Malfunction setting and pendulum shear line production practical training system and implement method

An operating system and fault technology, which is applied in the field of fault setting pendulum and shearing line training operating system, can solve the problems of lack of manual pendulum and trimming, difficult use and operation, and limited skilled staff, so as to improve professional maintenance skills, The effect of reducing operational safety incidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

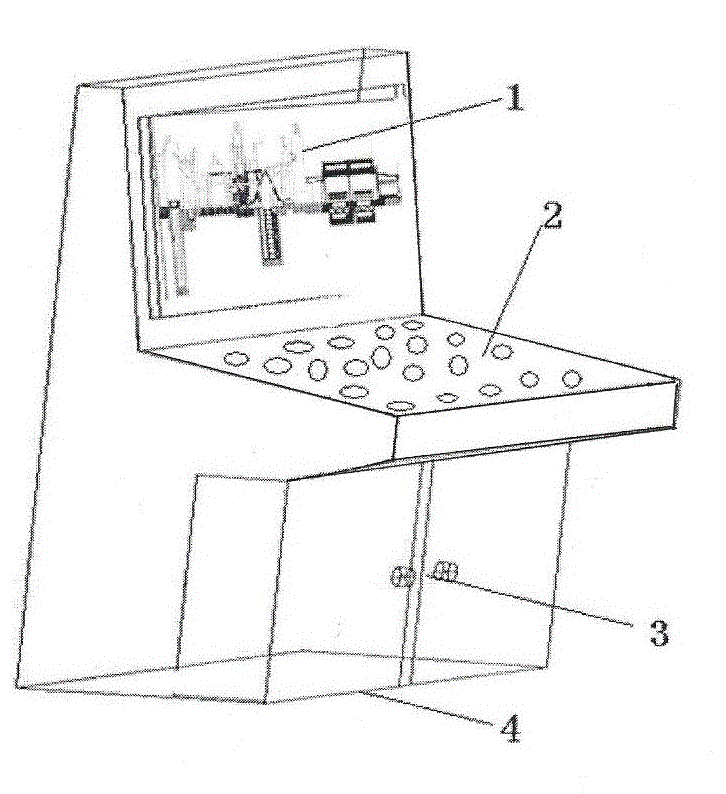

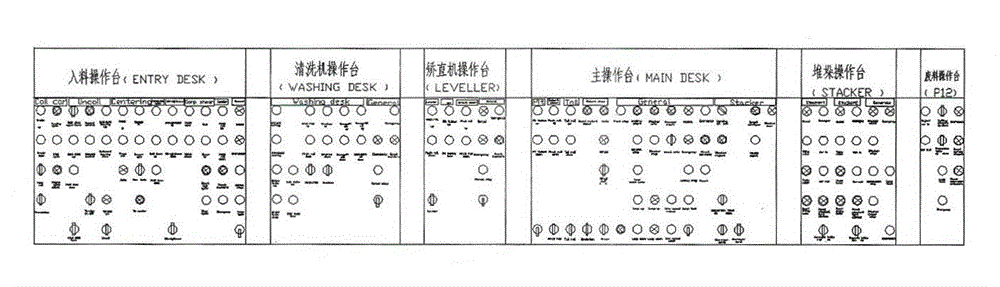

[0019] see figure 1 and figure 2 As shown, the fault setting pendulum shearing line training operating system of the present invention is composed of a display panel 1, a button operating table 2, a sliding door 3 and a base roller 4, and the base adopts a roller form, which is easy to move; the display panel 1 and the operation button table 2 can be freely opened and disassembled, and the two are connected by a series circuit, which becomes a 24V power supply after being rectified by 220V alternating current, and the power supply, operation buttons and LED lights are connected in series to form a closed loop to work. Under the premise of ensuring the normal operation of the power supply, press the operation button, the operation button is closed, the power supply, the operation button and the LED light form a closed loop, and the LED light is illuminated. When the operation button is pressed again, the operation button changes from the closed state to the open state, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com