Automatic label separator

A separation machine and labeling technology, applied in labeling, labeling machines, packaging, etc., can solve the problems of precision and reliability decline, structural defects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

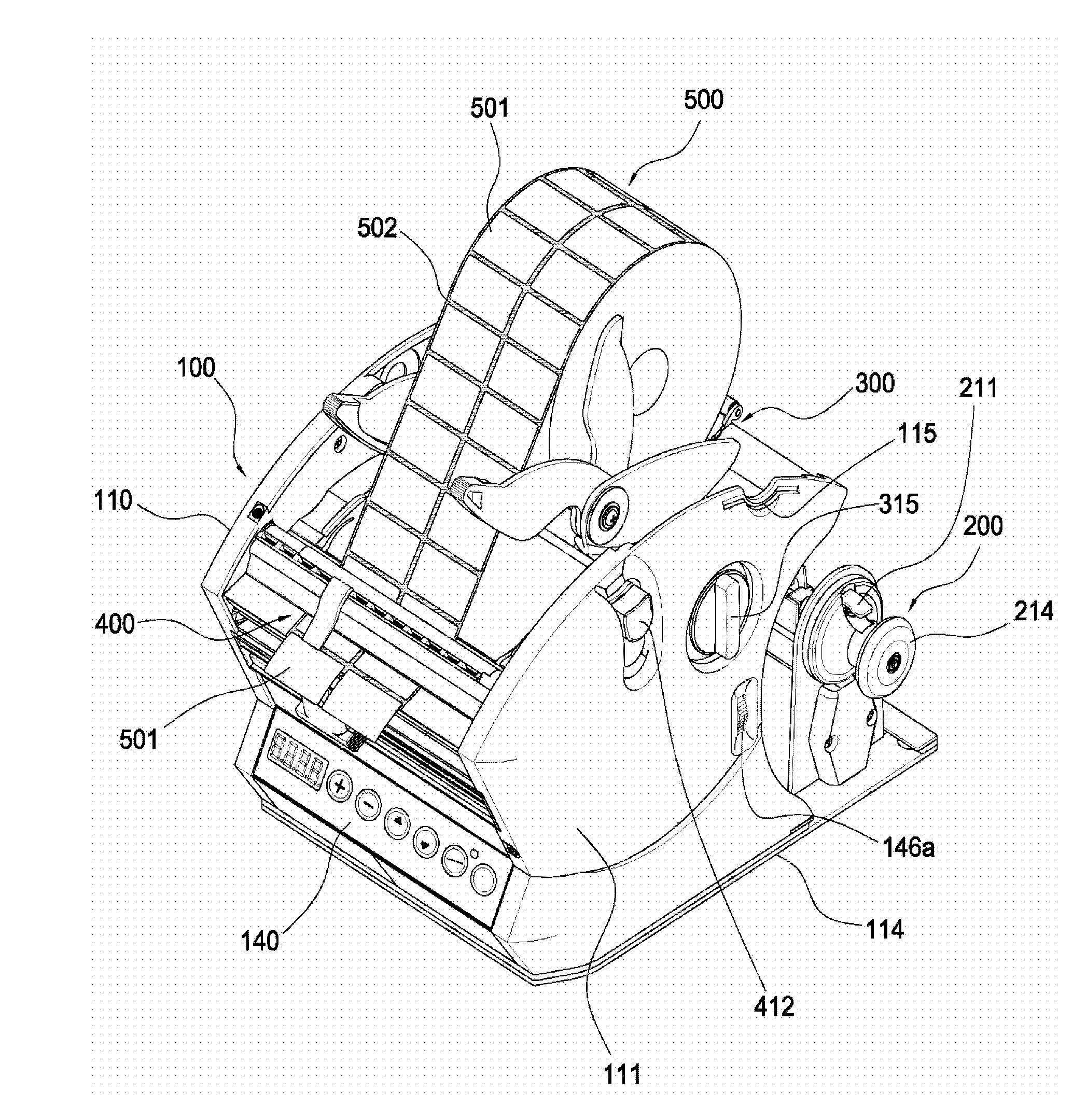

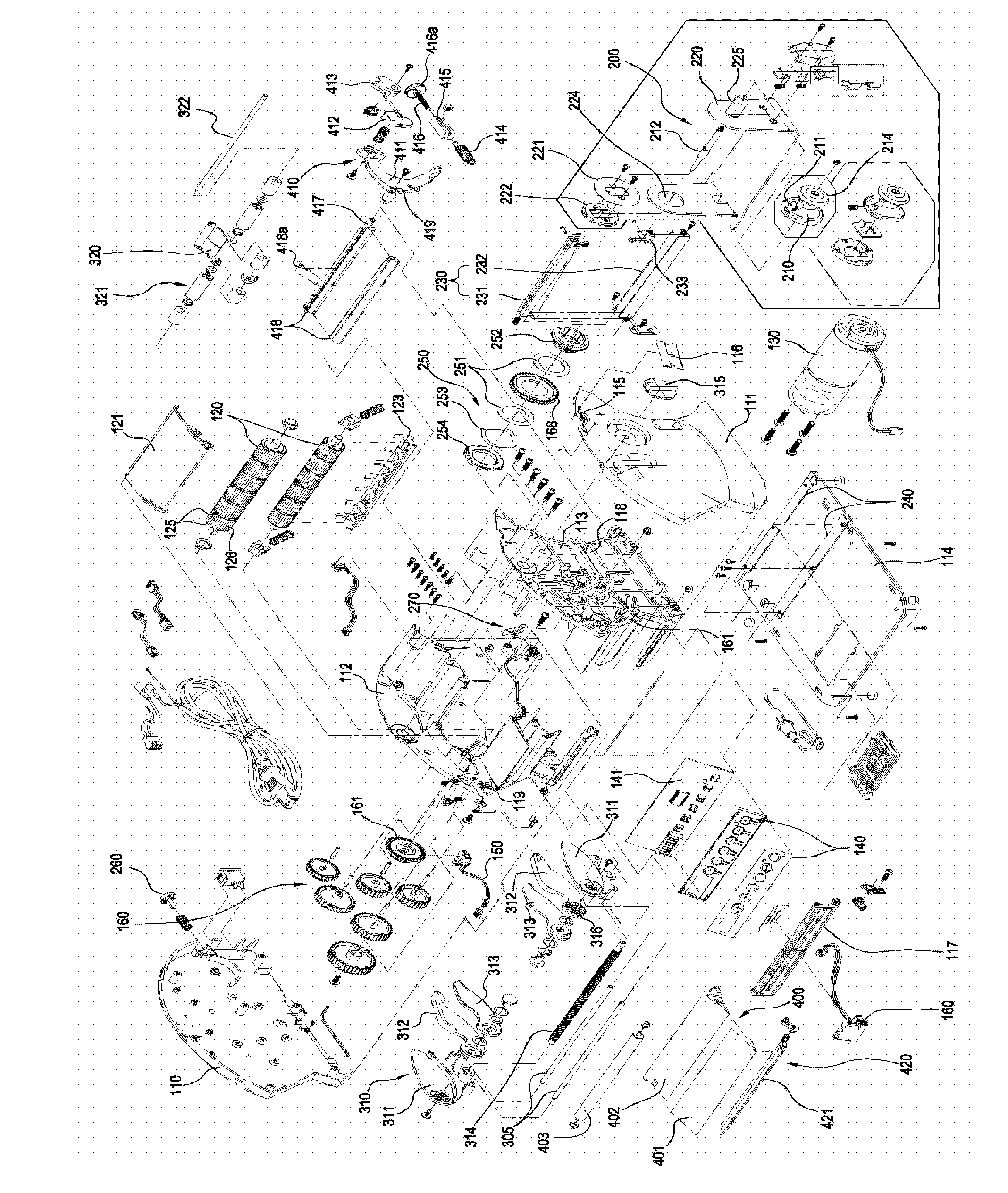

[0037] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

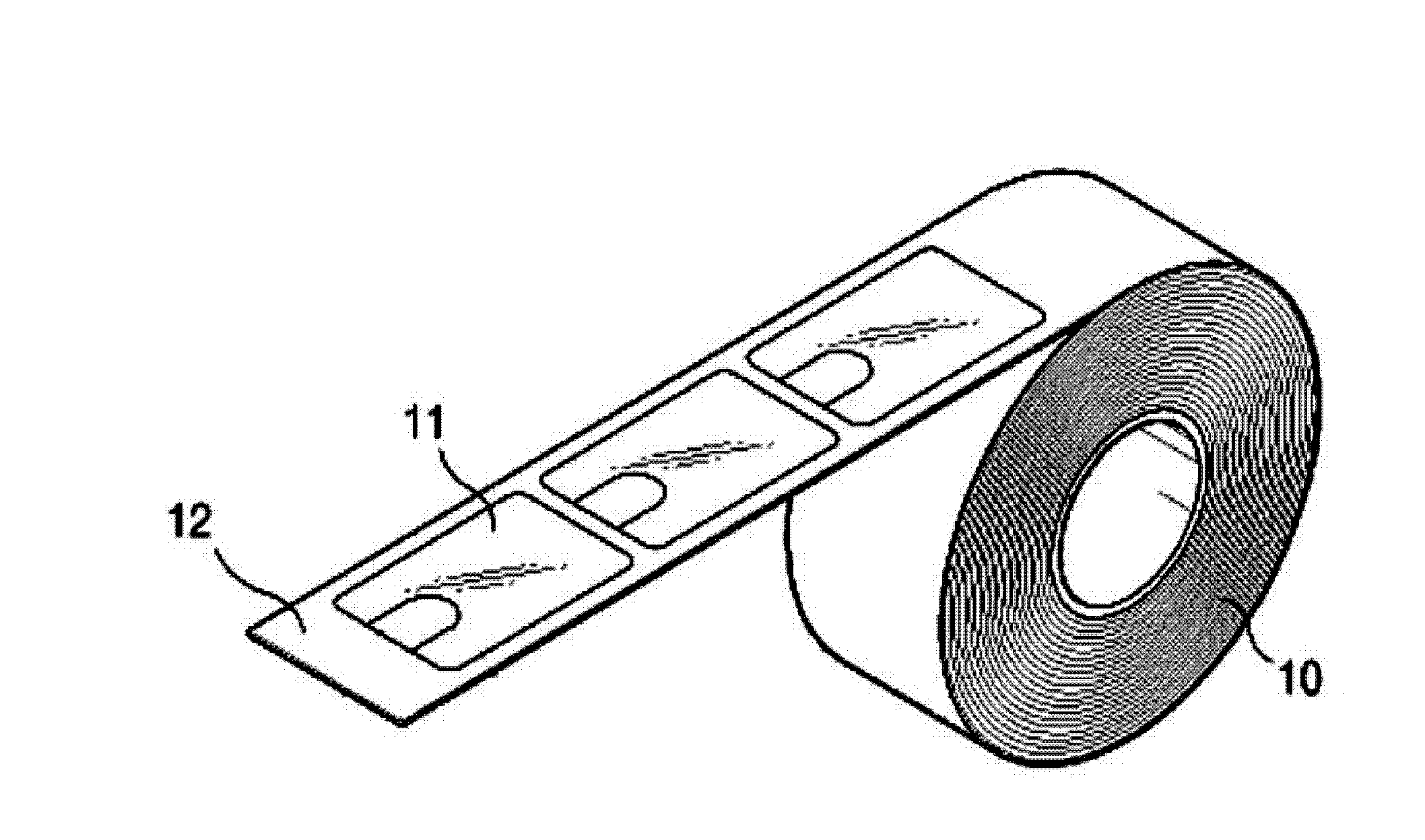

[0038] As shown in the accompanying drawings, in the automatic label separating machine of the present invention, after the roll-shaped label paper 500 with the label 501 bonded to the release paper 502 is installed on the label paper installation part 300 of the label separating machine, the motor 130 is driven to The driving force is driven to unwind the rolled label paper 500 to make it rotate, so that the label 501 is automatically separated from the release paper 502.

[0039] In the process of automatically separating the label 501 from the release paper 502 as described above, the automatic label separating machine of the present invention, in order to ensure the precision of the operation, detects position (pre-set specified position), the labels 501 are sequentially separated from the release paper 502 of the label paper 500, an...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap