Subzone washing machine enabling washings to be turned over from bottom to top

A bottom-up, washing machine technology, applied in the field of washing machines, can solve the problems of complex structure, insignificant movement in the up and down direction, and the washing rate needs to be improved, and achieves the effect of improving the washing rate and reducing the entanglement of clothes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

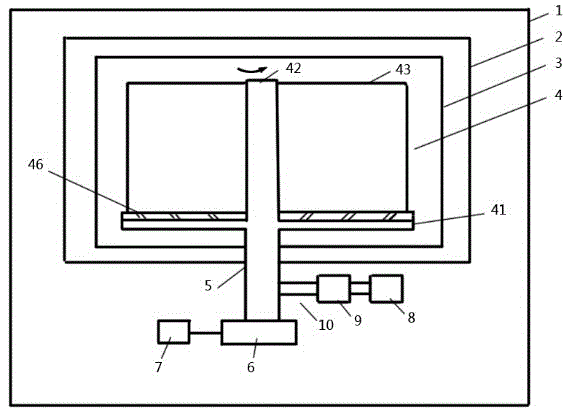

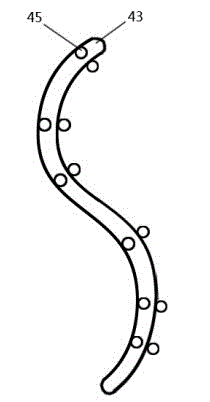

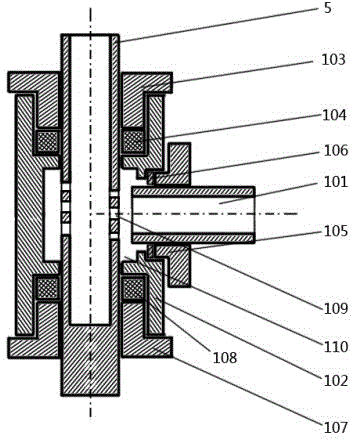

[0018] A partitioned washing machine that makes laundry tumble from bottom to top, comprising: a casing 1, forming an appearance; a water tank 2, vertically hoisted on the casing 1 through two spring shock absorbers, and containing washing water; a drum 3, Coaxially and rotatably placed in the water tank 2 to accommodate the clothes; there is a pulsator 4 in the center of the bottom of the drum, the pulsator is connected to the gearbox 6 through the hollow rotating shaft 5, the gearbox is connected to the motor 7, and the motor 7 drives the variable speed The box 6 drives the pulsator 4 to rotate, and the pulsator 4 is formed by the following structure: a chassis 41, which is fixed to the rotating shaft 5; Hollow structure; a partition plate 43 formed protruding from the side wall of the columna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com