Coiled tubing conveying resistance reducing device and using method

A technology of drag reduction device and tubing, which is applied in the direction of drill pipe, casing, earthwork drilling, etc. It can solve the problems of large downhole friction, difficult drilling pressure, difficulty in running in and out, etc., so as to prevent self-locking phenomenon, reduce The effect of small resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be described in further detail below in conjunction with the accompanying drawings.

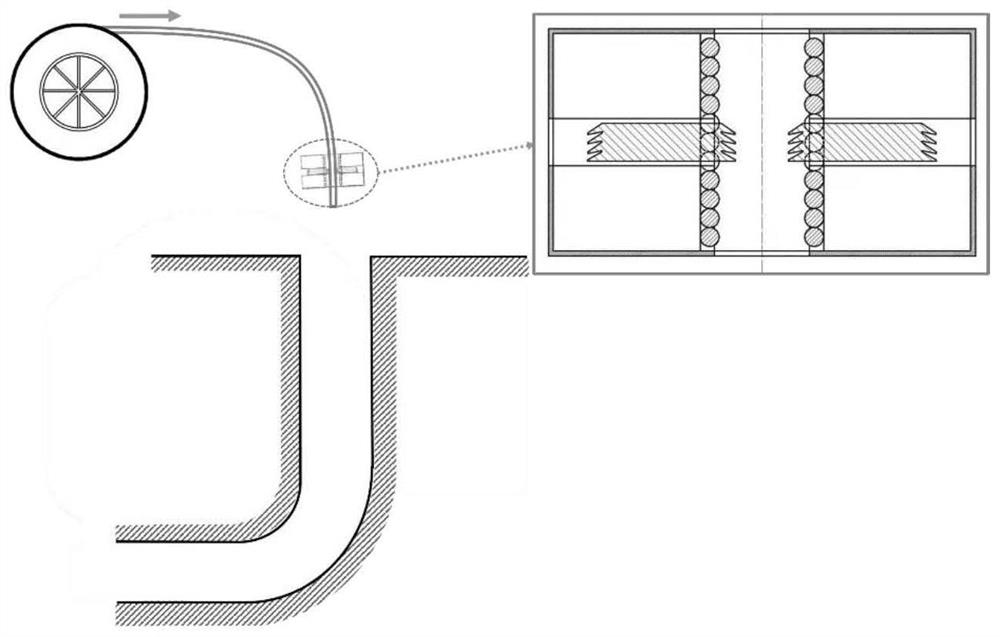

[0051] A drag reduction device for coiled tubing delivery, which is installed in the annular space between the coiled tubing and casing / open hole well wall. During installation, the coiled tubing is lowered into the well and anchored at the wellbore where buckling and self-locking are most likely to occur; in the working state of drag reduction, the coiled tubing can pass through the self-locking point more smoothly by using rolling friction, reducing buckling and self-locking possibility of occurrence. The device can work simultaneously at multiple different buckling self-locking points.

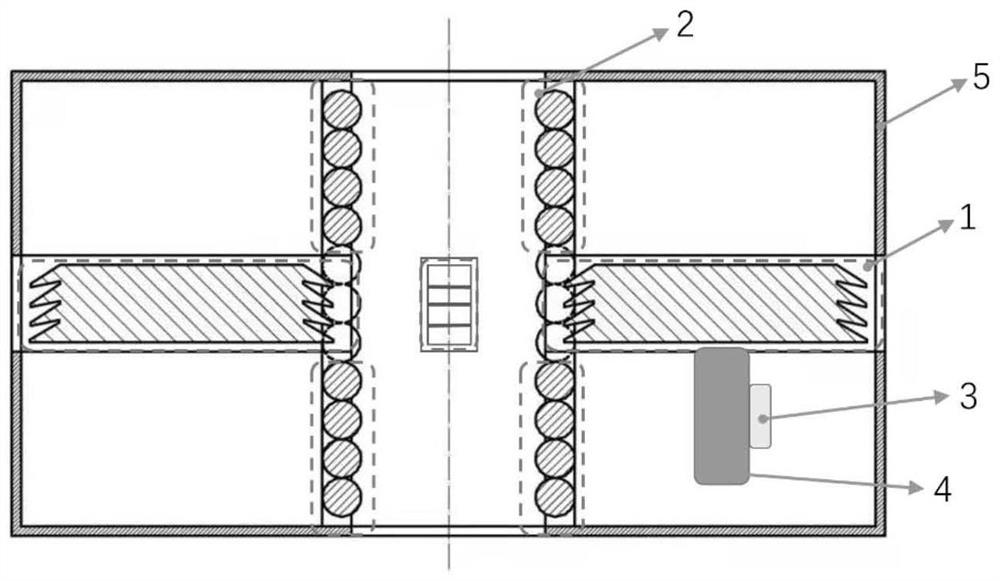

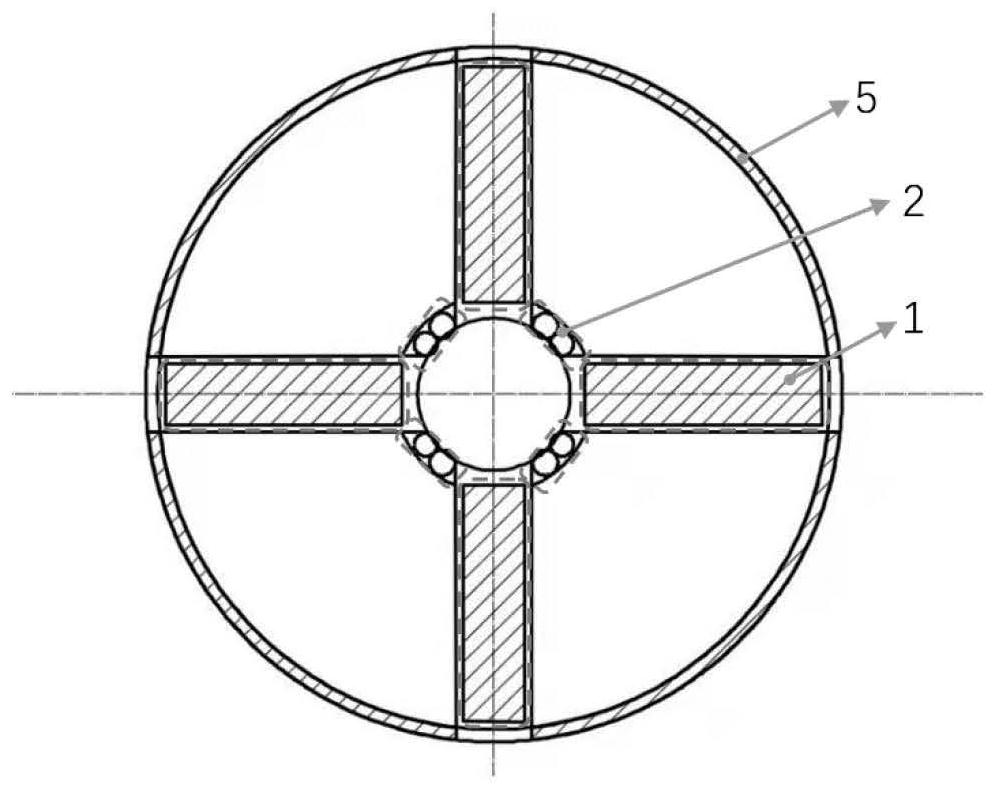

[0052] figure 1 It is a schematic diagram of the main functional modules contained in the present invention. Such as figure 1 As shown, the drag reduction device for coiled tubing transportation includes five functional modules: a limit mechanism 1 , a drag reduction m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com