Method for canceling center coke charging of blast furnace

A blast furnace, ore-coke ratio technology, applied in blast furnaces, blast furnace details, furnaces, etc., can solve problems such as poor central coke cancellation and poor blast furnace operation status

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The method for canceling coking at the center of the blast furnace provided by the embodiment of the present invention includes:

[0021] The first step is to control the blast furnace by stabilizing the gas intensity at the edge of the blast furnace and increasing the gas intensity at the center of the blast furnace when the operation of the blast furnace is poor, so that the operation of the blast furnace tends to be relatively stable. This step also includes the following three aspects:

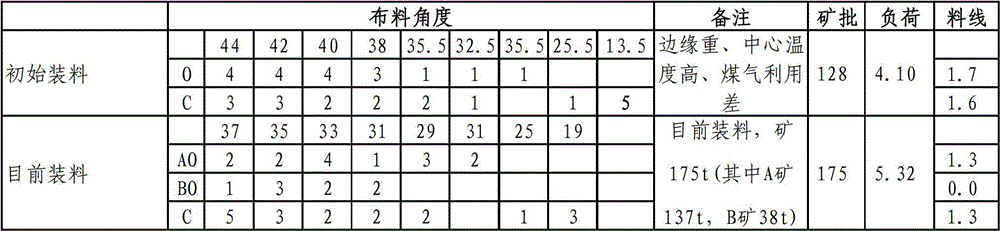

[0022] First of all, the determination and adjustment of the charging system. According to the conditions of raw materials and fuels, a standard is provided for judging the matching of the blast furnace edge and center temperature, that is, if the two are properly matched, the pressure-volume relationship is stable, that is, at the full wind level (full wind level = blast furnace effective volume * 1.5 ) The downwind volume and wind pressure fluctuations are small, except for the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com