Mechanical sliding sheet translation type precise seeding mechanism

A seeding device and a translational technology, which is applied in the direction of sowing, planter parts, hole planters, etc., can solve the problem of insufficient supply of seeds from the sorting box to the filling box, affect the reliability and stability of the equipment, and increase the installation accuracy Requirements and other issues, to achieve the effect of ingenious structural design, ensuring equipment reliability and stability, and reducing installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0027] Seed selection agency part:

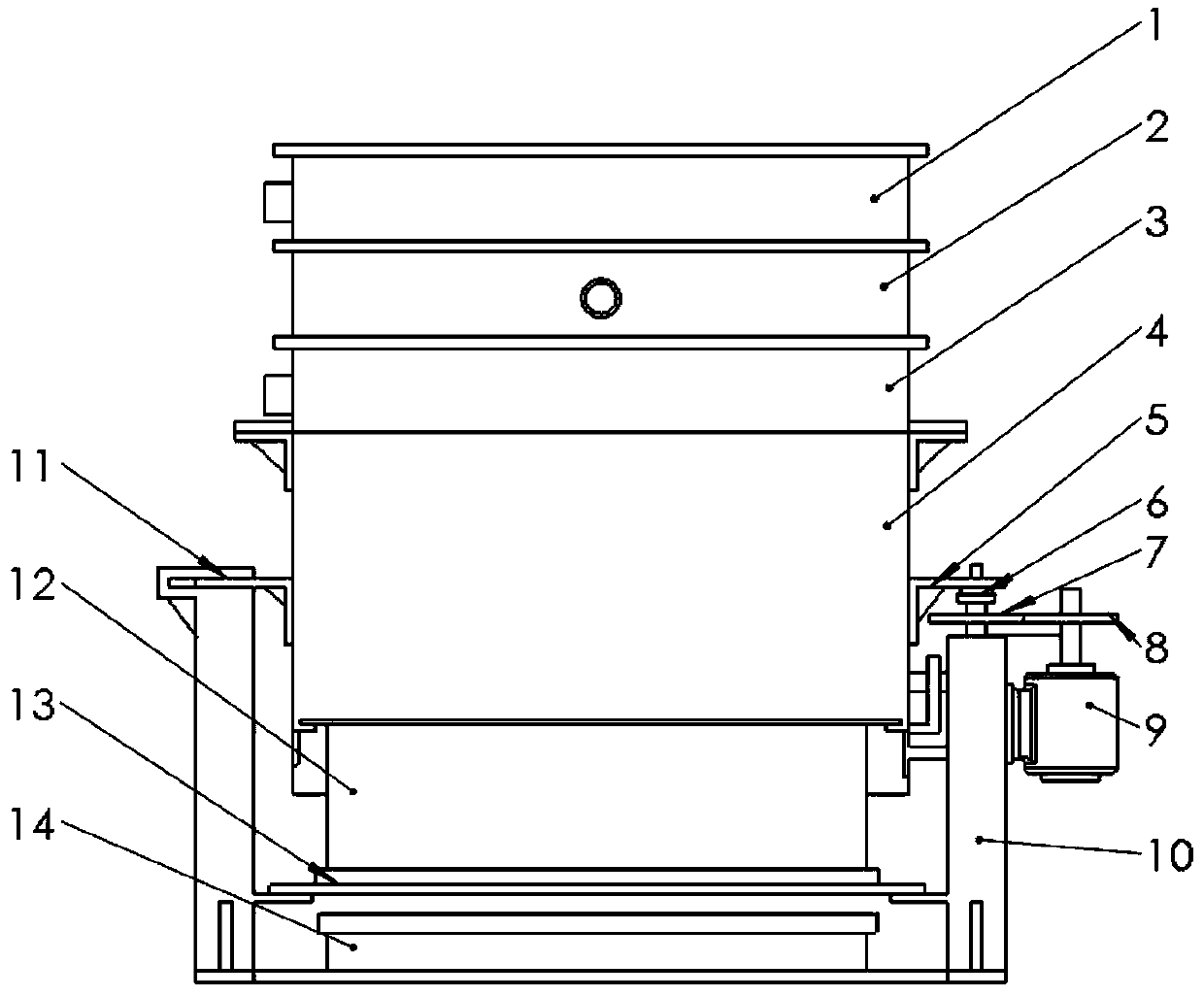

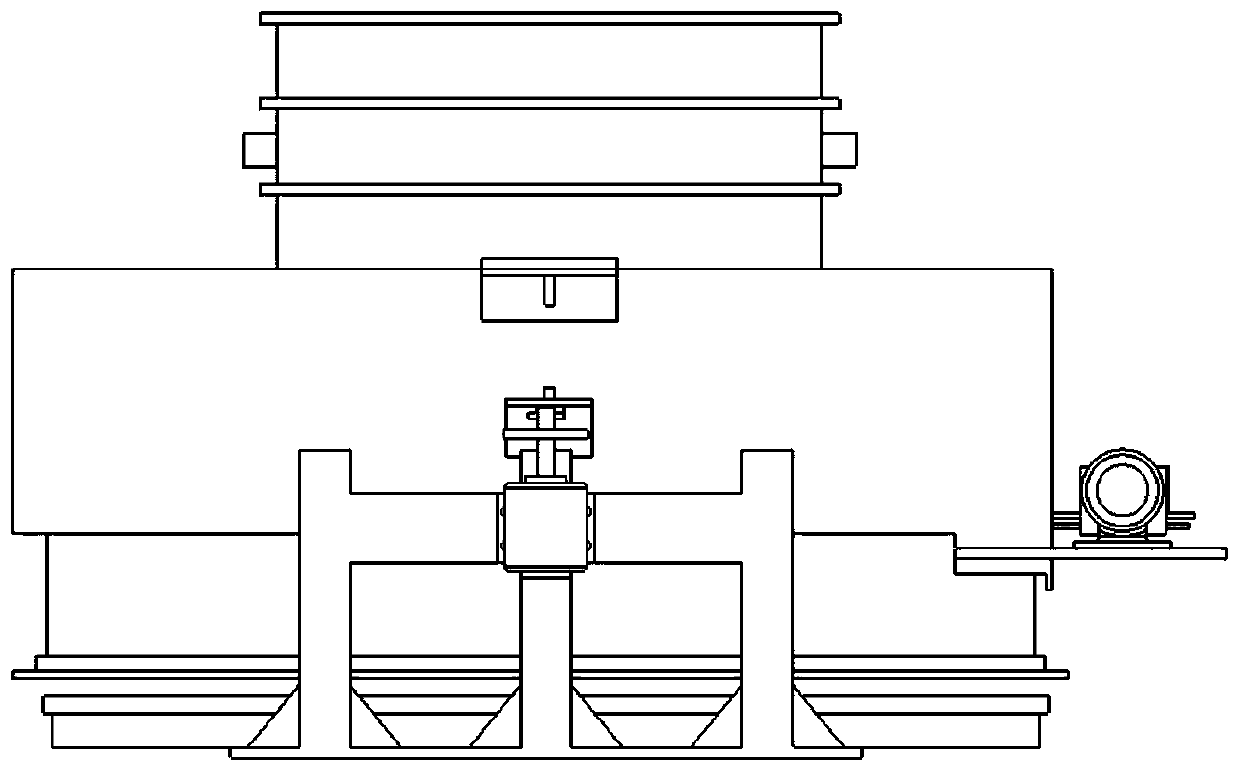

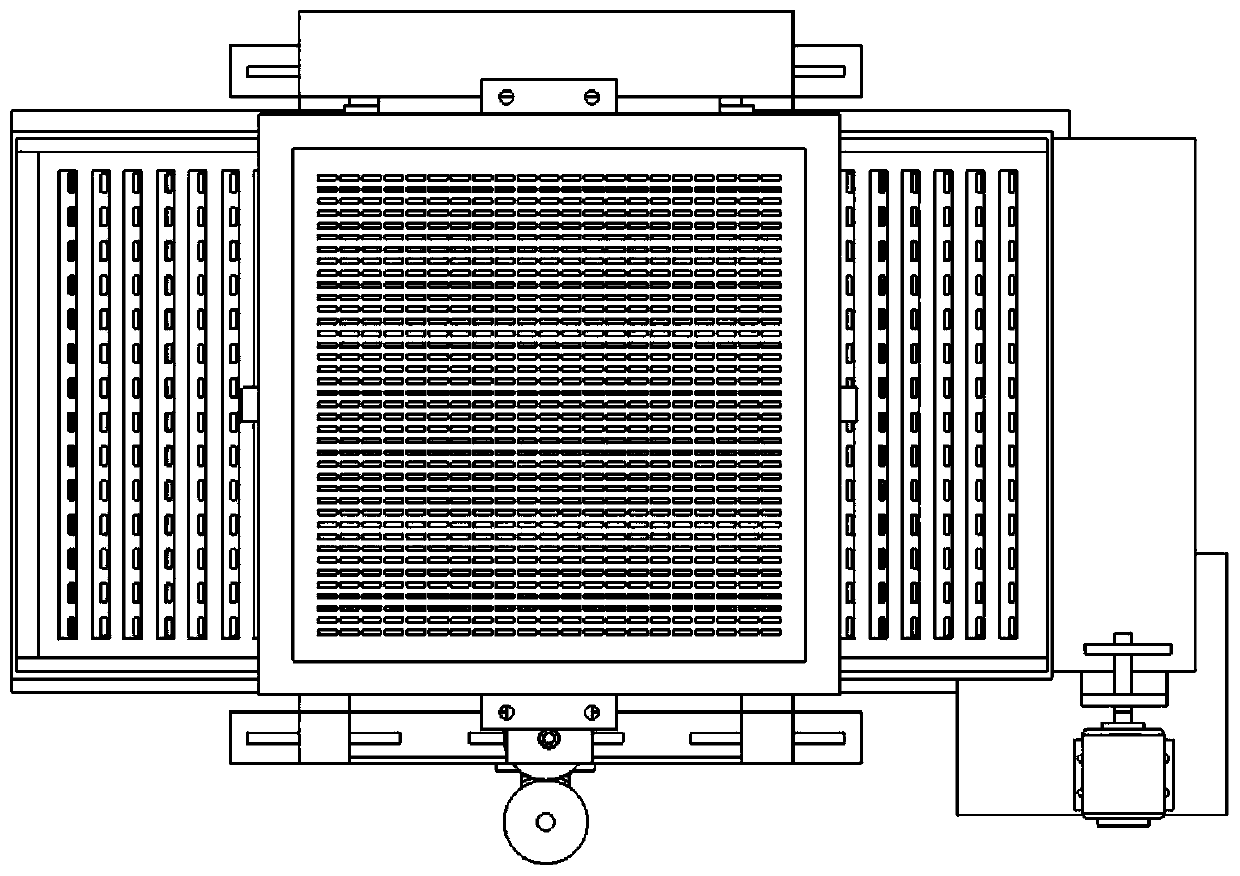

[0028] see Figure 1-5 , the third-level sorting box 3 is installed on the seed filling box 4; the second-level sorting box 3 is installed on the third-level sorting box 3; the first-level sorting box 1 is installed on the second-level sorting box 2;

[0029] Part of the filling mechanism:

[0030] The driving motor 9 is installed on the frame 10; the gear one 8 is installed on the driving motor 9, the gear two 7 is installed on the eccentric support 6, and is concentric with the main shaft of the eccentric support 6, and the gear one 8 and the gear two 7 form a gear pair for driving Motor 9 transmits power to eccentric support 6; Eccentric support 6 is installed on the frame 10; Then, between the main shaft of the eccentric support 6 and the frame 10, the rotating motion is completed through the frame be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com