Vortex generators for generating vortices upstream of a cascade of compressor blades

A technology of compressors and vanes, applied in the field of compressors, can solve problems such as the inability to fully satisfy the loss reduction of the rectifier area, and achieve the effect of increasing the stability range and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

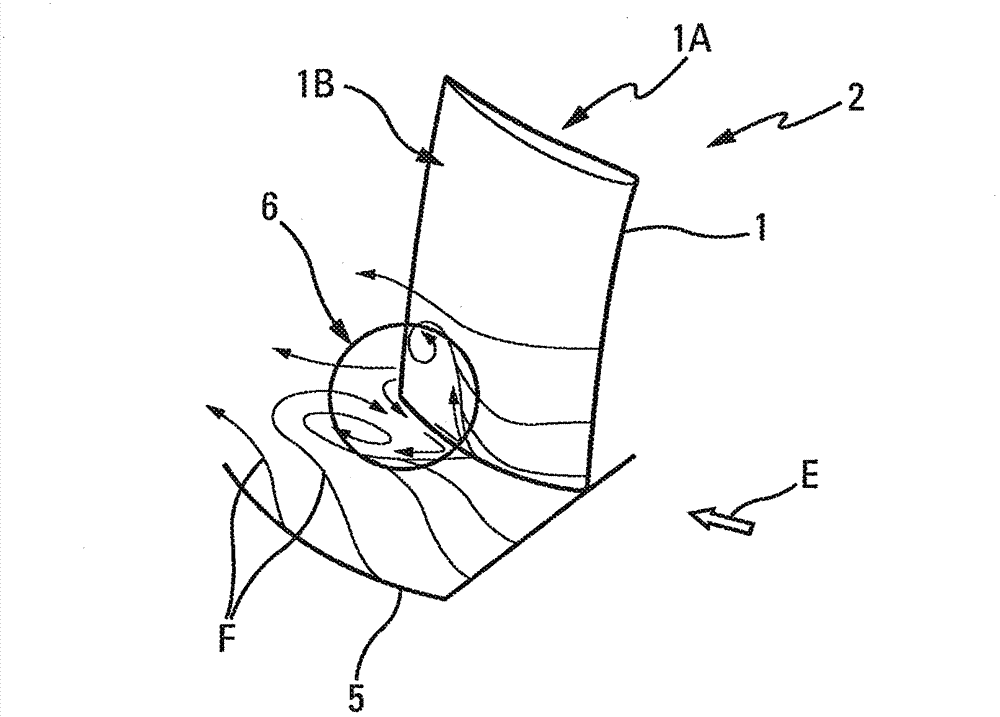

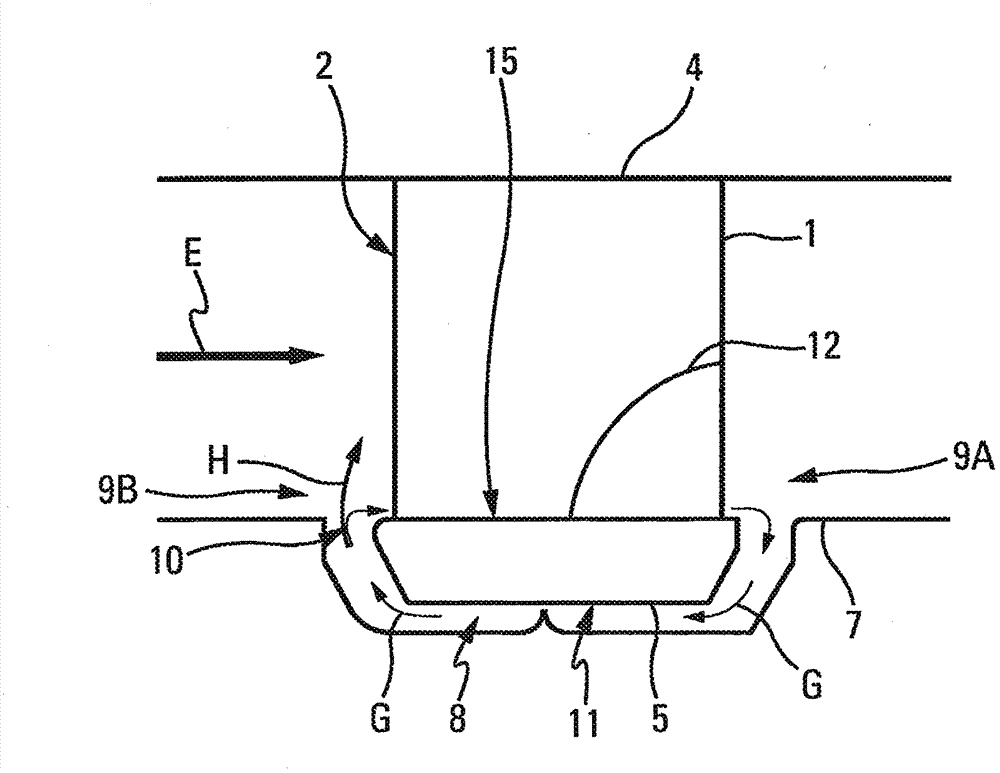

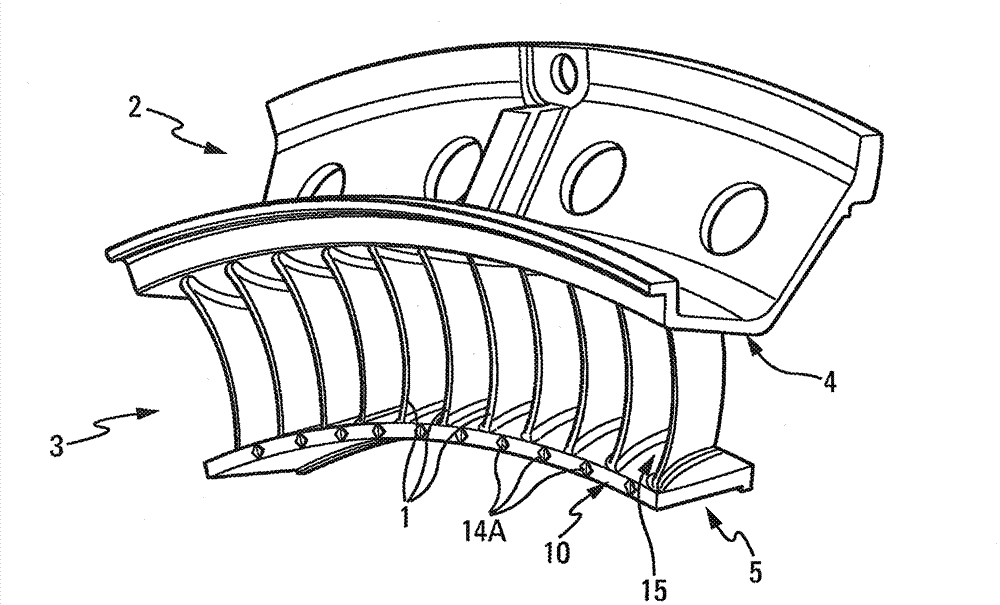

[0038] vane 1 of rectifier 2, as shown in part in image 3 and 5 as in , shown in figure 1 middle. Said rectifier 2 forms part of a compressor 3 of a turbomachine, in particular of an aircraft turbojet engine. The compressor 3 comprises, in the usual manner, a plurality of successive compression stages, each comprising a rotor 22 and a rectifier 2 (stator).

[0039] Said rectifier 2 comprises a (radial) outer shroud 4 and a (radial) inner shroud 5 , which are support shrouds for the blades 1 . Said two shrouds 4 and 5 are concentric, a plurality of vanes 1 extending substantially radially from one of said shrouds 4 and 5 to which they are fixed to the other, said blades 1 being circumferentially spaced, preferably spaced in an even manner.

[0040] Within the scope of the present invention:

[0041] - the concepts "upstream" and "downstream" are defined with respect to the direction of the main flow of air in the rectifier 2 and compressor 3; and

[0042] - The term "ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com