Testing Device for Axial Clearance of Double Row Tapered Roller Bearing

A technology of tapered roller bearings and axial clearance, applied in the direction of mechanical clearance measurement, etc., can solve the problems of affecting detection efficiency, self-locking of rollers, and inability to accurately obtain measured values, so as to improve measurement accuracy and facilitate operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

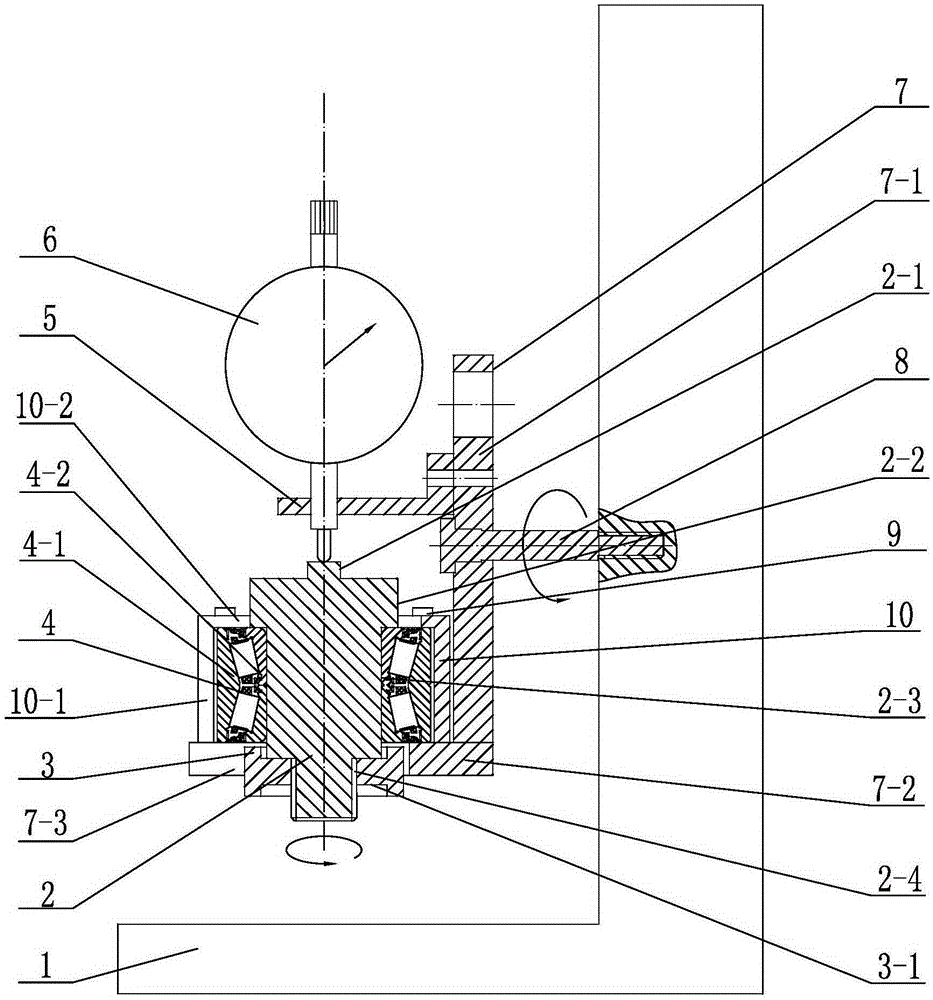

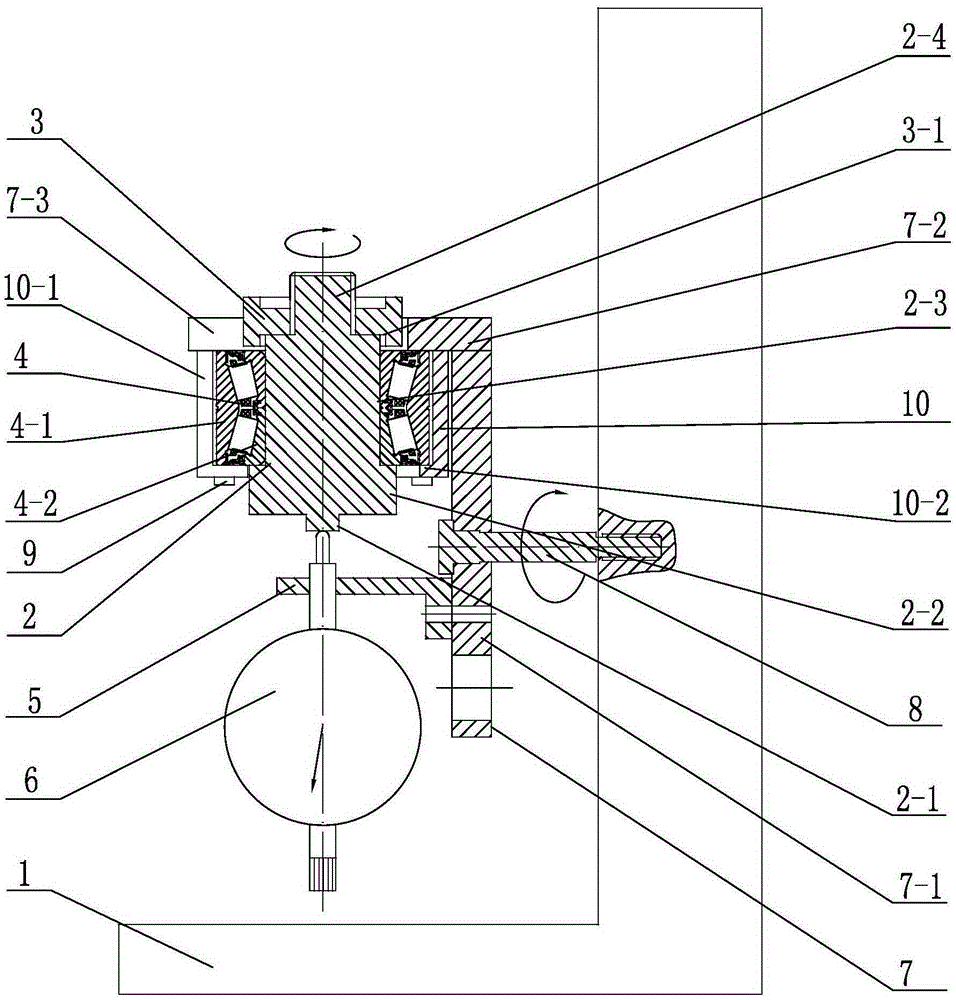

[0012] See figure 1 , 2 As shown, the detection device for the axial clearance of the double-row tapered roller bearing of the present invention includes a rotatable L-shaped support 7 installed on the watch base 1 and a measuring gauge 6. The L-shaped support 7 of the present invention includes a base plate 7- 2 and the vertical plate 7-1, the L-shaped support 7 can be integrated or assembled, the vertical plate 7-1 of the L-shaped support 7 is equipped with a supporting rotating part 8, and the supporting rotating part 8 is installed on the watch base 1 Above, the supporting rotating part 8 rotates with the table base 1 to drive the L-shaped support 7 to rotate 180°, or the L-shaped supporting part 7 rotates along the central axis of the supporting rotating part 8, so that the measured bearing 4 can be measured at different positions its axial clearance.

[0013] See figure 1 , 2 As shown, the base plate 7-2 of the present invention is provided with a U-shaped groove 7-3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com