Adjusting tool for machining lathe claw

A lathe and tooling technology, used in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., to achieve the effect of improving dimensional accuracy, improving sliding smoothness, and precise tool feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

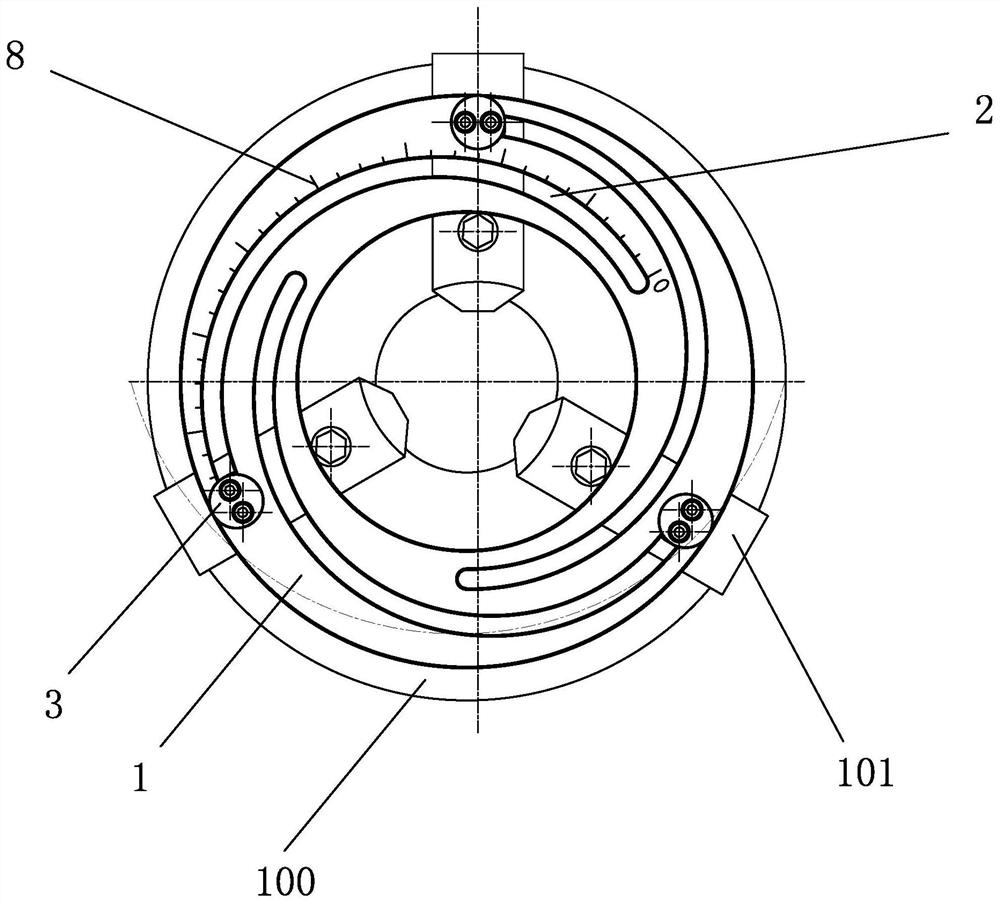

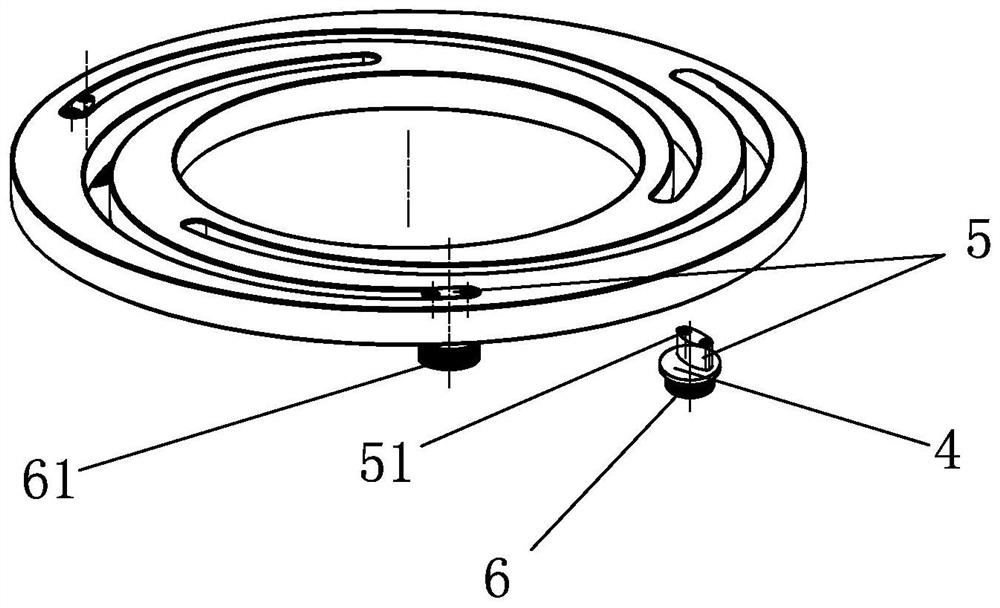

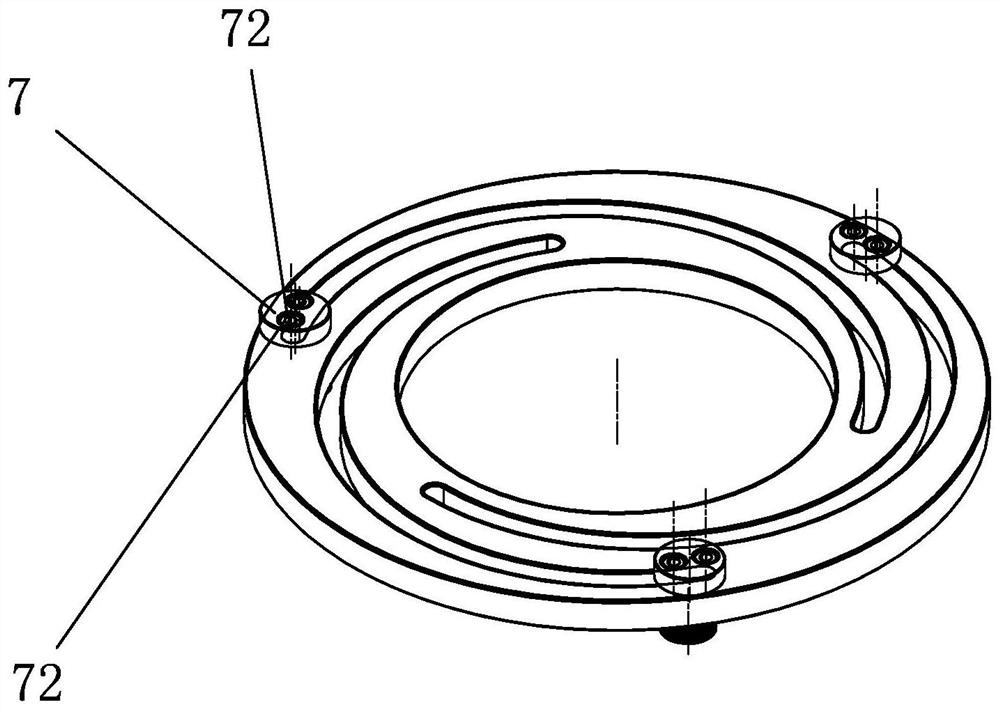

[0028] like figure 1 , 2 As shown in the figure, an adjusting tool for processing lathe jaws includes an adjustable base plate 1 arranged on the main shaft 100 of the equipment. The adjustable base plate 1 is provided with a chute group, and the chute group includes at least two radians. Gradient chute 2, the chute 2 of the chute group is arranged symmetrically along the center of the adjustable base plate 1; wherein, each chute 2 is slidably provided with a tooling slider 3, and the bottom of the tooling slider 3 can be slidably arranged. Connect the jaws 101 of the lathe to be processed. The chute 2 is arranged in an involute with the center of the adjustable base plate 1 as the center. The equipment main shaft 100 is provided with a guide rail, and the claw 101 of the lathe to be processed moves in the guide rail along the radial direction of the equipment main shaft 100 .

[0029]The radian of the chute 2 of the chute group is gradual. When the operator rotates the adju...

Embodiment 2

[0035] like Figure 5 As shown, the difference from Embodiment 1 is that in this embodiment, the main shaft 100 of the equipment is of a horizontal structure, the adjustable base plate 1 is arranged on the side of the main shaft 100 of the equipment, and the claw 101 of the lathe to be processed is under the limit of the tooling slider 3 The radial direction deviation will not be generated due to gravity, and the radial distance is always accurately adjusted with the rotation angle of the adjustable base plate 1. It can be seen from this embodiment that the tooling provided by the present invention is used in the vertical spindle and the horizontal spindle. can be used normally.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com