Printing device for pannel

A printing device and panel technology, applied in printing, printing machines, rotary printing machines, etc., can solve problems such as no consideration, and achieve the effect of shortening the delivery time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

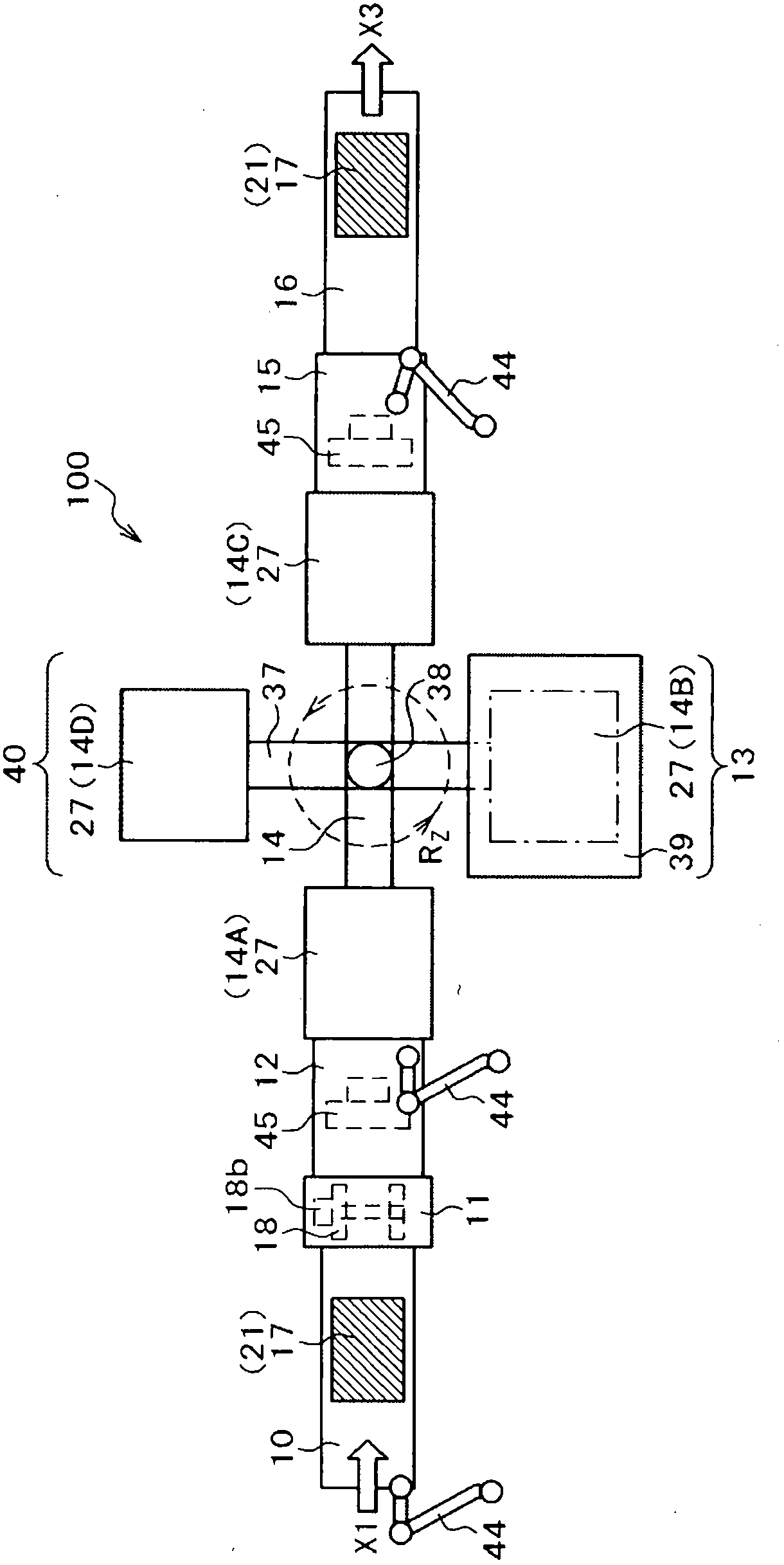

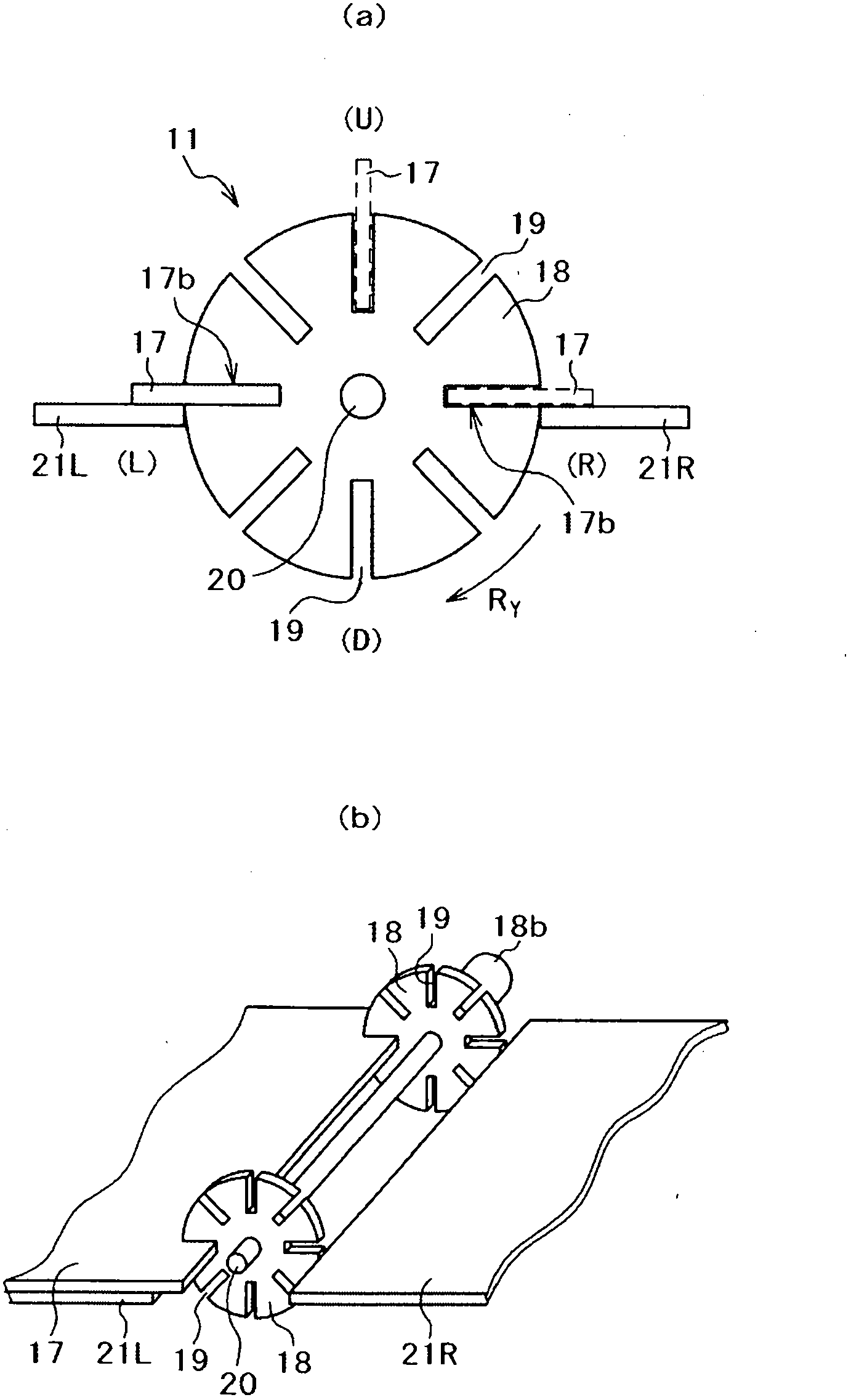

[0023] Next, an embodiment of the panel printing device according to the present invention will be described with reference to the drawings. figure 1 is a top view of an embodiment of the printing device 100 . Between the stocker 10 on the carry-in side in the horizontal direction and the stage conveyor 16 on the carry-out side arranged in a straight line, there are four worktables 14A to 14D arranged at intervals of 90 degrees. workbench14.

[0024] On the downstream side of the stocker 10 on the carry-in side in the carry-in direction, a substrate reversing mechanism 11 and a first inspection unit 12 , which will be described in detail later, are provided. The second inspection unit 15 is provided between the rotary table 14 and the stage conveyor 16 on the carry-out side. The printing unit 13 is arranged in a direction (X direction) perpendicular to the direction in which the stocker 10 and the stage conveyor 16 are arranged, that is, a direction passing through the cente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com