Fiber short cutter roller capable of adjusting cut-in angle of cutter in stepless mode

A stepless adjustment, knife roll technology, used in fiber cutting, fiber processing, textiles and papermaking, etc., to improve the chopped effect, reduce production costs, and prolong service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

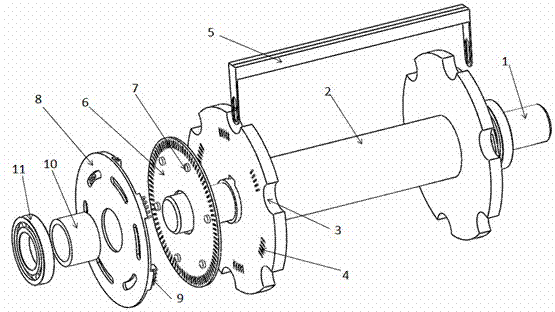

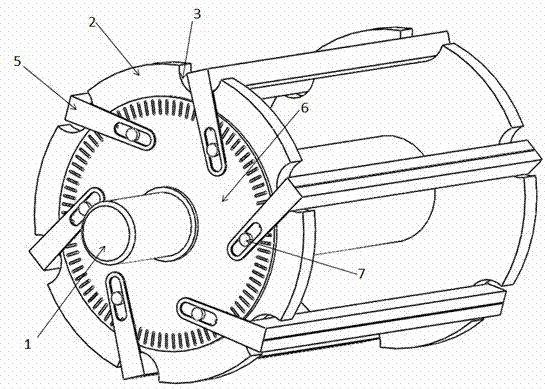

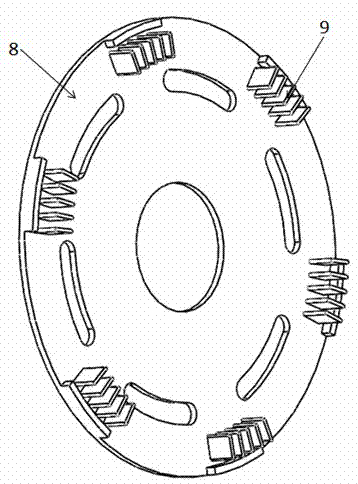

[0016] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the present invention includes an I-shaped knife roller 2, six rotating knife grooves 5 with vertical lever arms at both ends of the same structure, two angle plates 6 with the same structure, two positioning plates 8 with the same structure and a ladder Shaft 1; the I-shaped knife roller 2 is installed in the middle of the stepped shaft 1, the inner hole of the I-shaped knife roller 2 is fixedly connected with the stepped shaft 1, and the two ends of the I-shaped knife roller 2 are respectively opened with etc. There are six arc-shaped grooves 3 distributed at intervals, and six sets of card slots 4 consisting of a plurality of elongated grooves are formed equidistantly on the side of the cylindrical surface at both ends of the I-shaped knife roller 2. Angle plate 6, positioning p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com