Flicker swinging and trimming line practical training operation system and implementation method thereof

An operating system and thread trimming technology, applied to instruments, simulators, aerospace equipment, etc., can solve the problems of limited employee proficiency, long training time, difficult use and operation, etc., to shorten the operation training time and improve operation training effect, the effect of improving professional skills

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

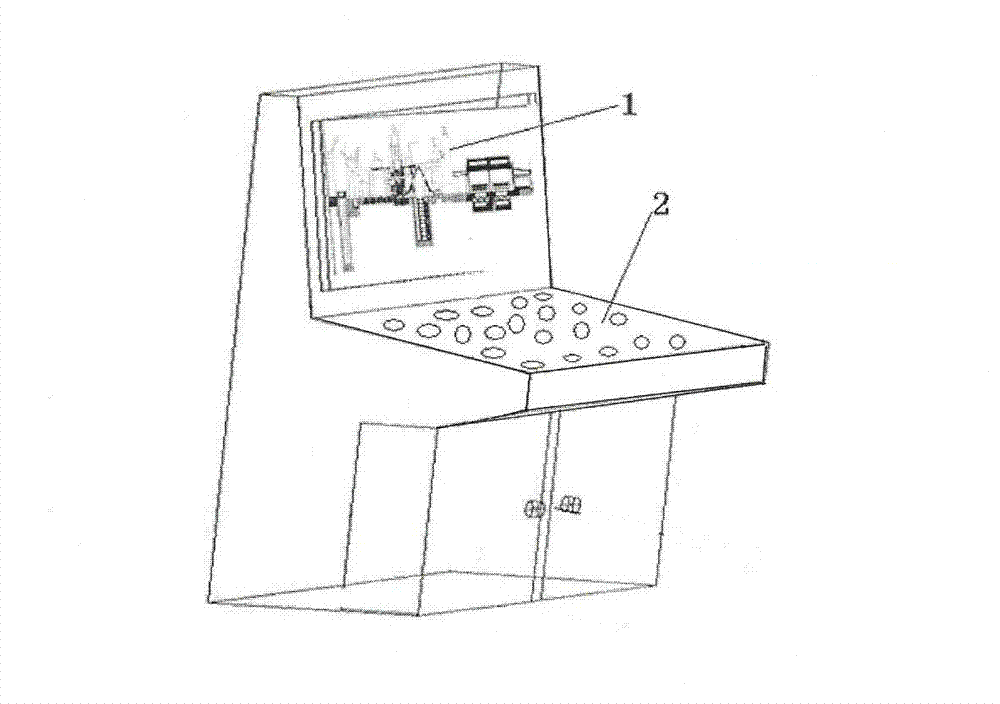

[0025] see figure 1 and figure 2 As shown, the flickering pendulum line trimming training operating system of the present invention includes:

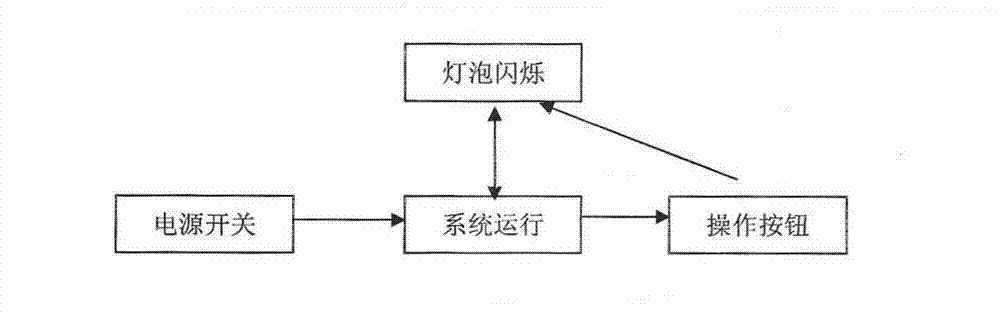

[0026] The power switch is the switch to control the flickering pendulum line trimming training operating system;

[0027] The display panel 1 is a series circuit formed by connecting LED lights and buttons, and uses the on or off of the LED lights to display the actions of various parts of the production line;

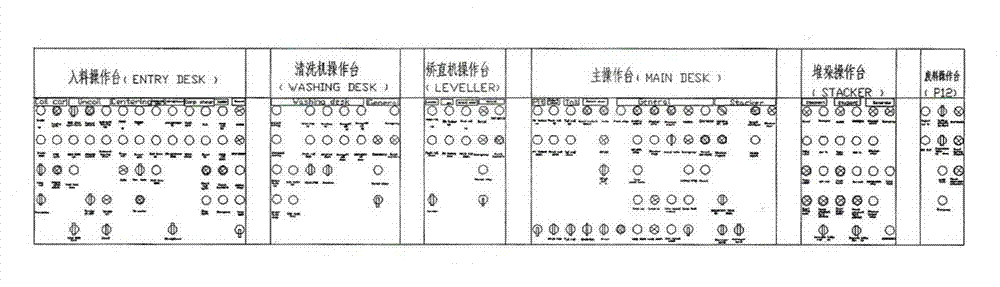

[0028] Operation button station 2, each button represents a different production action;

[0029] The simulation operations of steel coil feeding, centering, threading, entering the straightening machine, cutting and stacking processes are completed through the operation buttons and operation switches, and the operation of each button function is displayed in the form of flashing light bulbs.

[0030] A method for realizing a flashing pendulum trimming training operating system capable of providing pendulum trimming traini...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com