Support method for underground goaf roof of coal mine

A technology for gobs and coal mines, applied in mining equipment, earthwork drilling, bolt installation, etc., can solve problems such as roof falling, process interference, ground subsidence, etc., to reduce coal mining costs, save coal resources, The effect of subsidence deformation is small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

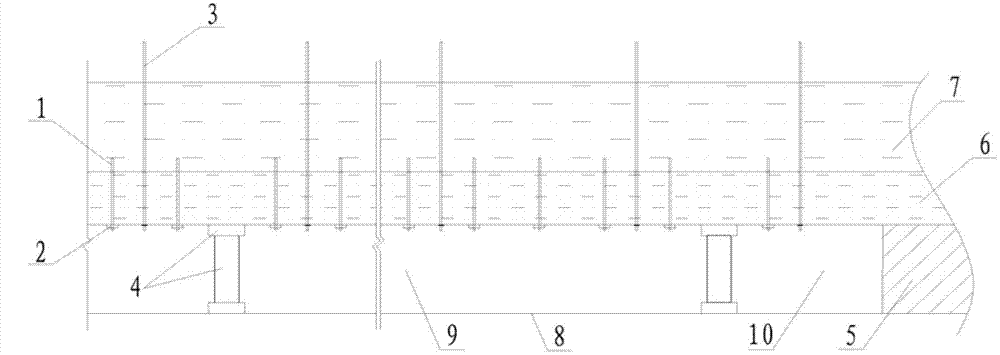

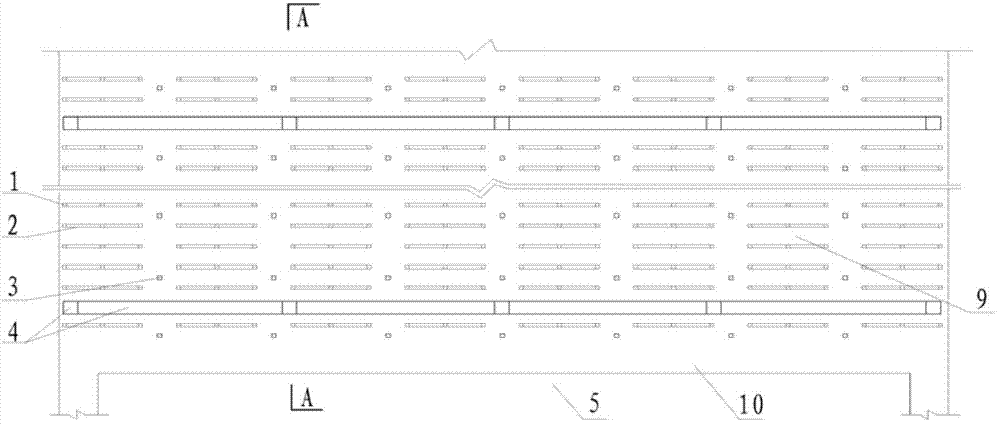

[0030] The goaf roof support method of this embodiment, such as figure 1 , 2 shown, including the following steps:

[0031] 1) It is measured that the direct roof 6 of the underground working face of the coal mine is shale and siltstone, with a thickness of 2.4m, and the initial caving step is 3m; the old roof 7 is medium and siltstone, with a thickness of 8.5m, and the initial fracture step is 30m;

[0032] 2) As the coal mining face 10 advances, select threaded steel anchor rods 1 with a diameter of 22 mm and a length of 3000 mm and steel joists 2 with a diameter of 22 mm × 2600 mm, and use a bolter drilling rig to drill directly into the goaf according to the row spacing of 800 mm × 800 mm. The top 6 board is supported by anchor rod 1 and steel joist 2, and the anchor rod 1 and steel joist 2 are close to the top 6 directly; choose the anchor cable 3 with a diameter of 34mm and a length of 8300mm, and use anchor cables according to the row spacing of 2400mm×2400mm The dril...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com