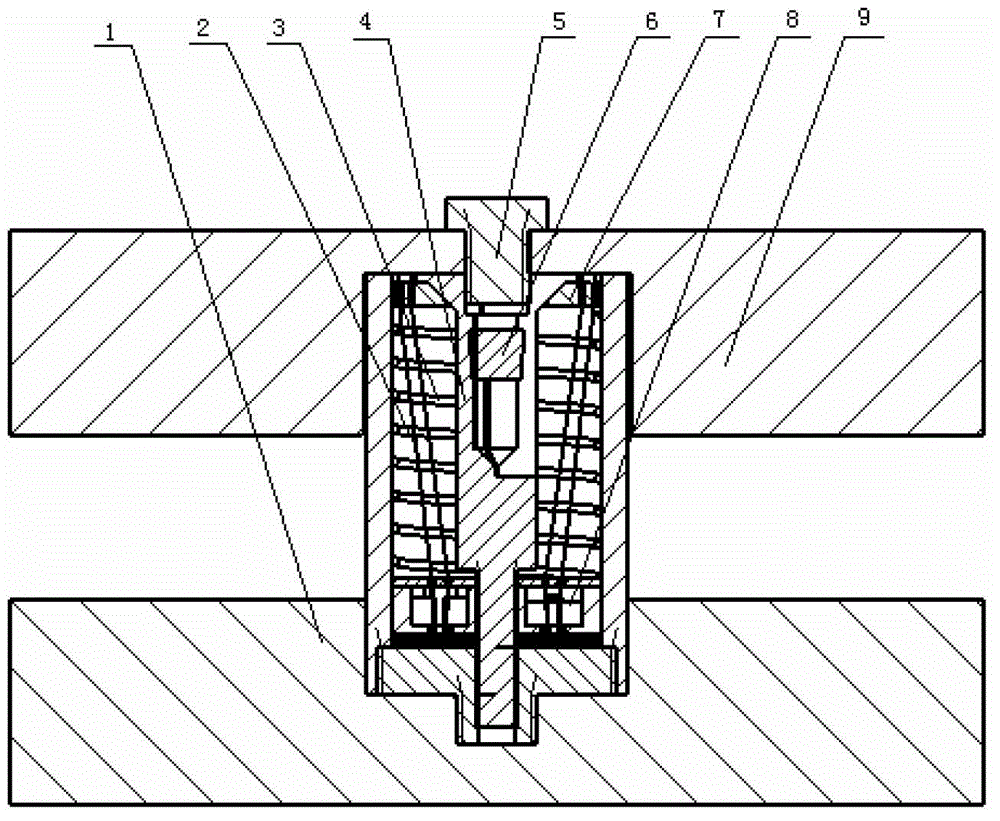

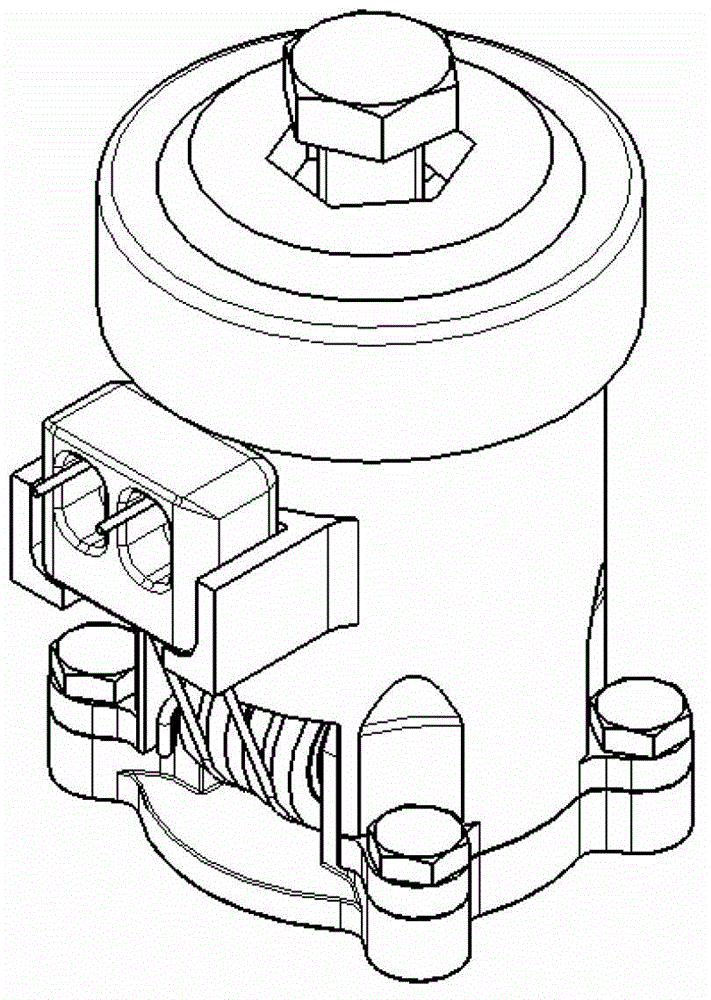

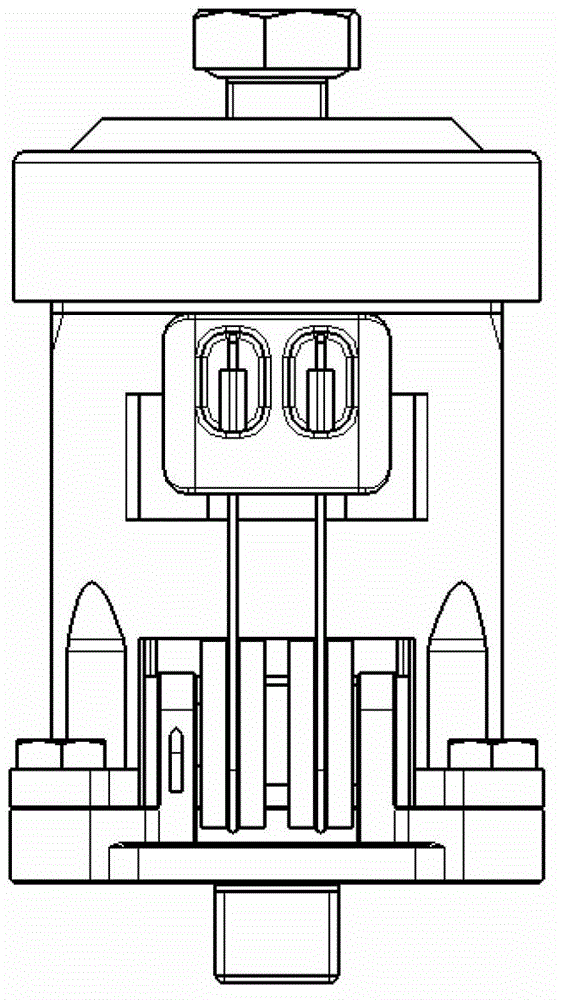

Connecting and unlocking mechanism driven by SMA (Shape Memory Alloy) wire

A technology of unlocking mechanism and driving device, which is applied in the docking device of aerospace vehicles, etc., can solve problems such as incomplete unlocking, and achieve the effects of improving reliability, increasing length, and increasing margin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] References to Related Applications This specification refers in its entirety to Chinese Patent Application No. 200710177157.1 "High Temperature Resistant Shape Memory Alloy Wire Fastening Device" submitted by the applicant on November 12, 2007.

[0031] For the application of the present invention, the "shape memory characteristic" of SMA (shape memory alloy) material refers to: the material is stretched and deformed at a certain low temperature, and its deformation cannot be fully restored after unloading, leaving residual deformation. However, as long as it is heated to a higher temperature, the residual deformation disappears and returns to the original unstretched shape, which is manifested as "memorizing the shape at a lower temperature", and a large amount of force is generated during the recovery process. Resilience.

[0032] In engineering, SMA wires and springs are usually combined to form a driving element, that is, the SMA wires and springs are connected to e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com