Upright chain connecting ring used for mine chain and capable of preventing self-locking during chain piling

A technology for connecting chain rings and mines, applied in the direction of transmission chain, shackles, etc., can solve the problems of scrapping and loss of forgings and finished products, and achieve the effect of easy installation and large intermediate space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

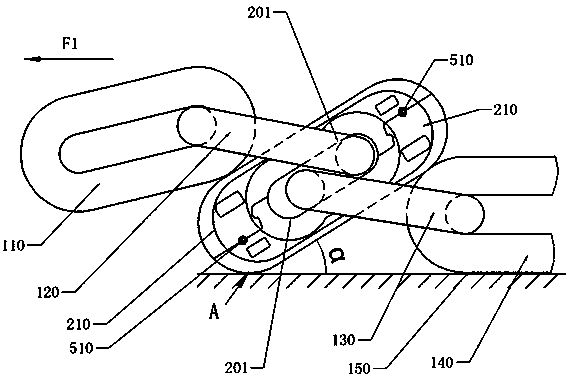

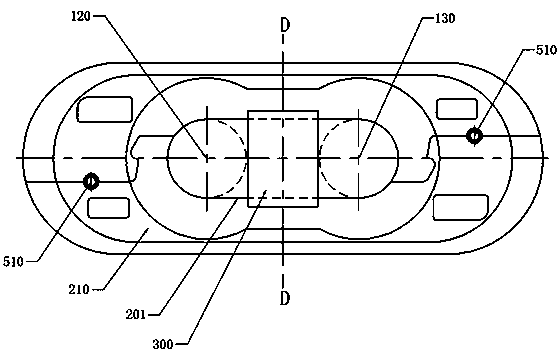

[0029] see Figure 2-Figure 6 , the vertical link link for mining chains in this embodiment includes two half-rings 210, and the two half-rings are assembled end to end, and an elastic pin 510 is inserted into the assembly place so as to realize the assembly of the two half-rings 210 into one A link link, the inner side of the link link is provided with a hollow link slot 201, and the link slot 201 is respectively buckled and assembled with the second link 120 and the third link 130 of the two chains that need to be connected, so as to realize Connection of two chains.

[0030] A block 300 is installed on the part between the second link 120 and the third link 130 in the link slot 201 , and the block 300 separates the second link 120 and the third link 130 open, thereby avoiding the occurrence of figure 1 self-locking phenomenon.

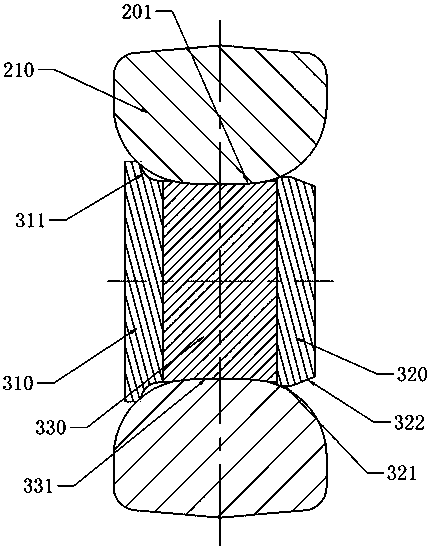

[0031] Preferably, the block 300 includes a first limiting portion 310, a second limiting portion 320, and a connecting portion 330, and the fir...

Embodiment 2

[0035] see Figure 7-Figure 9 , because in actual use, the way of block interference fit in the first embodiment is still prone to loosening and falling off, which leads to self-locking phenomenon after falling off. The applicant has found through research that the main reason for the shedding is that the stress point at the second limiting ring 321 is very small, and the second limiting ring 321 is squeezed and then opened after assembly. Once the second limiting ring 321 If the opening is not in place, the clamping performance will be seriously affected. Moreover, although the connection part 330 adopts an interference fit, once the second limiting ring 321 is not in place, it will easily slide and fall off when the clamping block is pushed by the axial direction. This axial thrust may be the component force of the friction force exerted on the block when the second link and the third link are in contact with the block during use, and once the block is knocked in, it needs ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com