes, and two circular through holes are symmetrically processed on both sides of the camera b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com