Whole width recognition cutting machine and whole width recognition cutting method

A cutting machine and cutting head technology, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problems of low work efficiency and long identification time of laser identification cutting machine, and achieve the goal of improving production efficiency and shortening identification time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

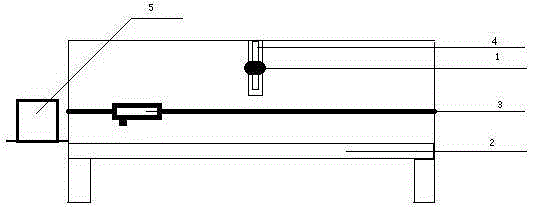

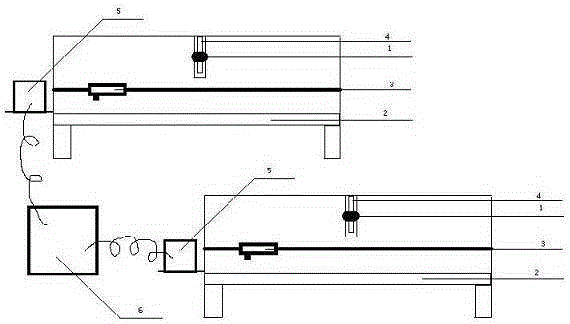

[0013] Such as figure 1 As shown, the full-width recognition cutting machine includes a full-width imager 1, a workbench 2, a cutting head assembly 3, a computer 5, and a track 4 installed in the center of the top of the workbench. The whole-width imager 1 is installed in the track 4, and can be The track 4 moves up and down, and the computer 5 is respectively connected with the imager 1 and the cutting head assembly 3 through a data transmission device. Because the main innovation in the present invention lies in the identification technology, so the specific components of the cutting head assembly 3 will not be described in detail. The cutting path in is finished cutting. When cutting the product, first lay the web with several cutting units on the workbench 2, turn on the power, the entire imager 1 moves in the track 4, and continuously adjusts according to the imaging accuracy and imaging definition during the movement The height of itself, when it is selected to a suita...

Embodiment 2

[0015] Such as figure 1 As shown, the full-width recognition cutting machine includes a full-width imager 1, a workbench 2, a cutting head assembly 3, a computer 5, and a track 4 installed in the center of the top of the workbench. The whole-width imager 1 is installed in the track 4, and can be The track 4 moves up and down, and the computer 5 is respectively connected with the imager 1 and the cutting head assembly 3 through a data transmission device. Because the main innovation in the present invention lies in the identification technology, so the specific components of the cutting head assembly 3 will not be described in detail. The cutting path in is finished cutting. When cutting the product, first lay the web with several cutting units on the workbench 2, turn on the power, the entire imager 1 moves in the track 4, and continuously adjusts according to the imaging accuracy and imaging definition during the movement The height of itself, when it is selected to a suita...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com