Sheet-shaped connecting shackle and automatic processing device as well as processing method thereof

An automatic processing, sheet-like technology, applied in the direction of fasteners, cufflinks, belt buckles, etc., can solve the problems of inability to bend flat links, unreliable links, single shape, etc., to reduce precious metal waste and compact structure. , the effect of easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] In order to fully understand the technical content of the present invention, the technical solutions of the present invention will be further introduced and illustrated below in conjunction with specific examples, but not limited thereto.

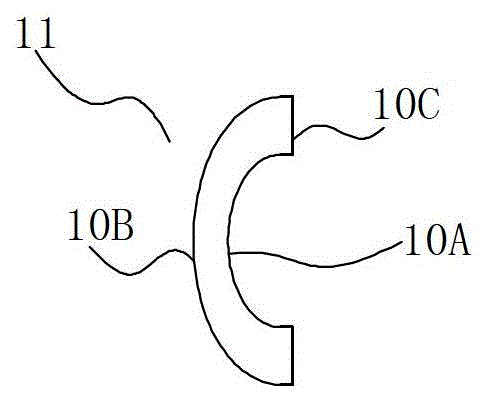

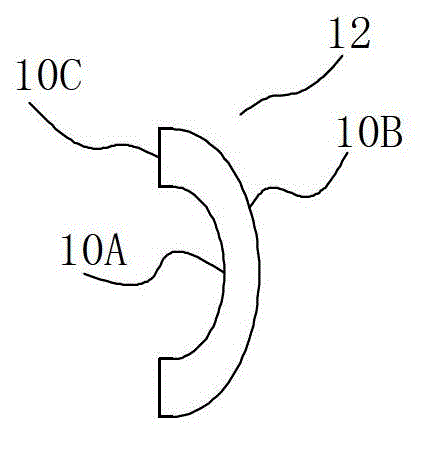

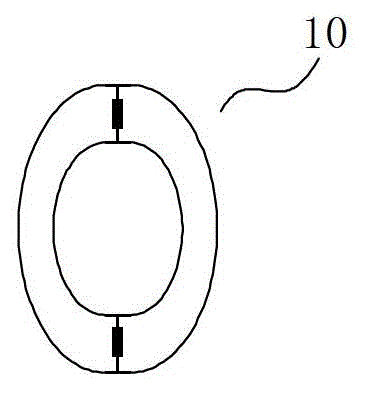

[0061] Figure 1 to Figure 3B As shown, a sheet fastener 10 of the present invention includes a first sheet body 11 and a second sheet body 12 welded to the first sheet body 11, the first sheet body 11 and the second sheet body 12 The shapes are the same, and both are provided with an inner arc portion 10A, an outer arc portion 10B, and two end portions 10C between the inner arc portion 10A and the outer arc portion 10B; the width of the inner arc portion 10A At least twice the width of the end portion 10C, in order to realize the series connection between the buckles.

[0062] in, Figure 2A with Figure 2B For butt welded structure, Figure 3A with Figure 3B For lap welding.

[0063] Such as Figure 4 to Figure 6 As shown, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com