Water gap plate for battery case mold and battery case mold

A technology of battery shell and nozzle plate, applied in the field of nozzle plate and battery shell mold, can solve the problems such as deformation of inserts 24, partial glue of battery shell rib 25, and inability to effectively balance the resultant force of inserts 24, so as to reduce the joint force. External force, improve the effect of rib partial glue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

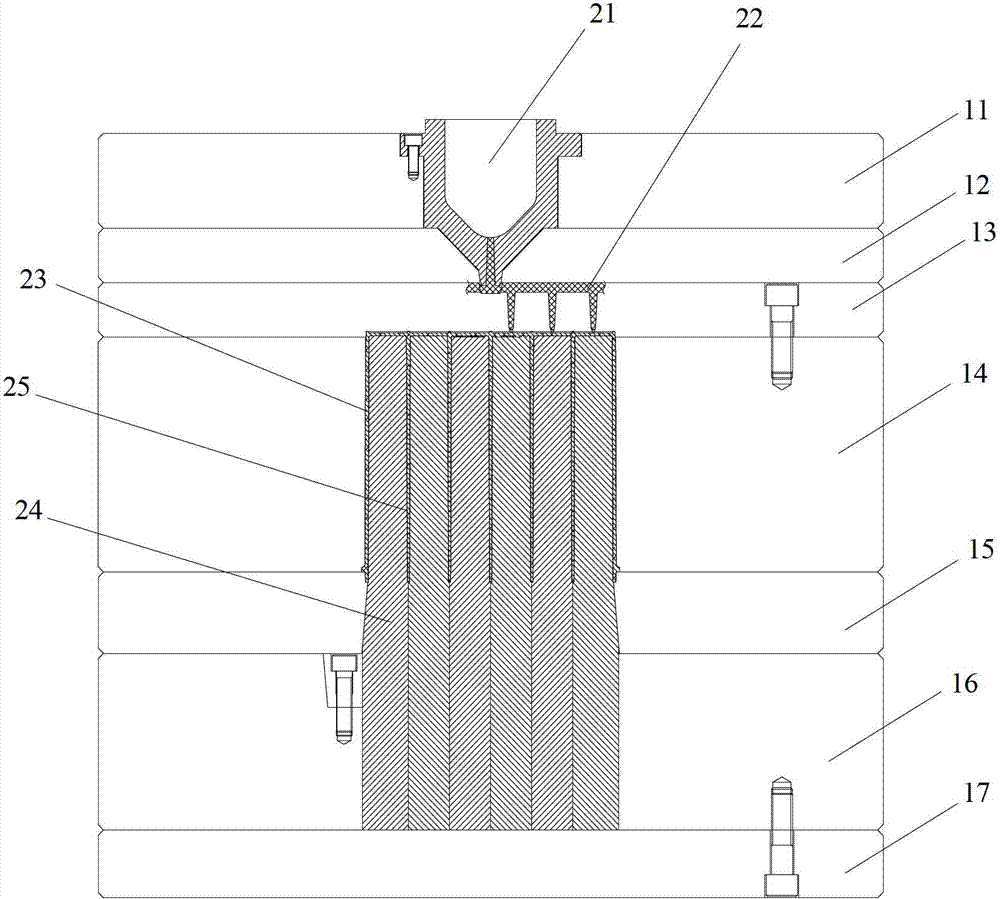

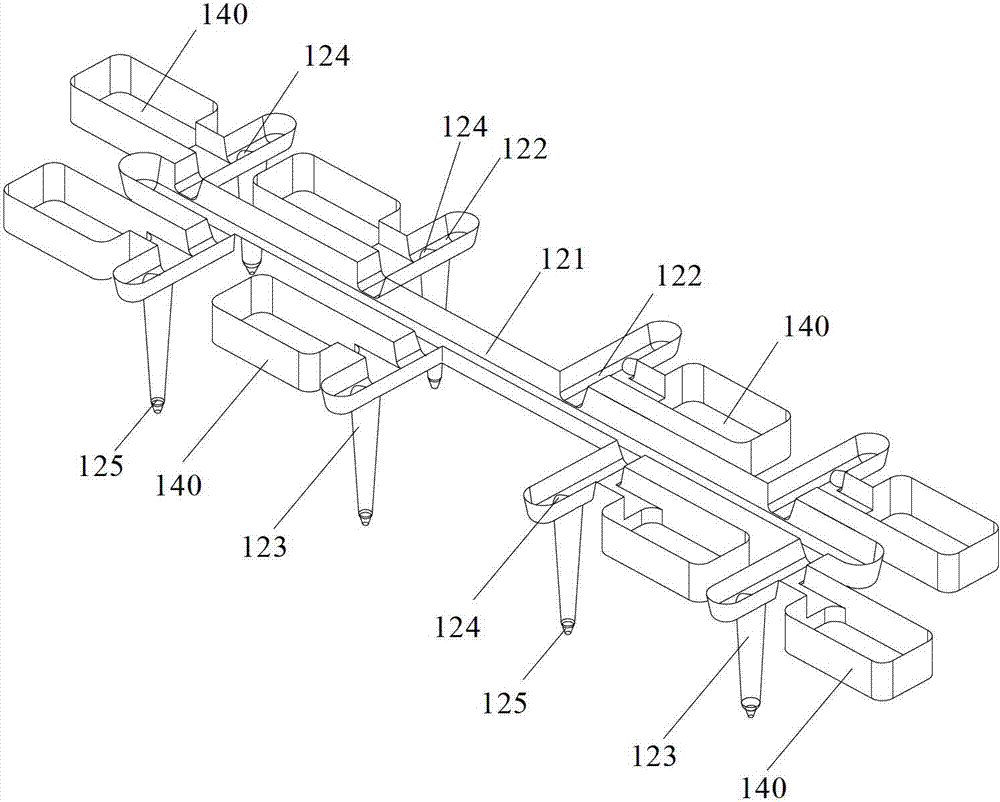

[0023] Please refer to figure 1 ,

[0024] An embodiment of the nozzle plate 100 for the battery case mold of the present application includes a substrate 110 , a flow channel structure 120 , a flow limiting valve 130 and a flow limiting valve slot 140 , and the flow channel structure 120 is embedded in the substrate 110 . The channel structure 120 includes a main channel 121, a branch channel 122 and a branch pipe 123, the branch channel 122 communicates with the main channel 121, the bottom of the branch channel 122 is provided with a first through hole 124, and the branch pipe 123 is connected to the branch channel through the first through hole 124. 