Cutter friction abrasion testing machine for simulating shield construction conditions, testing cutter and testing method

A friction and wear test, tool technology, applied in the direction of testing wear resistance, measuring devices, instruments, etc., can solve the problems of large size, large test device, high cost, etc., to reduce the test tool, reduce the test cost, and reduce the size of the sample small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1: Simulate the tool wear conditions during the construction of a full-face hard rock tunneling machine, and study the wear failure behavior of the hob cutter ring.

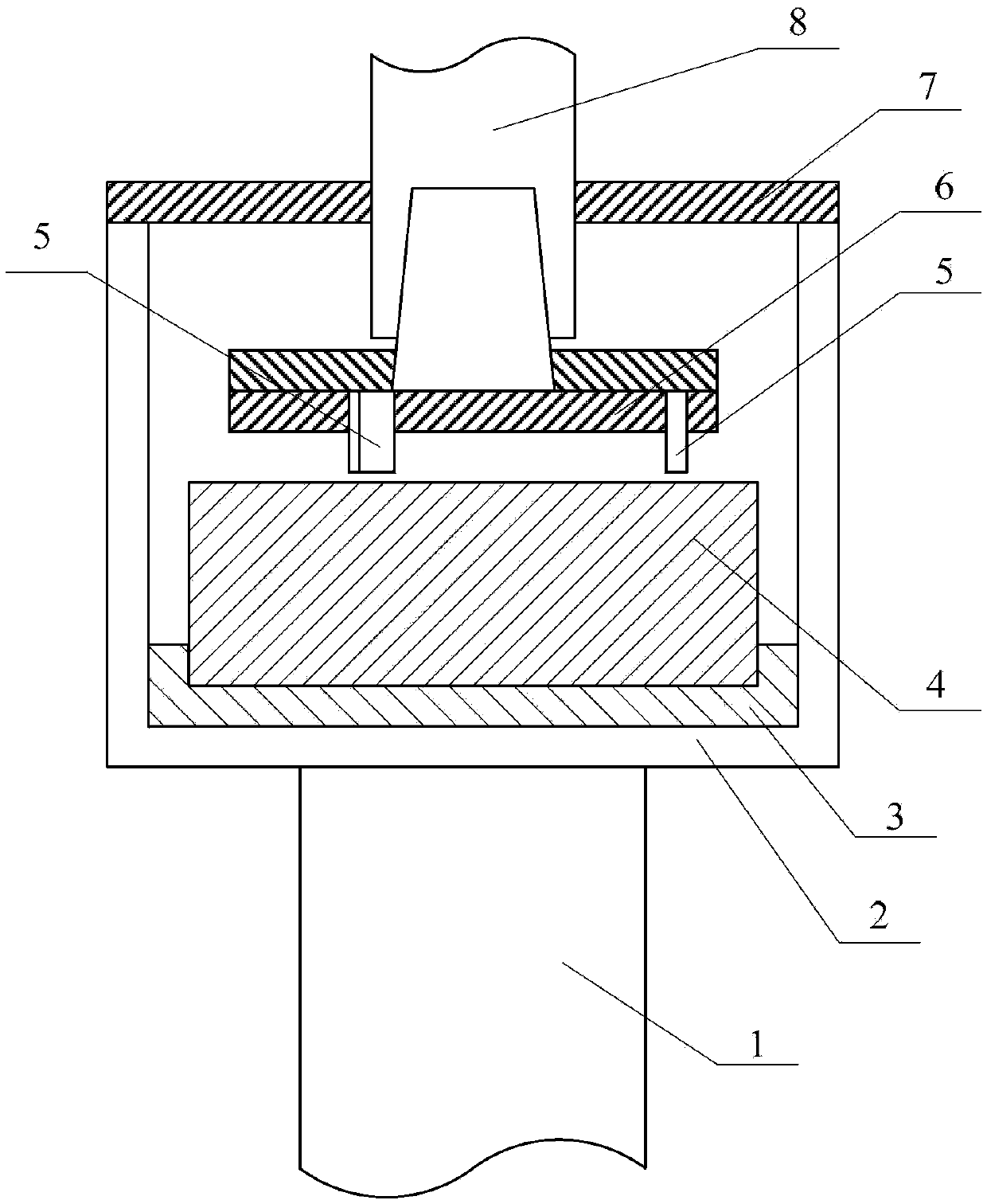

[0033] Referring to the accompanying drawings, the tool friction and wear test device for simulating shield construction conditions includes hydraulic jacking cylinder 1, mud box 2, lower sample fixture 3, lower sample 4, test tool 5, upper sample fixture 6, mud Box cover plate 7, rotating shaft 8.

