High-friction-resistance ship arresting method

A ship and friction technology, applied in the direction of shipping equipment, climate change adaptation, etc., can solve the problems of ship out of control, arrest failure, operation error, etc., achieve low project cost and use cost, ensure effectiveness and reliability, and service life long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

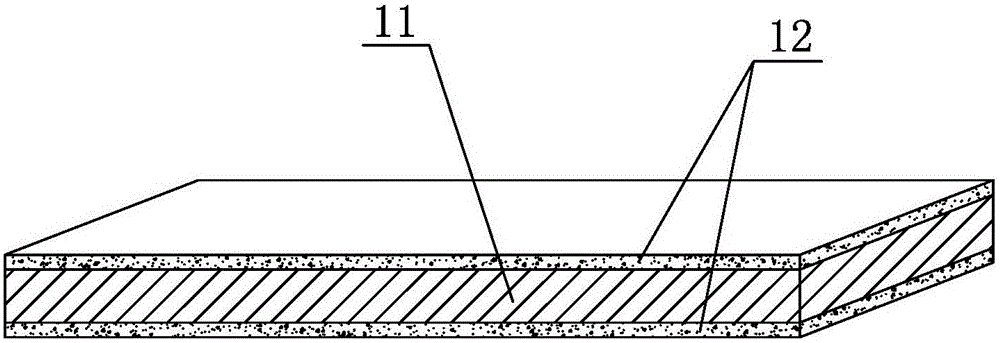

[0031] Embodiment 1: As shown in the figure, a high-friction ship arresting method includes the following specific steps:

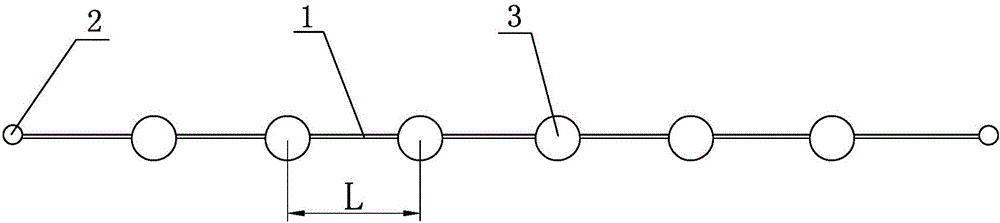

[0032] (1), the two ends of the high-friction interception cable 1 are fixedly connected to the force controller 2 respectively, and the connection form is: force controller 2—high friction interception cable 1—force controller 2, and the force controller 2 The ultimate tensile force of the high-friction interception cable 1 is less than the tensile strength of the high-friction interception cable 1, and the specific structure of the force controller 2 is:

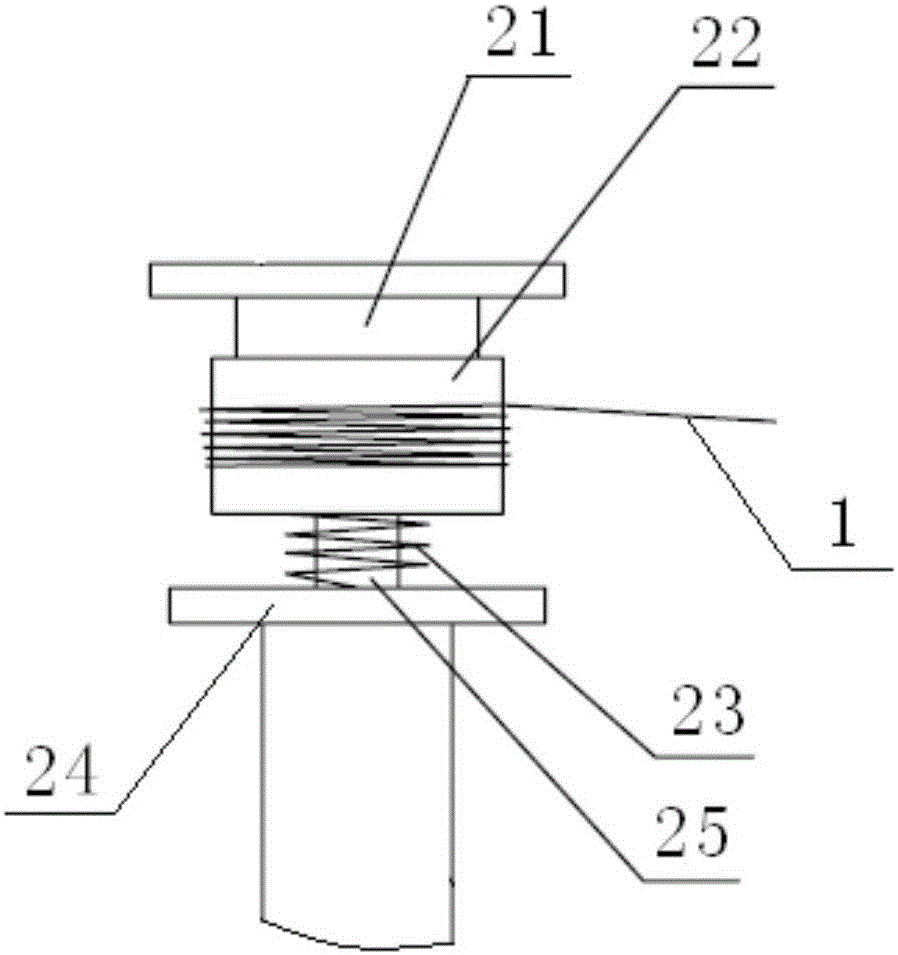

[0033] The force controller 2 comprises a friction block 21, a friction roller 22, a strong spring 23 and a fixed support platform 24, the support platform 24 is fixedly provided with a central shaft 25, the friction block 21 is fixedly arranged on the central shaft 25, and the friction roller 22 and the powerful spring 23 are both sleeved on the central shaft 25, and the powerful spring 23 is connect...

Embodiment 2

[0038] Embodiment 2: As shown in the figure, a high-friction ship arresting method includes the following specific steps:

[0039] (1), the two ends of the high-friction interception cable 1 are fixedly connected to the force controller 2 respectively, and the connection form is: force controller 2—high friction interception cable 1—force controller 2, and the force controller 2 The ultimate tensile force of the high-friction interception cable 1 is less than the tensile strength of the high-friction interception cable 1, and the specific structure of the force controller 2 is:

[0040] The force controller 2 includes a fixed connection platform 26, after the high friction interception cable 1 is bent, it is fixedly connected with a plurality of parallel connection cables 27, and the end of the high friction interception cable 1 is fixedly connected with the connection platform 26;

[0041] (2), fixing a plurality of buoys 3 equally spaced on the high-friction interception cab...

Embodiment 3

[0045] Embodiment 3: As shown in the figure, a high-friction ship arresting method includes the following specific steps:

[0046] (1), the two ends of the high-friction interception cable 1 are fixedly connected to the force controller 2 respectively, and the connection form is: force controller 2—high friction interception cable 1—force controller 2, and the force controller 2 The ultimate tensile force of the high-friction interception cable 1 is less than the tensile strength of the high-friction interception cable 1, and the specific structure of the force controller 2 is:

[0047] The force controller 2 includes a fixed connection platform 26, and the high-friction interception cable 1 is bonded and fixed on the connection platform 26 in a curved shape through an epoxy resin adhesive 28 or other high-strength adhesive;

[0048] (2), fixing a plurality of buoys 3 equally spaced on the high-friction interception cable 1, so that the high-friction interception cable 1 float...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com