A splitting device for supercritical fluid chromatograph and mass spectrometer

A supercritical fluid and flow splitting device technology, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of easy vaporization of the mobile phase, low ionization degree of compounds, and decline in mass spectrometry resolution and accuracy, so as to improve product quality. Effects of degree of ionization, improvement of resolution and accuracy, and cost saving of sample analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

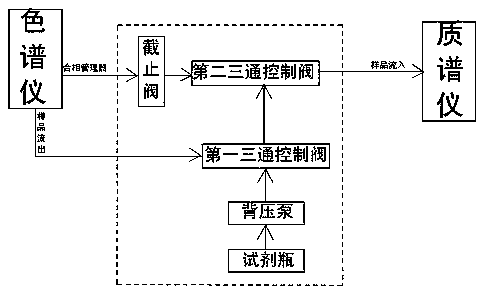

[0016] refer to figure 1 , the embodiment of the present invention discloses that a supercritical fluid chromatograph and a mass spectrometer are combined with a splitting device, including a reagent bottle, a back pressure pump, a first three-way control valve, a second three-way control valve and a stop valve, One inlet port of the first three-way control valve is used to communicate with the sample outflow pipeline of the chromatograph, and the other inlet port communicates with the reagent bottle through the back pressure pump, the reagent bottle is filled with methanol, and the back pressure pump is used to communicate with the reagent bottle. The pressure pump can pump the methanol in the reagent bottle to the first three-way control valve, and the flow rate of the back pressure pump is 0.3ml / min; the outlet port of the first three-way control valve is connected to one of the second three-way control valve The other inlet port of the second three-way control valve is use...

Embodiment 2

[0020] In embodiment 2, sample, instrument, instrument operation method are identical with the sample, instrument, instrument operation method in embodiment 1, difference is: what fills in the reagent bottle is the methanol solution that contains 10mMol ammonium formate.

[0021] Finally, the resolution of the mass spectrum is 18327, and the mass spectrum peak intensity of the antioxidant is 2.7*10 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com