Vibration type feed cutter

A shredder, vibrating technology, applied in the field of vibrating feed shredders, can solve the problems of poor feeding, personal injury, feed blockage, etc., to improve work efficiency, improve service life, and achieve good shredding effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

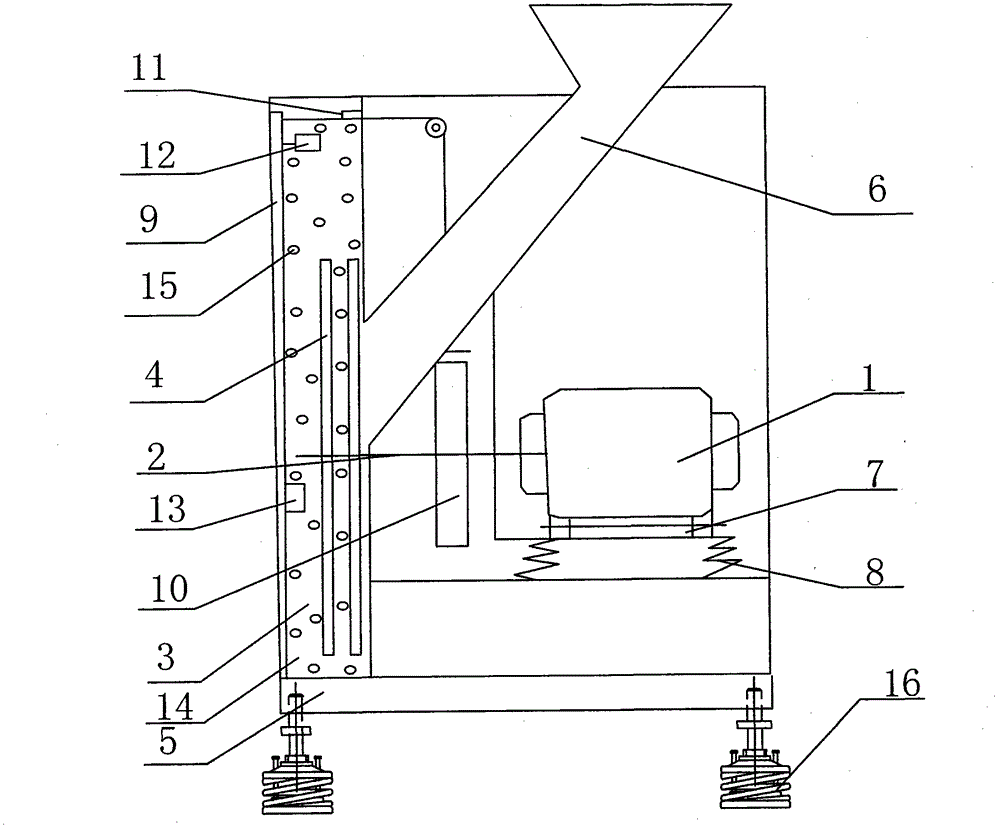

[0013] Such as figure 1 As shown, a vibrating feed shredder of the present invention comprises a motor 1, a motor shaft 2, a chopping chamber 3, a blade 4 fixed to the front end of the motor shaft 2, a safety cabinet 5, and is hinged in the safety cabinet 5 and lowered A motor base 7 connected to the feeder 6, a supporting spring 8 is provided under the motor base 7, a cabinet door 9 is provided on the safety cabinet 5, a brake 10 is installed on the motor shaft 2, and a brake 10 is installed on the safety cabinet 5. A controller 11 of a brake 10 is installed on the cabinet door 9 of 5, a circuit breaker 12 is also installed on the cabinet door 9, a temperature sensor 13 is arranged on the side wall of the chopping chamber 3, and the temperature sensor 13 is electrically connected with the circuit breaker 12, and the circuit breaker 12 is linked with the opening and closing of the cabinet door 9. A sieve plate 14 is provided under the blade 4, and sieve holes 15 are evenly dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com