Non-tillage fertilizing, film spreading, bunch planting and earthing combined machine

A combined working machine and soil-covering technology, applied in agricultural machinery and implements, agriculture, shovels, etc., can solve problems such as timely planting of land, shortage of rural labor force, soil moisture loss, etc., to reduce operating procedures, maintain moisture germination rate, reduce The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

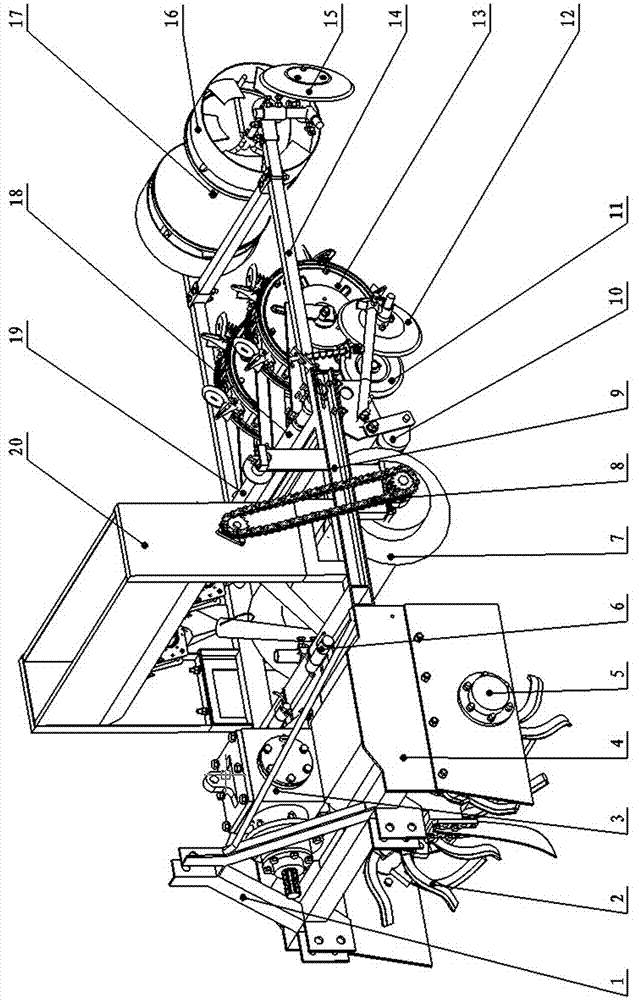

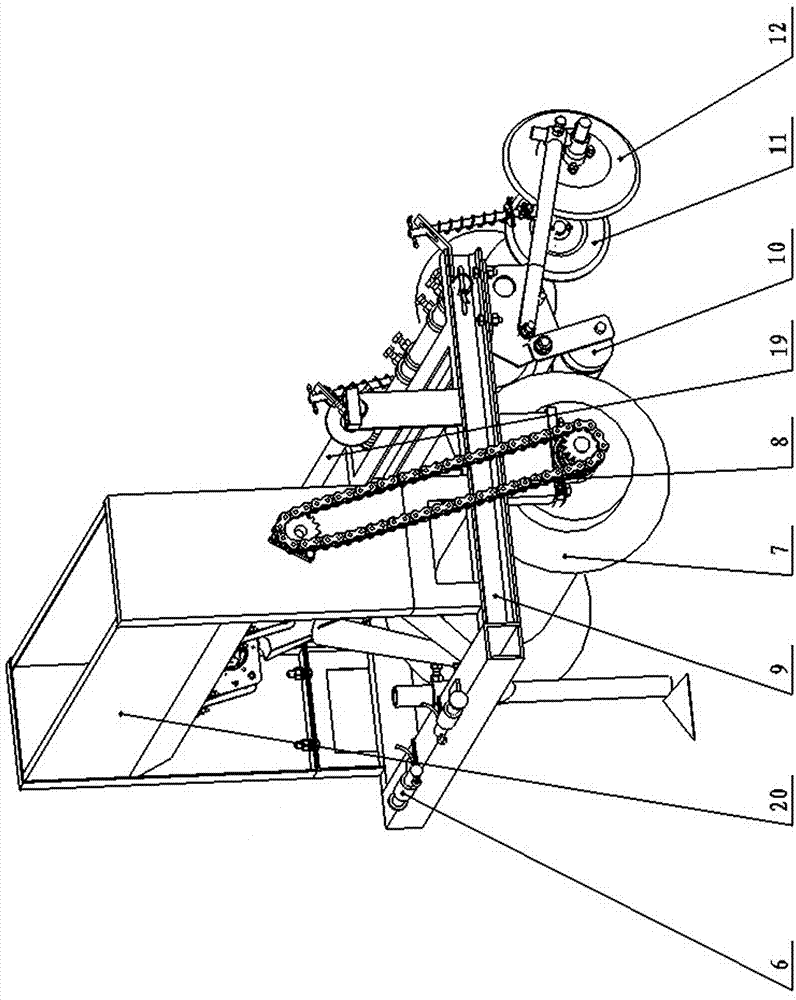

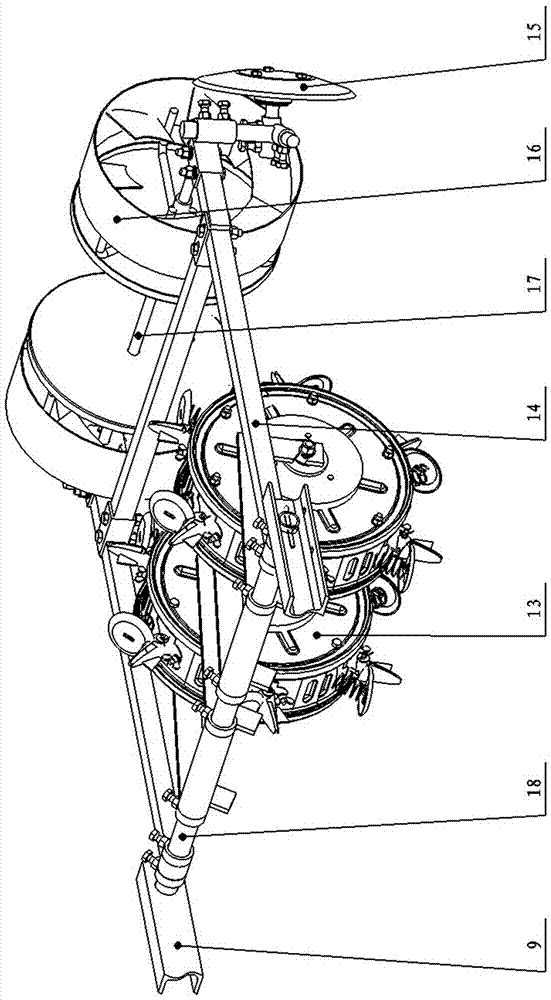

[0015] A no-tillage fertilization, film, on-demand, and soil-covering combined operation machine is composed of four parts:

[0016] The rotary cultivating mechanism is installed in front of the implement, connected with the tractor through the three-point hitch 1, and the power output shaft of the tractor is connected with the reversing gear box 3, and the rotary tiller frame 4 is installed at the front end of the implement frame 9. The top of the front end of the tiller frame 4 is connected with the three-point hitch 1, the reversing gear box 3 is mounted on the upper end of the rotary tiller frame 4, and the bottom of the rotary tiller frame 4 is connected with the rotary tiller knife shaft 5, and the rotary tiller knife Rotary cultivator blade 2 is housed on the shaft 5, and rotary cultivator cutter shaft 5 rotates rotary cultivator blade 2 to break up soil and root stubble, and the root stubble after smashing is buried in soil.

[0017] The fertilization shaping and suppr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com