Air-jet vortex spinning nozzle device with vortex tube having three-sectional interior structure

A technology of internal structure and nozzle device, which is applied in the direction of continuous winding spinning machine, spinning machine, textile and paper making, etc., can solve the problems of reduced operating space, influence of fiber bundle feeding, unstable airflow rotation, etc. Achieve the effect of improving strength and stabilizing airflow rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

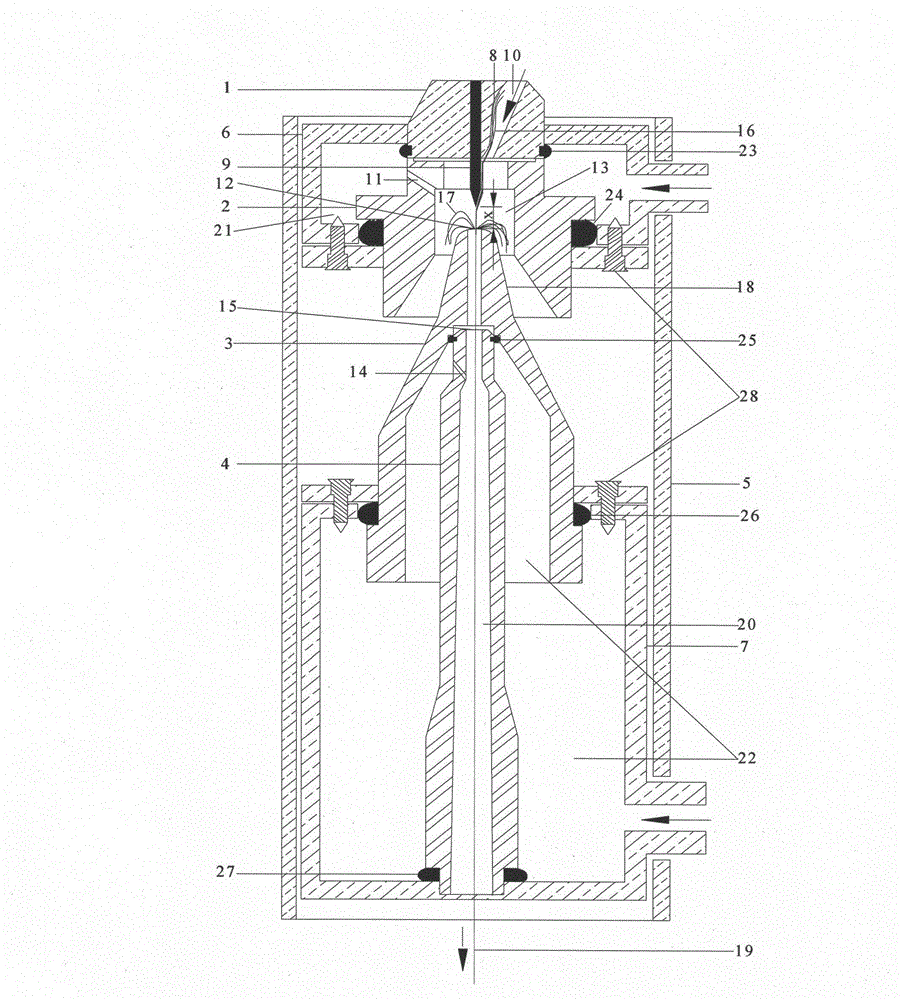

[0023] Such as figure 1 As shown, a vortex tube internal structure provided by the present invention is a three-stage air-jet vortex spinning nozzle device, which includes a guide body 1, a vortex tube 2, a cone body 3, a yarn guiding tube 4 and a fixed housing bracket 5. The guide body 1 and the vortex tube 2 are installed in the front copper cover 6 through screws 28 to form the first part of the nozzle, and the conical body 3 and yarn drawing tube 4 are installed in the rear end copper cover 7 through the screws 28 to form the second part of the nozzle. The first part of the nozzle and the second part of the nozzle are separated. When spinning, the two are assembled into one by fixing the housing bracket 5, and the fiber inlet 12 of the conical body 3 of the vortex chamber 13 is connected to the fiber inlet 12 after assembly. ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap