Concrete foundation-free highway culvert for permafrost region

A technology for permafrost areas and foundations, applied to the ground floor of roads, buildings, etc., can solve the problems of strong resistance to deformation and low construction cost, and achieve the effects of strong resistance to deformation, low construction cost and simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to further describe the present invention, the present invention will be further described below in conjunction with the embodiments and accompanying drawings.

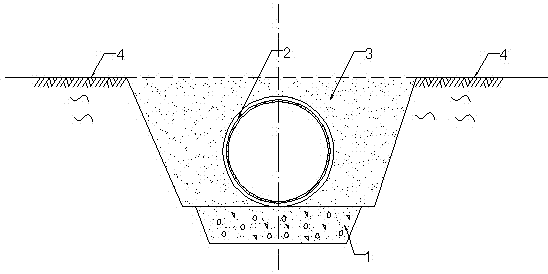

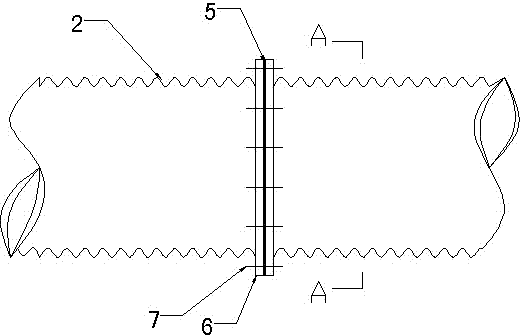

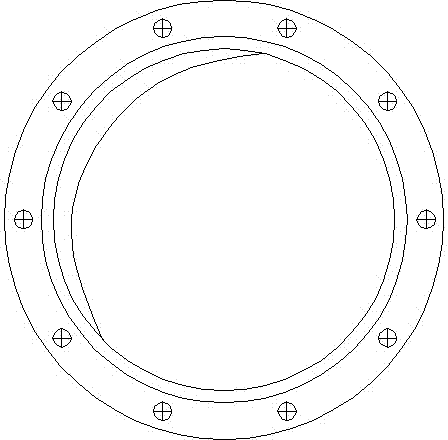

[0013] As shown in the figure, the construction steps of a culvert without concrete foundation for highways in permafrost regions are as follows: 1. Excavation of the foundation pit: According to the actual geological conditions of the original ground 4 and the design depth of the drawings, use an excavator to excavate to a distance from the base After about 10~20cm, use manual excavation, and level it after reaching the designed base. Immediately after the excavation is completed, the bearing capacity of the foundation is tested, and the general requirement is not less than 150Kpa. 2. Filling with gravel: After the excavation of the foundation pit is completed, fill the graded gravel 1, the thickness of the gravel foundation is not less than 0.5~1.0m, the bottom width is greater than the diameter of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com