[0034] The test tool 5 is a shield hob cutter ring, which is processed into a 3mm×5mm×15mm cuboid by wire cutting, and a 3mm×5mm end face is ground for grinding against the sample under the rock. The size of the positioning hole of the corresponding upper sample fixture is 3mm×5mm. The lower sample is granite with a size of 80mm×80mm×30mm.

[0035] When the tool friction and wear testing machine simulating the construction conditions of shield tunneling is working, the test tool 5 is fixed on the upp...

Embodiment 2

[0036] Example 2: Simulate the tool wear condition during construction of the hybrid shield machine, and study the wear failure behavior of the hob cutter ring.

[0037]The test tool 5 is a shield hob cutter ring, which is processed into a 3mm×5mm×15mm cuboid by wire cutting, and a 3mm×5mm end face is ground for grinding against the sample under the rock. The size of the positioning hole of the corresponding upper sample fixture is 3mm×5mm. The lower sample is sandstone with a size of 80mm×80mm×30mm. The mud composition includes: 15% water, 50% fine sand (diameter less than 3mm) and 20% soil.

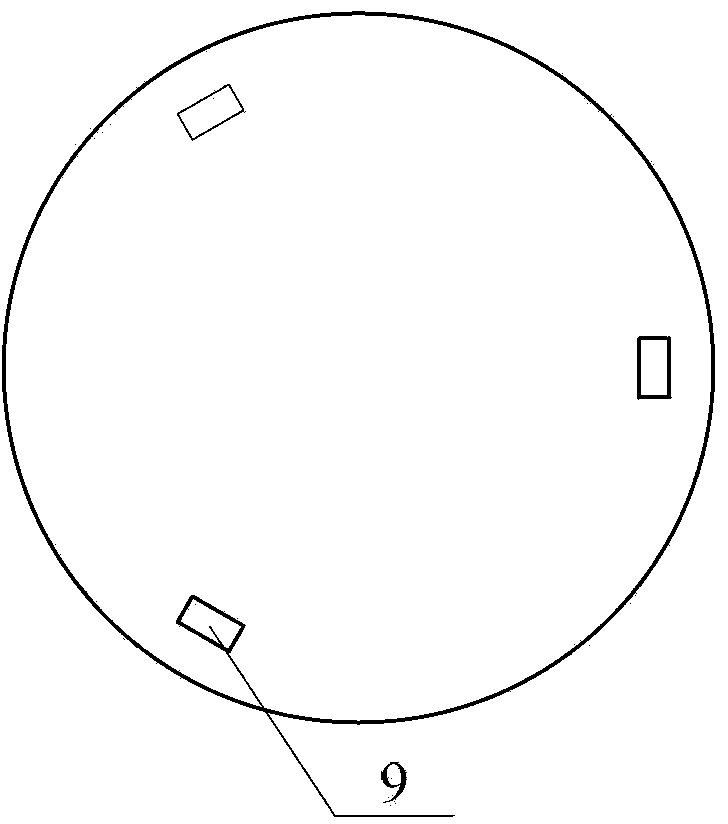

[0038] When the tool friction and wear testing machine simulating the construction conditions of shield tunneling is working, the test tool 5 is fixed on the upper sample holder 6 through the test tool positioning hole 9 and the lateral screw, and the lower sample 4 is fixed on the lower sample holder 3 and juxtaposed In the mud box 3, add the above mud to the mud box 3, fix the mud b...

Embodiment 3

[0039] Example 3: Simulate the tool wear condition during construction of the hybrid shield machine, and study the wear failure behavior of the cutting tool.

[0040] The test tool is a cemented carbide rack used on the cutter, which is processed into a 3mm×5mm×15mm cuboid by wire cutting, and a 3mm×5mm end face is ground for grinding against the sample under the rock. The size of the positioning hole of the corresponding upper sample fixture is 3mm×5mm. The lower sample is sandstone with a size of 80mm×80mm×30mm. The mud composition includes: 15% water, 50% fine sand (diameter less than 3mm) and 20% soil.

[0041] When the tool friction and wear testing machine simulating the construction conditions of shield tunneling is working, the test tool 5 is fixed on the upper sample holder 6 through the test tool positioning hole 9 and the lateral screw, and the lower sample 4 is fixed on the lower sample holder 3 and juxtaposed In the mud box 3, add the above mud to the mud box 3,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com