Hay cutter

A guillotine machine and guillotine technology, which are applied in agricultural machinery and implements, cutting equipment, applications, etc., can solve the problems of inflexible movement, poor safety performance, low production efficiency, etc., and achieve flexible movement, long service life, and structure. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

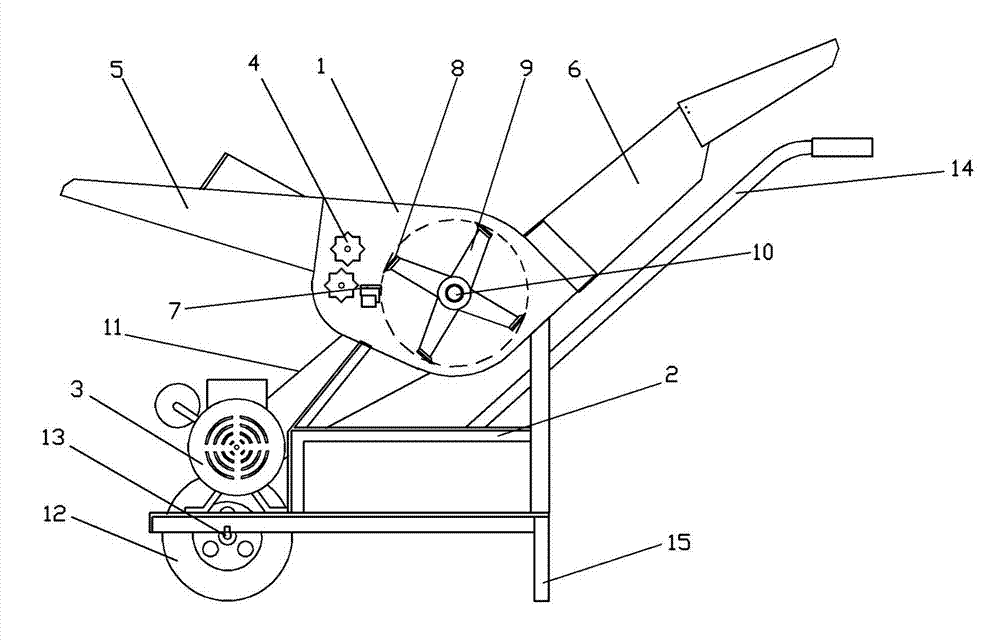

[0014] A hay cutter, comprising a housing 1, a machine base 2, a motor 3, two grazing wheels 4 and a hay cutter device, the housing 1 and the motor 3 are respectively fixed on the machine base 2, and one side of the housing 1 is fixed There is a grass-input bucket 5, and the other side is fixed with a grass-out bucket 6, and an orienting plate 16 is fixedly arranged at the exit of the grass-out bucket 6, and two grazing wheels 4 are fixed on the casing 1 by shafts up and down. Inside, and corresponding to grass bucket 5. The mowing device includes a fixed knife 7, four moving knives 8 and a knife holder 9, the fixed knife 7 is fixedly arranged in the housing 1, and is located at the rear of the grazing wheel 4, and the four moving knives 8 are respectively fixed on the knife holder 9, the knife rest 9 is arranged in the housing 1 through the rotating shaft 10, and the rotating shaft 10 is connected with the output shaft of the motor 3 through the belt 11. The key point is tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com