Efficient UV (Ultra Violet) curing equipment with cold air flow guide and heat pipe radiation functions

A technology for curing equipment and heat pipe radiators, applied in lighting and heating equipment, indirect heat exchangers, devices for coating liquids on surfaces, etc. Anti-aging performance, good air supply effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements.

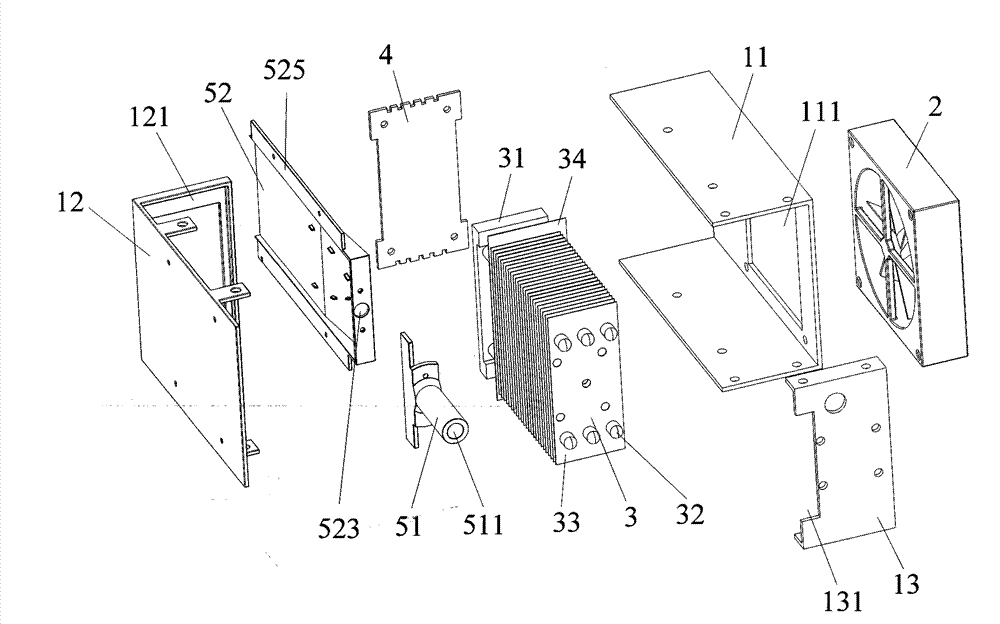

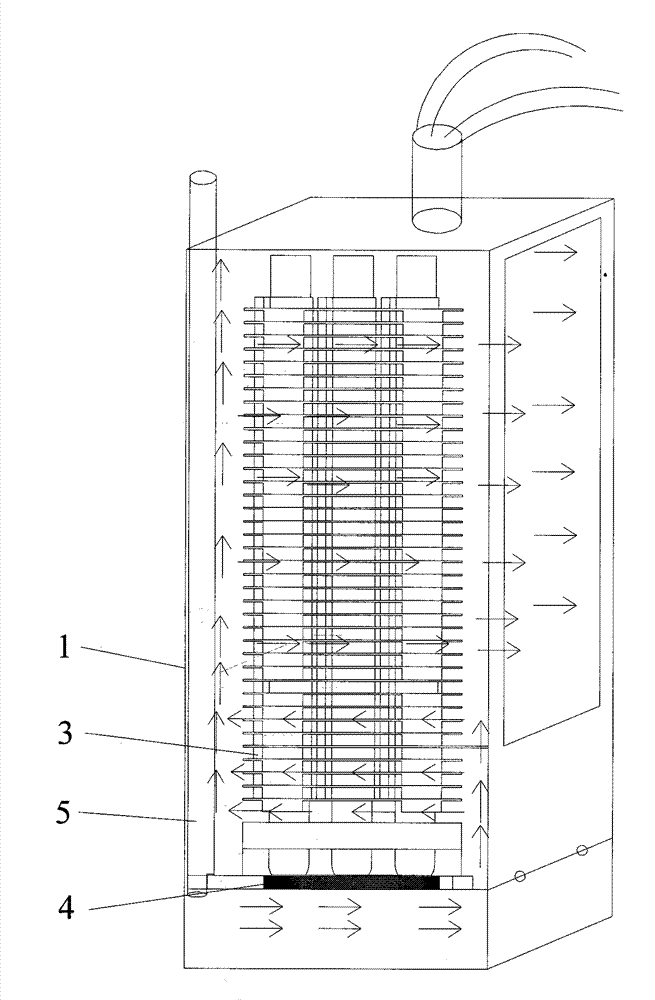

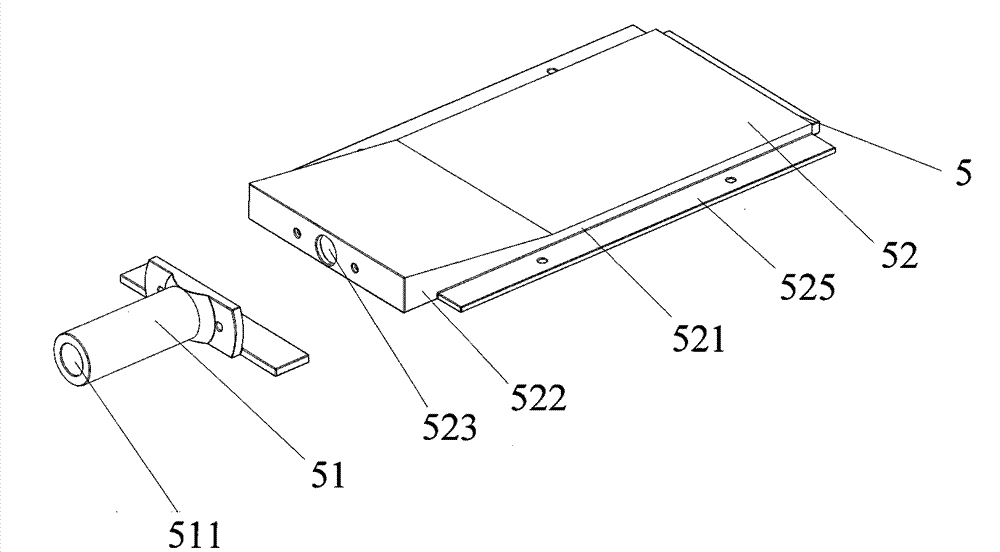

[0024] Please refer to Figure 1-6 , the described high-efficiency UV curing equipment with cold air diversion and heat pipe heat dissipation functions includes a housing 1, an exhaust fan 2, a heat pipe radiator 3, an LED light source board 4, a cooling fan (not shown) and an air supply device 5. Wherein, the exhaust fan 2 is fixed on the outside of the casing 1, the heat pipe radiator 3 and the LED light source board 4 are located inside the casing 1 and fixedly connected to each other, and the air supply device 5 is installed on the The inside of the shell 1 extends to the outside of the shell 1 .

[0025] Specifically, the casing 1 is a sealing member, and the cooling air of the cooling fan is introduced from the outside through the air supply device 5 , and the cooling gas is discharged out of the casing 1 through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com