CNC small modulus straight bevel gear planer

A technology of straight bevel gear and gear planer, which is applied in the direction of gear tooth manufacturing device, gear cutting machine, belt/chain/gear, etc., which can solve the problem of inability to use small modulus straight bevel gear planer and insufficient movement of the knife Agile, reliable, and unable to meet the knife height adjustment range, etc., to achieve the effect of small space occupation, compact structure layout, and large knife height adjustment range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to further understand the content, features and effects of the present invention, the following embodiments are given as examples, and detailed descriptions are as follows with accompanying drawings:

[0035] It should be noted that, unless otherwise clearly specified and limited, the terms "first", "second", etc. do not represent sequential installation, nor the importance of the described components.

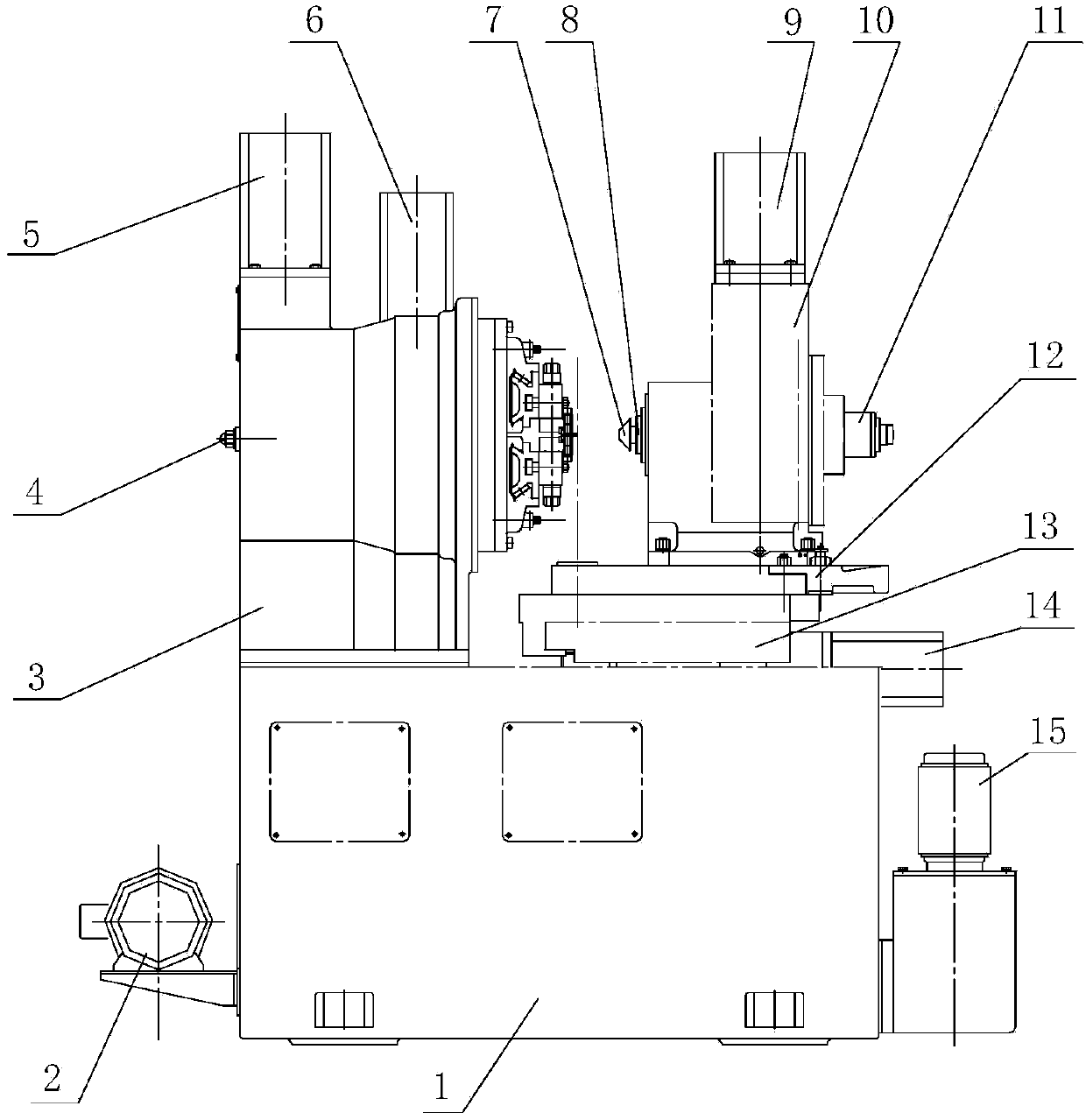

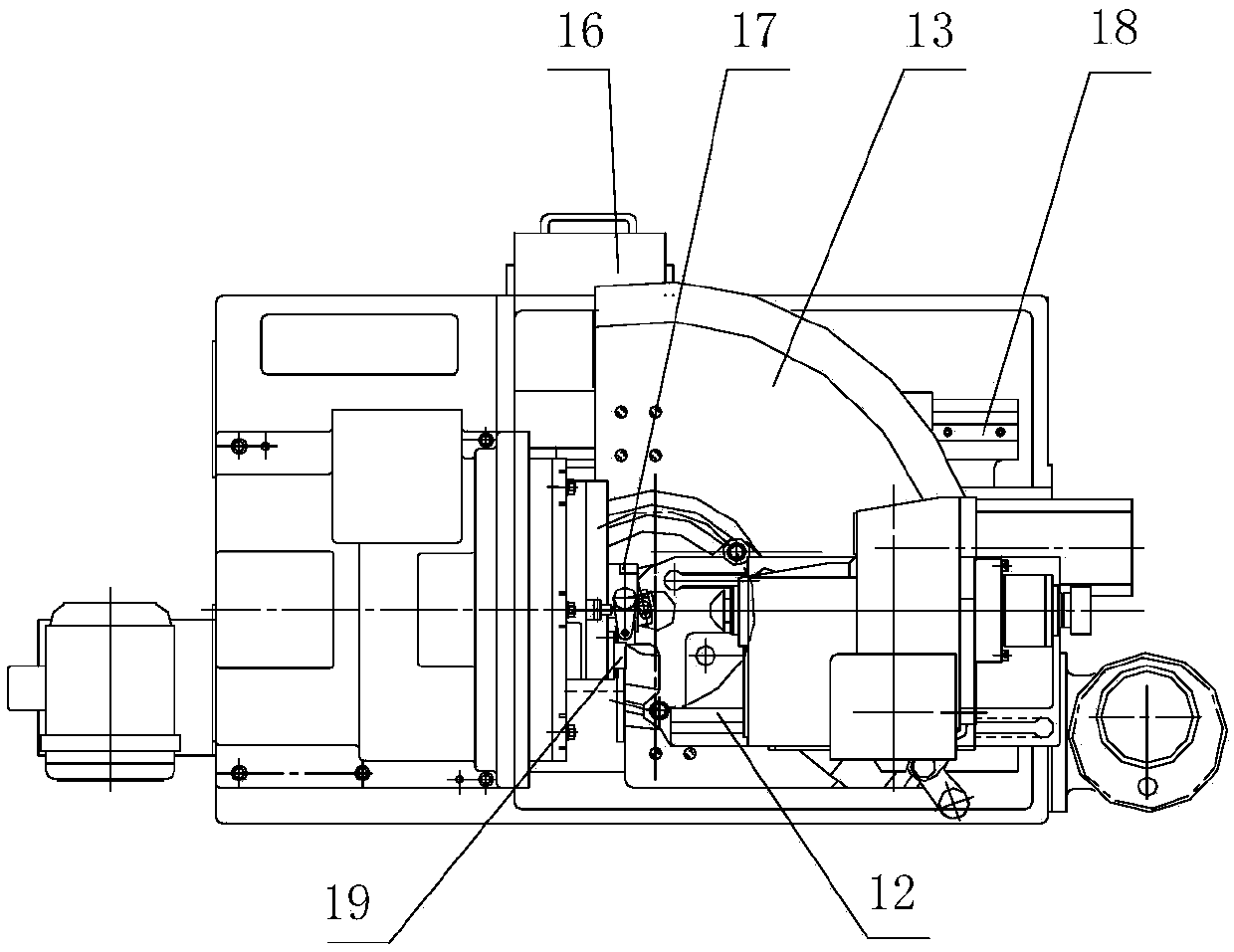

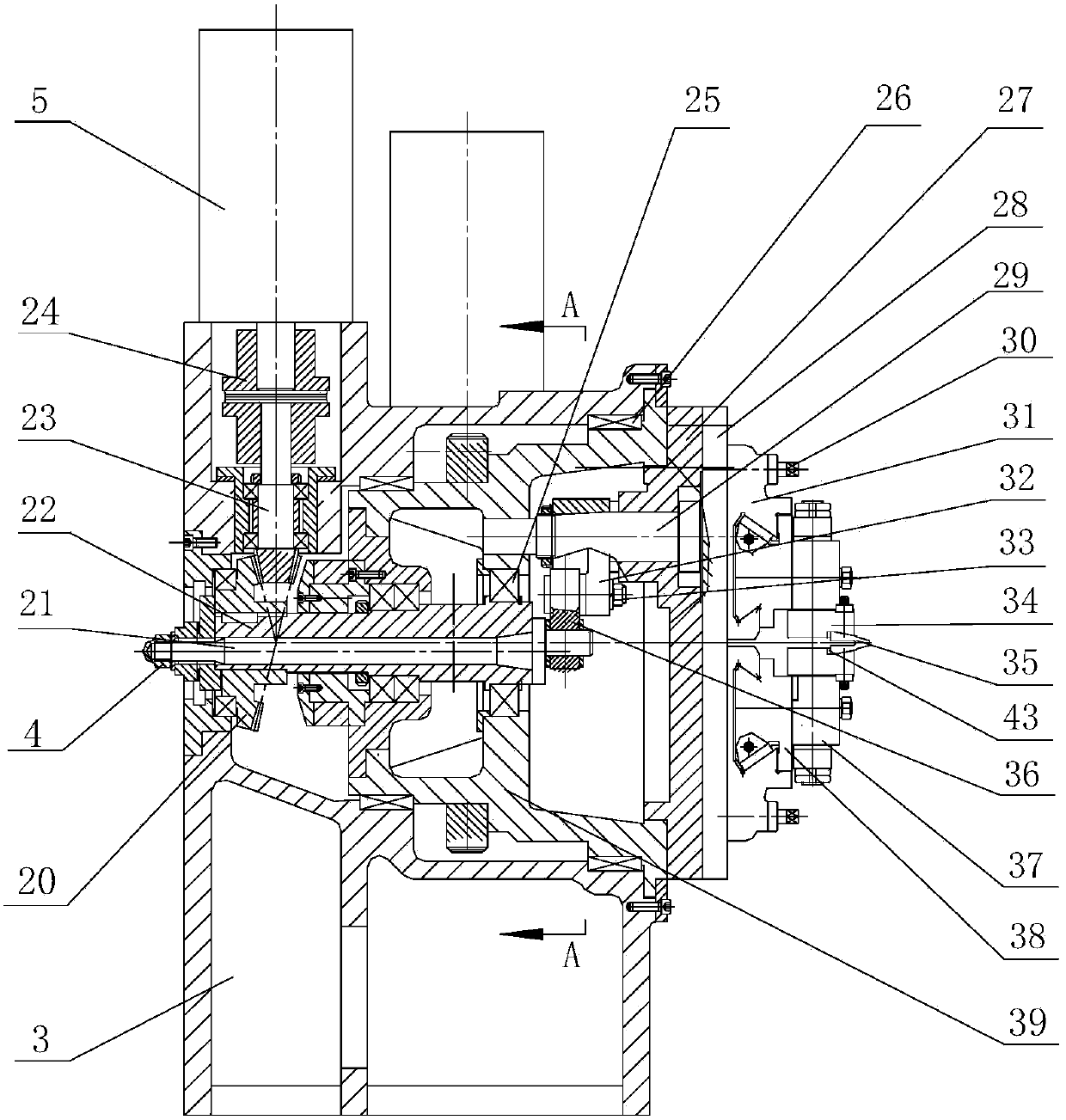

[0036] See figure 1 Figure 13 , CNC small module spur bevel gear planer, including bed 1, cradle assembly, workpiece box assembly, hydraulic system and CNC system, said hydraulic system including lubrication system 2 and cooling system 15, the bed The body is equipped with a rocking table assembly and a workpiece box assembly, and a lubrication system 2, a cooling system 15 and a numerical control system are provided on both sides of the bed. Two guide rails 18, a saddle moving servo motor 14 and a lead screw nut mechanism 42 are installed on the bed 1, and a saddl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com