Four-degree-of-freedom single action platform parallel mechanism capable of achieving three-dimensional translation and one-dimensional rotation

A technology with degrees of freedom and three translations, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., to solve problems such as increasing structural complexity and complex kinematics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

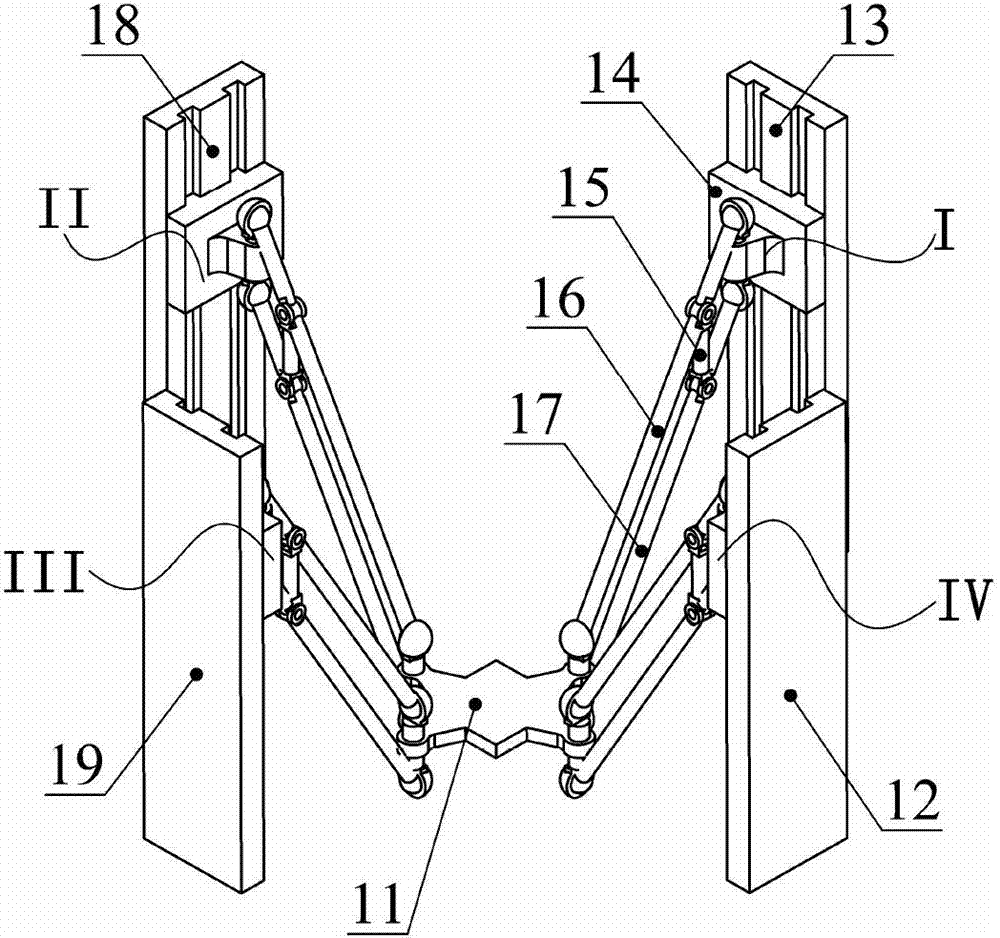

[0016] The structure of a four-degree-of-freedom single-platform parallel mechanism that can realize three translations and one rotation in this embodiment is as follows: figure 1 As shown, it includes a fixed platform composed of four fixed plates 12, 13, 18, 19, a moving platform 11 on which an actuator is installed, and the first branch chain I, the second branch chain II, the third branch chain III and the first branch chain Four branch chains IV, one end of the four branch chains is respectively connected to four fixed plates (12, 13, 18, 19), and the other end is connected to the moving platform 11, and the four branch chains are respectively connected to four fixed plates (12, 13, 19). 18, 19) and the moving platform 11 form a spatial closed-loop mechanism.

