Connection joint between elbow-type damper supports

A technology for connecting nodes and dampers, applied in protective buildings/shelters, building components, earthquake-proof, etc., can solve problems such as unfavorable support rotation, difficulty in processing and construction process, etc., to avoid stress concentration, reduce Bulky feeling, the effect of ensuring effective stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

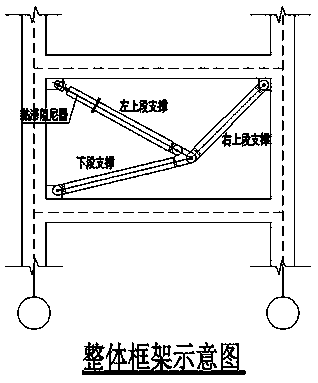

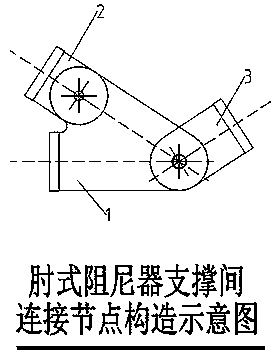

[0014] Such as Figure 2-5 The connecting node between the supports of the elbow damper shown includes the lower support special-shaped connection end 1 (consisting of a special-shaped plate, a circular plate and two pin shafts), the upper left support connection end 2 (consisting of two arched plate and a circular plate), the upper right support connecting end 3 (consisting of two plates and a circular plate), 1 and 2, 1 and 3 pass through pin shafts at holes 4 and 6, and holes 5 and 7 connect. When the lower special-shaped connection terminal 1 is connected to the left upper section connection terminal 2 and the right upper section connection terminal 3, the gap between the terminal plates should be controlled within 2 mm to prevent out-of-plane instability caused by the gap. After the installation is complete as Figure 6 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com