Insert molding product

A technology for molded products and resin molding, which is applied to the components of pumping devices for elastic fluids, non-variable displacement pumps, driving pumps, etc., and can solve the use limitations of insert molded products, the complexity of resin molded products, and the increase in manufacturing costs. big problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

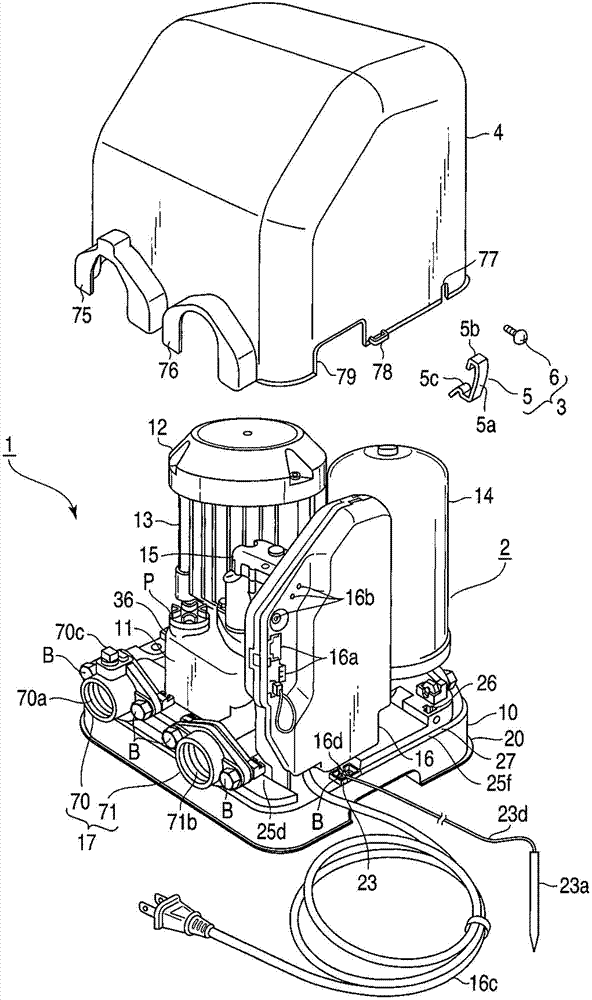

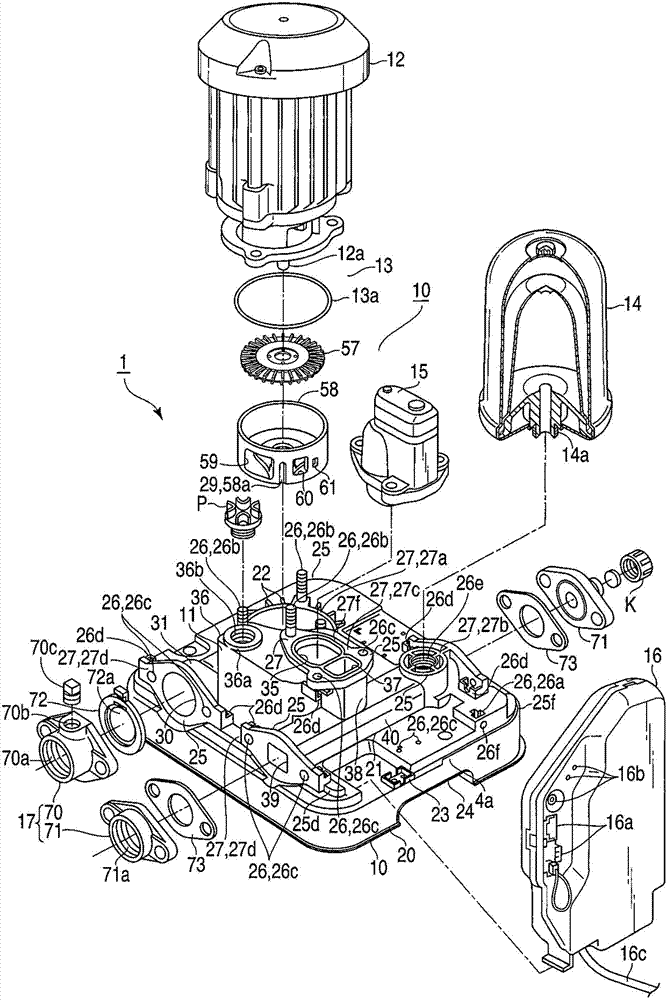

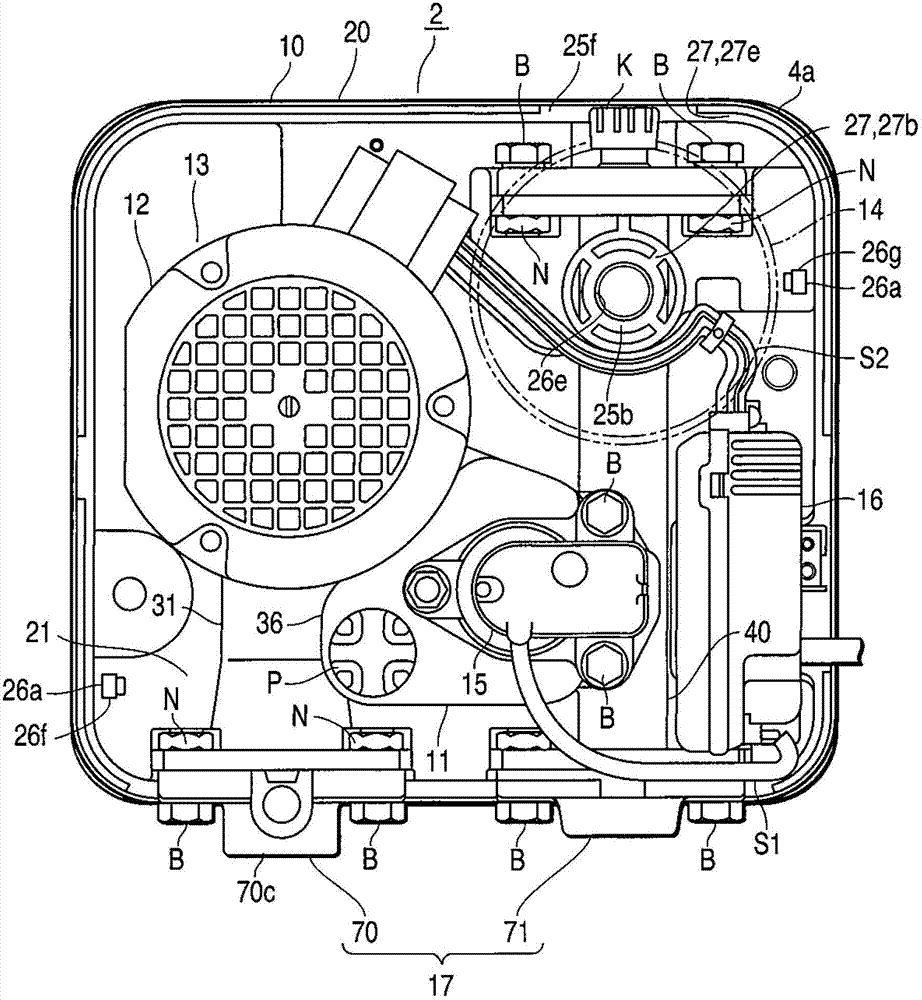

[0040] figure 1 It is a perspective view which shows the structure of the water supply apparatus 1 which concerns on one Embodiment of this invention. figure 2 It is an exploded perspective view showing the configuration of the main body 2 of the same water supply device 1 . image 3 It is a top view showing the structure of the main body part 2 . Figure 4 It is a bottom view showing the structure of the main body part 2 . Figure 5 It is a perspective view which shows the structure of the base part 10 used for the main body part 2. As shown in FIG. Figure 6 It is a plan view showing the structure of the base part 10 . Figure 7 It is a bottom view showing the structure of the base portion 10 . Figure 8It is a cross-sectional view showing the flow path portion 21 of the base portion 10 . In addition, in Figure 1-8 Among them, B represents the bolt, F and F1 represent the flow of water, K represents the cap, P represents the piston, S represents the screw, S1 and S2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com