122 communicates, and the lower end of the shunt pipe 123 is provided with a glue inlet point 125 . The restrictor valve 130 includes a fixed part 131 and a restrictor part 132. The fixed part 131 is arranged in the restrictor valve groove 140 and can move in the restrictor valve groove 140. When the fixed part 131 moves, it c...

Embodiment 2

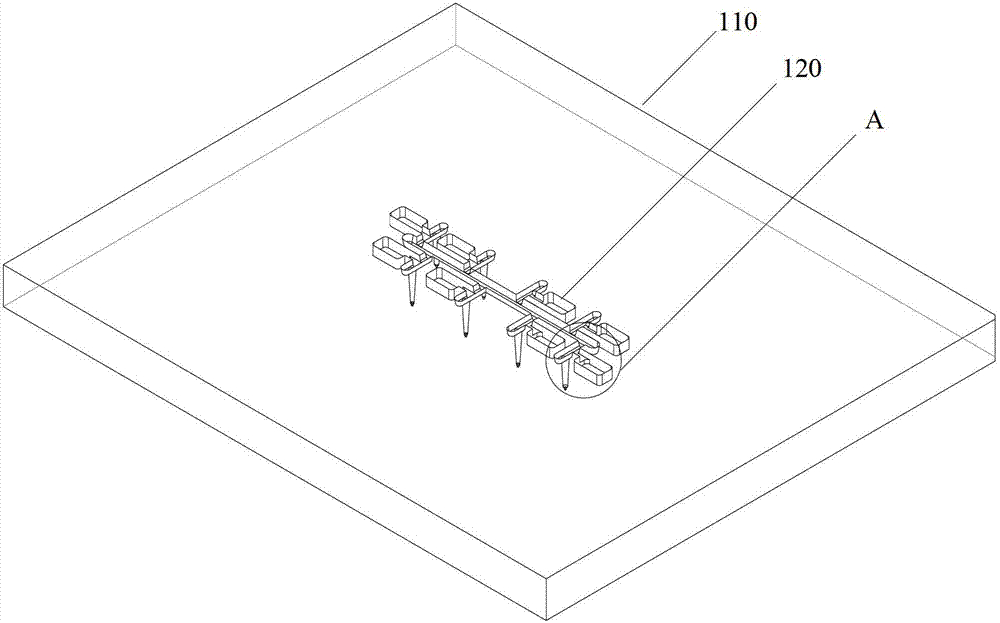

[0031] Please refer to figure 2 ,

[0032] The battery case mold of the present application includes a nozzle plate 100 for the battery case mold, and one embodiment thereof includes a substrate 110, a flow channel structure 120, a flow limiting valve 130 and a flow limiting valve slot 140, and the flow channel structure 120 is embedded in the substrate 110 in. The channel structure 120 includes a main channel 121, a branch channel 122 and a branch pipe 123, the branch channel 122 communicates with the main channel 121, the bottom of the branch channel 122 is provided with a first through hole 124, and the branch pipe 123 is connected to the branch channel through the first through hole 124. 122 communicates, and the lower end of the shunt pipe 123 is provided with a glue inlet point 125 . The restrictor valve 130 includes a fixed part 131 and a restrictor part 132. The fixed part 131 is arranged in the restrictor valve groove 140 and can move in the restrictor valve groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com