[0017] The structure of the first branch chain I, the second branch chain II, the third branch chain III and the fourth branch chain IV is exactly the same, and only the structure of the first branch chain I is mar...

Embodiment 2

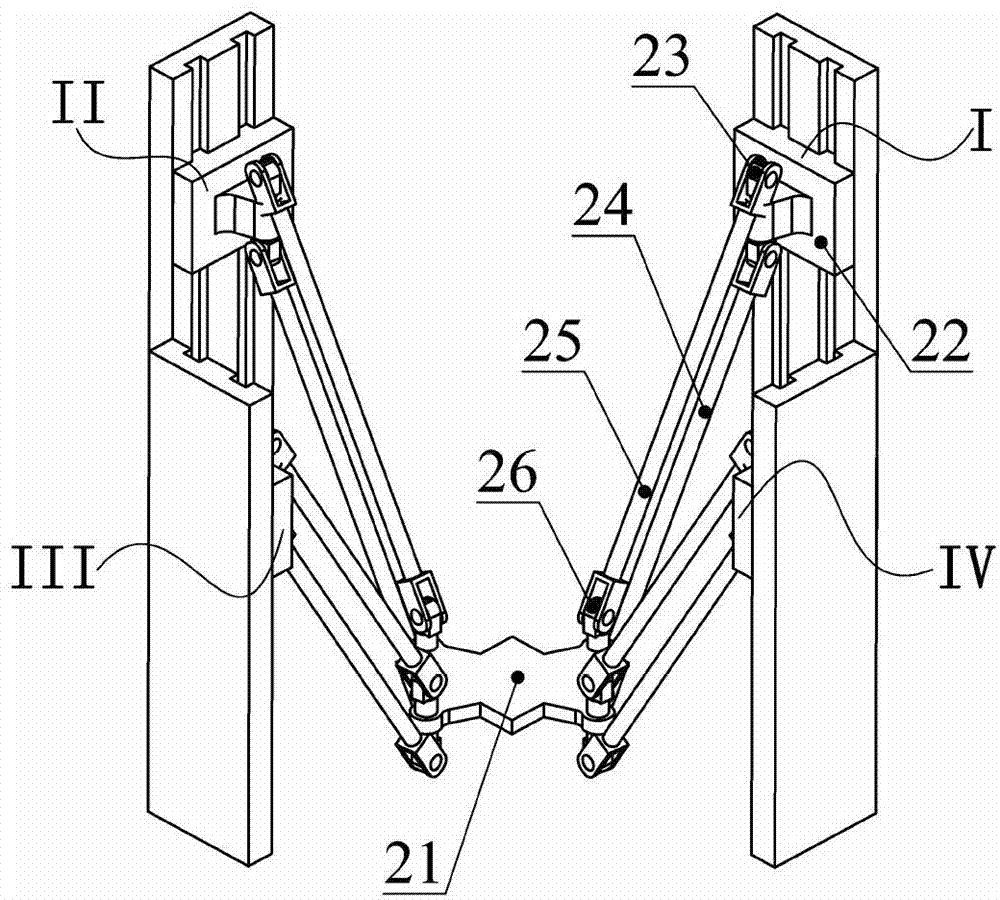

[0020] The structure of a four-degree-of-freedom single-platform parallel mechanism that can realize three translations and one rotation in this embodiment is as follows: figure 2 As shown, it is the same as the embodiment, including a moving platform 21 on which an actuator is installed, the first branch chain I, the second branch chain II, the third branch chain III and the fourth branch chain IV with the same structure, and four blocks A fixed platform composed of fixed plates. The difference between this embodiment and Embodiment 1 is that the first branch chain I, the second branch chain II, the third branch chain III and the fourth branch chain IV are all composed of a slider, a parallelogram mechanism and a kinematic pair Composition, that is, a parallelogram mechanism Pa is used. It is reflected in the specific structure: in the figure, taking the first branch chain I as an example, the slider 22 is connected with the parallelogram mechanism Pa through a rotation pai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com