Power supply power device radiation structure

A heat dissipation structure and power supply technology, applied in the direction of cooling/ventilation/heating transformation, etc., can solve problems such as difficult to meet the vibration conditions and damage of automobiles, and achieve the effect of improving the anti-seismic effect and improving the heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

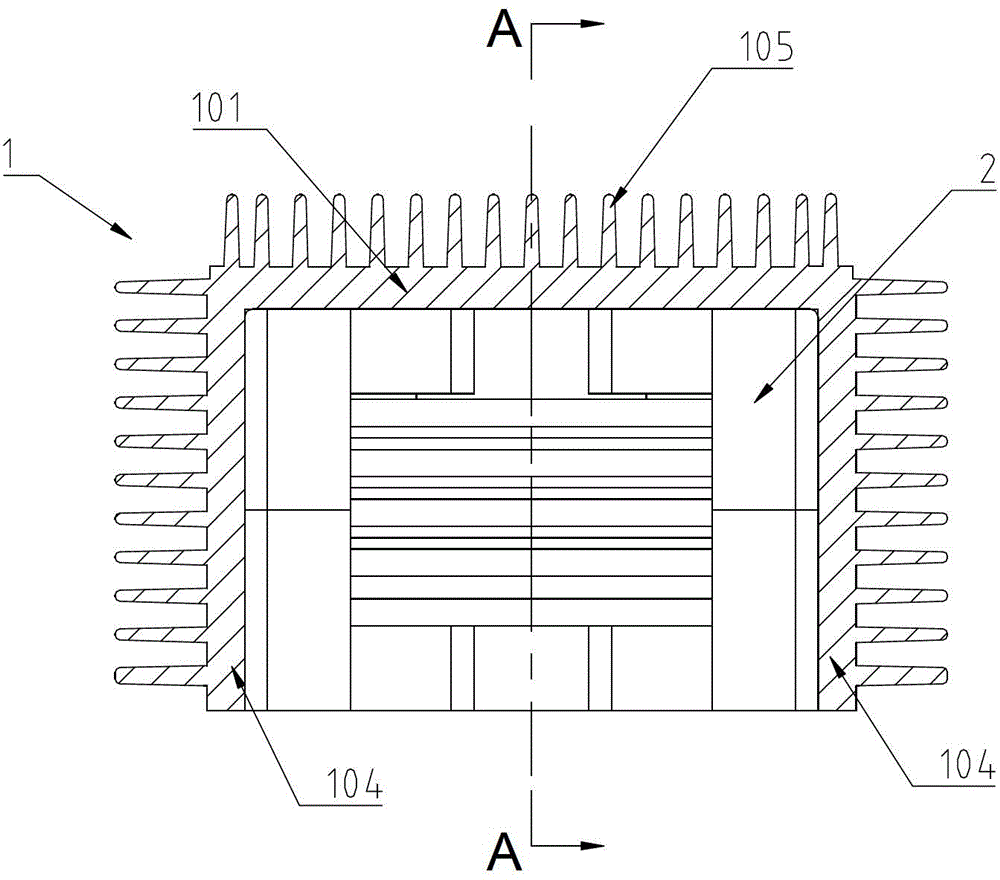

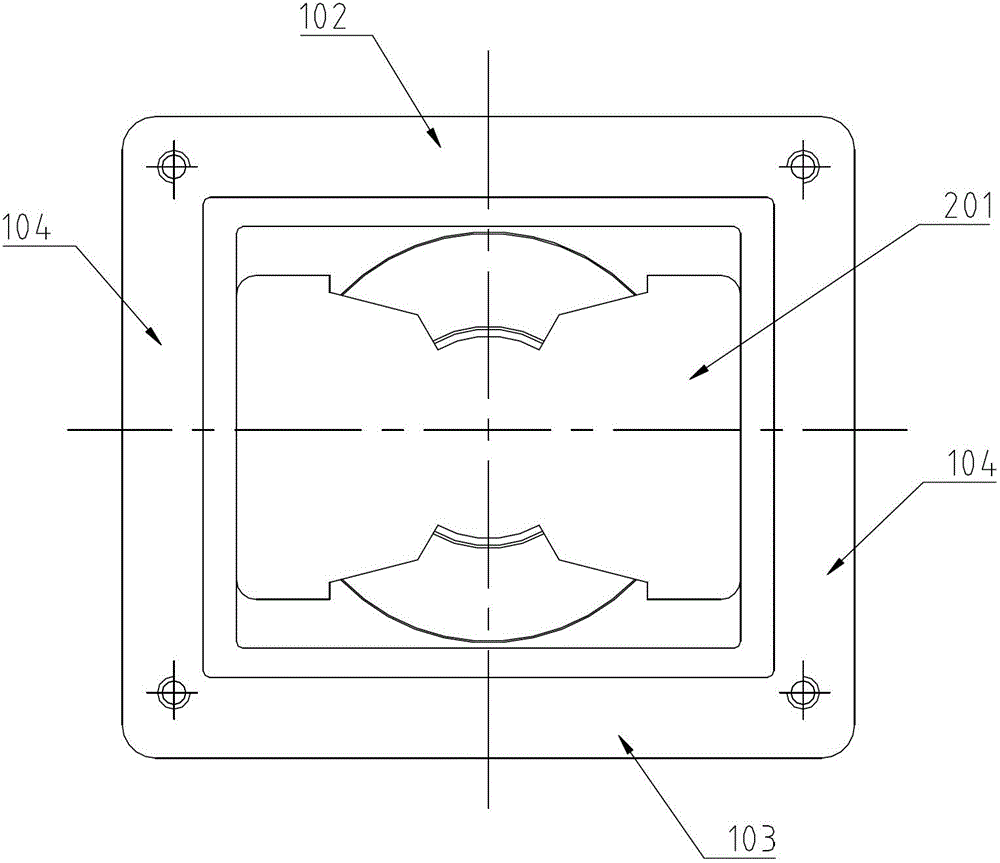

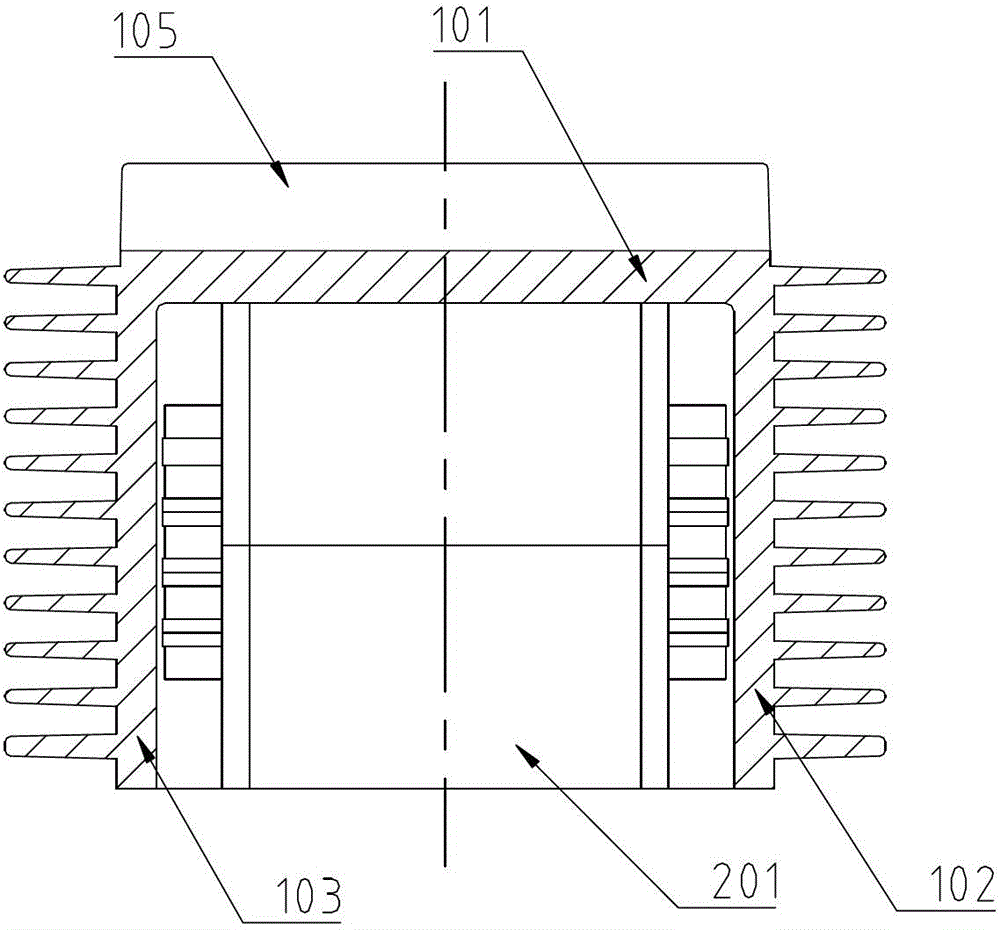

[0028] exist Figure 1 to Figure 3 The heat dissipation structure of the power device according to Embodiment 1 of the present invention includes a heat sink 1 and a transformer 2, the heat sink 1 includes a top plate 101, a front plate 102, a rear plate 103 and two side plates 104, the top plate 101 and two The side plates 104 form a U-shaped structure; the front plate 102 and the rear plate 103 are respectively connected with the top plate 101 and the side plates 104 to form a box-shaped structure with an open lower end.

[0029] The open groove formed by the top plate 101 , the front plate 102 , the rear plate 103 and two side plates 104 is the transformer 2 installation groove; the transformer 2 is installed in the open groove.

[0030] The magnetic core 201 of the transformer 2 includes a top surface and two side surfaces. The top surface and two side surfaces of the magnetic core 201 are attached to the top plate 101 and the two side plates 104 of the radiator 1 respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com