Lateral feeding machining cutter

A cutting tool and feeding technology, which is applied in the direction of manufacturing tools, metal processing equipment, and cutting tools for lathes, etc., can solve the problem of boring the side of the annular groove on the step surface of the workpiece step hole, and the boring of the step hole of the workpiece Cutting, increasing the cost and other issues, to achieve the effect of improving the scope of application, improving the service life and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

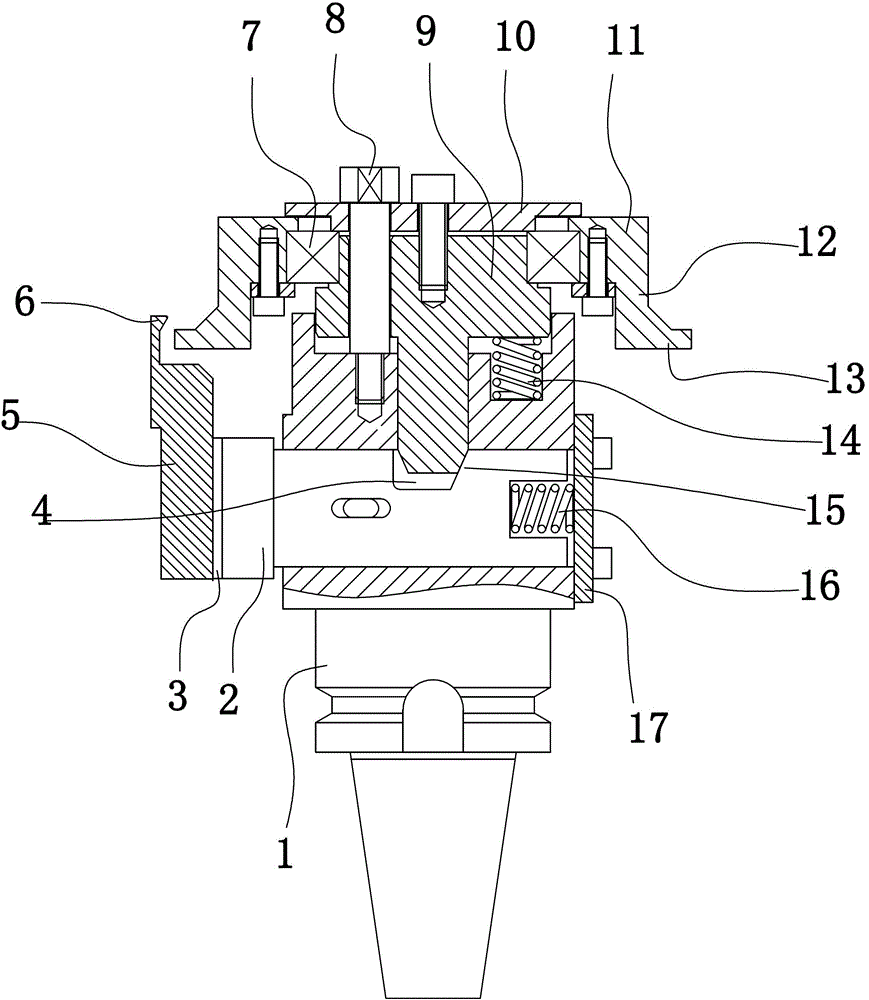

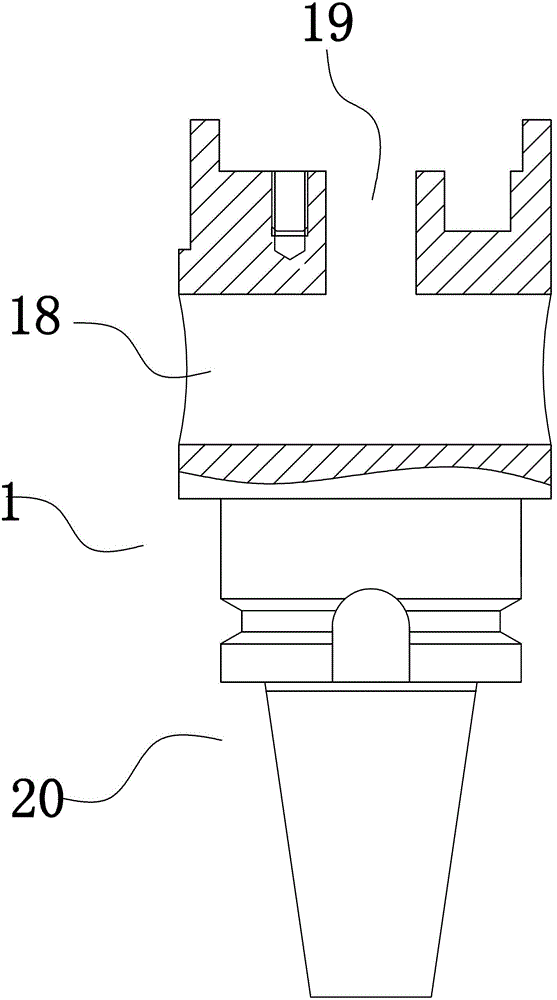

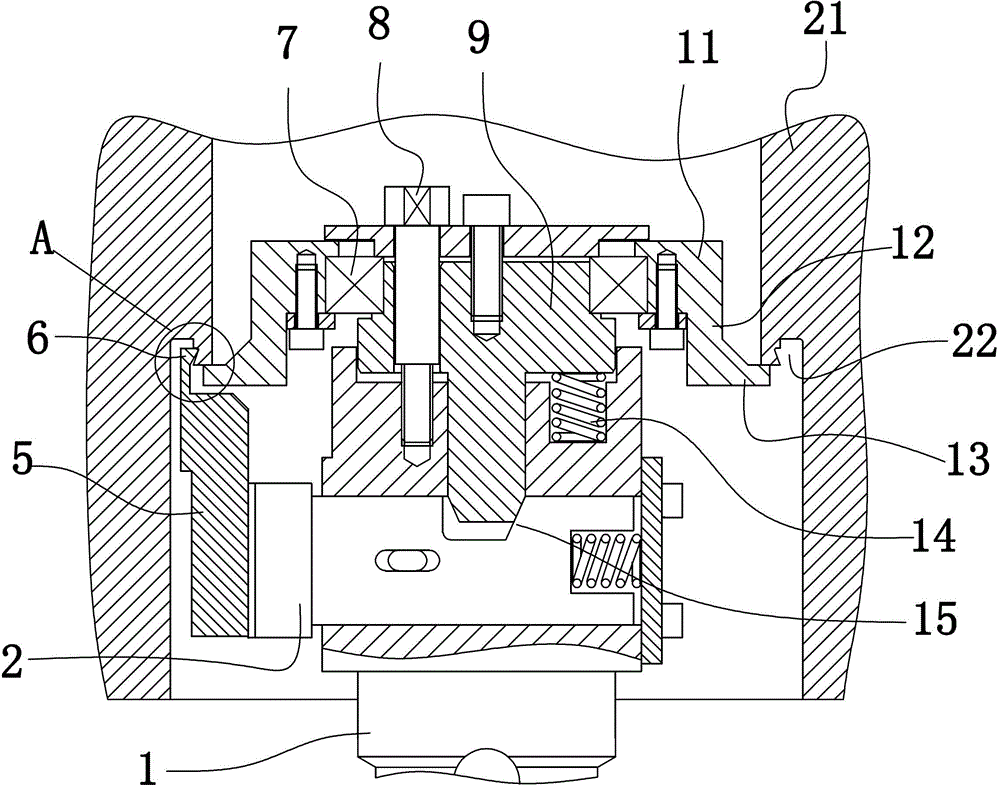

[0036] Embodiment 1: as figure 1 , figure 2 As shown, a lateral feed machining tool includes a main shaft 1, and one end of the main shaft is provided with a shank 20 connected with a cutter head of a numerical control machining center. A radial hole 18 is provided on the side of the main shaft 1 . An axial hole 19 communicating with the radial hole is provided on the end surface of the main shaft 1 opposite to the shank. The radial hole 18 is a through hole, and one end of the radial hole is provided with a blind cover 17, and the blind cover and the main shaft are connected by bolts. A slider 2 is arranged in the radial hole 18, and the cross-sections of the radial hole and the slider are circular. A keyway is provided on the side of the slider 2, a guide groove extending axially along the radial hole is provided on the side of the radial hole relative to the keyway, and a limiting block is arranged between the guide groove and the keyway. A first return spring 16 is p...

Embodiment 2

[0045] Embodiment 2: as Figure 7 , Figure 8 As shown, a side feed machining tool includes a main shaft 1, a radial hole 18 is provided on the side of the main shaft, and an axial hole 19 communicating with the radial hole is provided on the end surface of the main shaft. A slider 2 is arranged in the radial hole. A first groove 4 opposite to the axial hole is provided on the side of the slider, and a side of the first groove near the bottom of the radial hole is an inclined guide surface 15 . The inclined guide surface 15 is an arc surface, and the arc surface gradually approaches the middle of the first groove 4 from the opening end of the first groove 4 to the bottom. A mandrel 9 is slidably provided in the axial hole. A rounded corner is provided on the edge of the end surface of the mandrel near the first groove, and the arc surface of the rounded corner abuts against the arc surface of the first groove. Refer to Embodiment 1 for the rest of the structure of this emb...

Embodiment 3

[0047] Embodiment 3: A ring-shaped support sleeve is provided on the edge of the bearing seat 11 , and the ring-shaped support sleeve extends toward the slider 2 . The end of the annular support sleeve is provided with an outwardly protruding support block. The three supporting feet in Embodiment 1 are replaced by an annular supporting sleeve. Refer to Embodiment 1 for the rest of the structure of this embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com