Rice and wheat field secondary harvesting baler

A technology for balers and combine harvesters, which is applied in the direction of balers, harvesters, cutters, etc., can solve the problems of polluting the environment, waste of resources, manual cleaning, etc., and achieves a simple production process, light structure, and convenient packaging. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

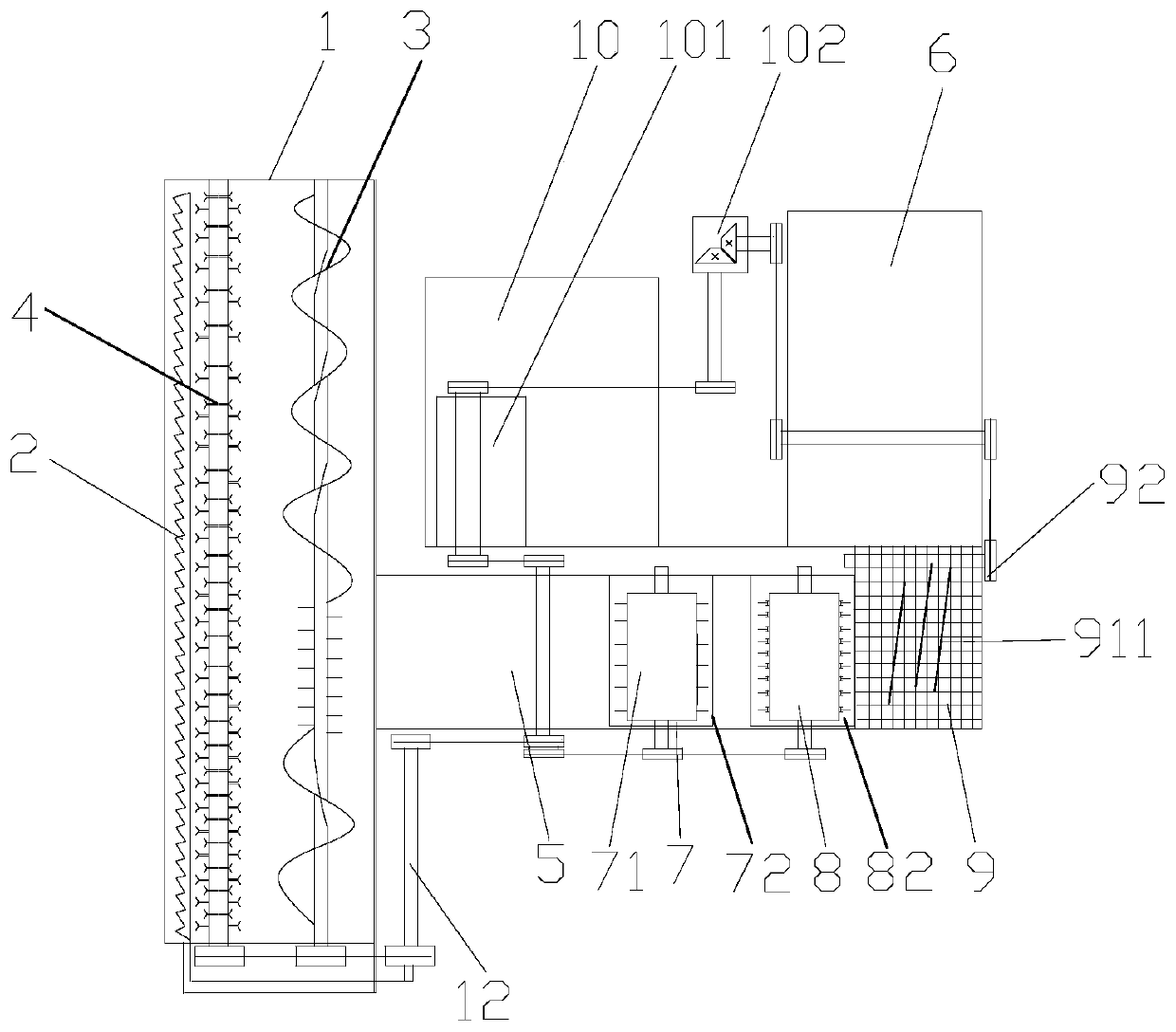

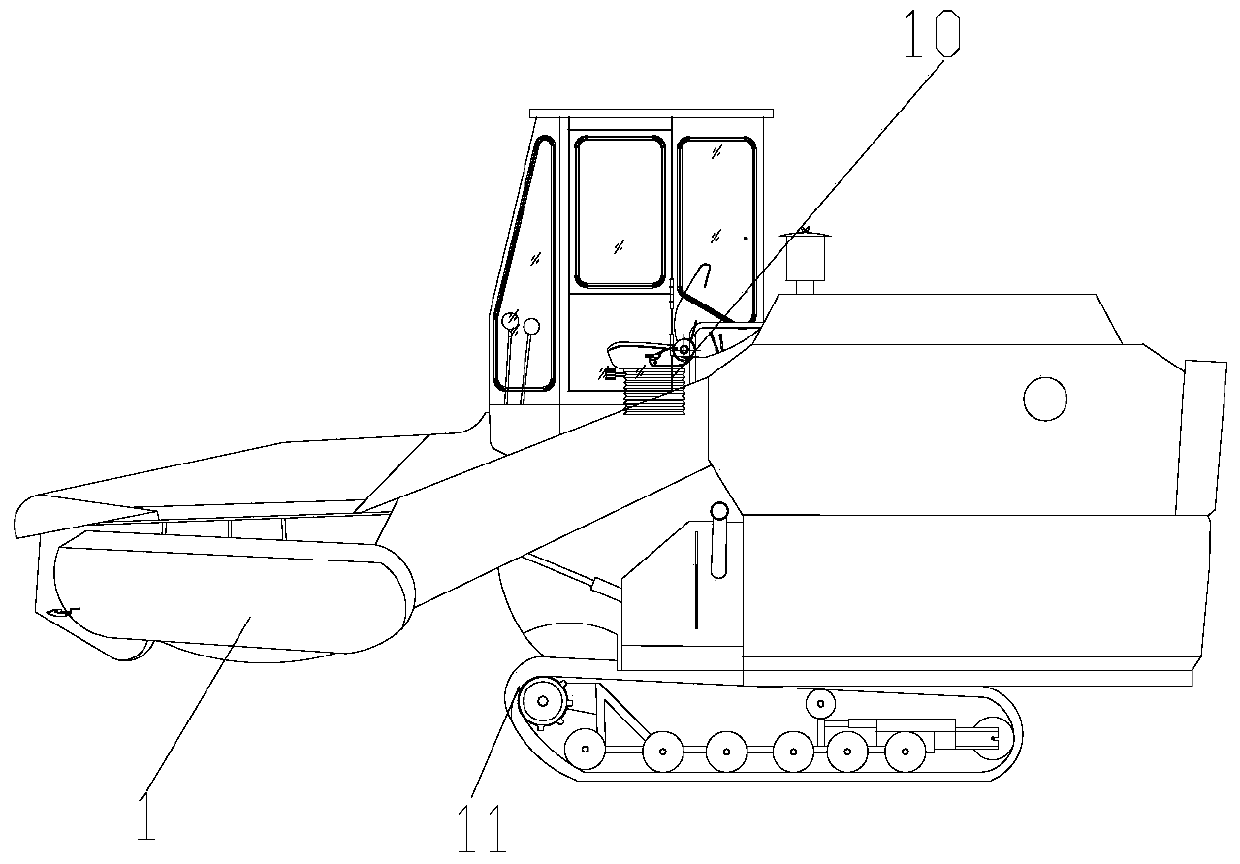

[0052] Combine below Figure 1 to Figure 22 The structure and principle of the present invention are described in detail:

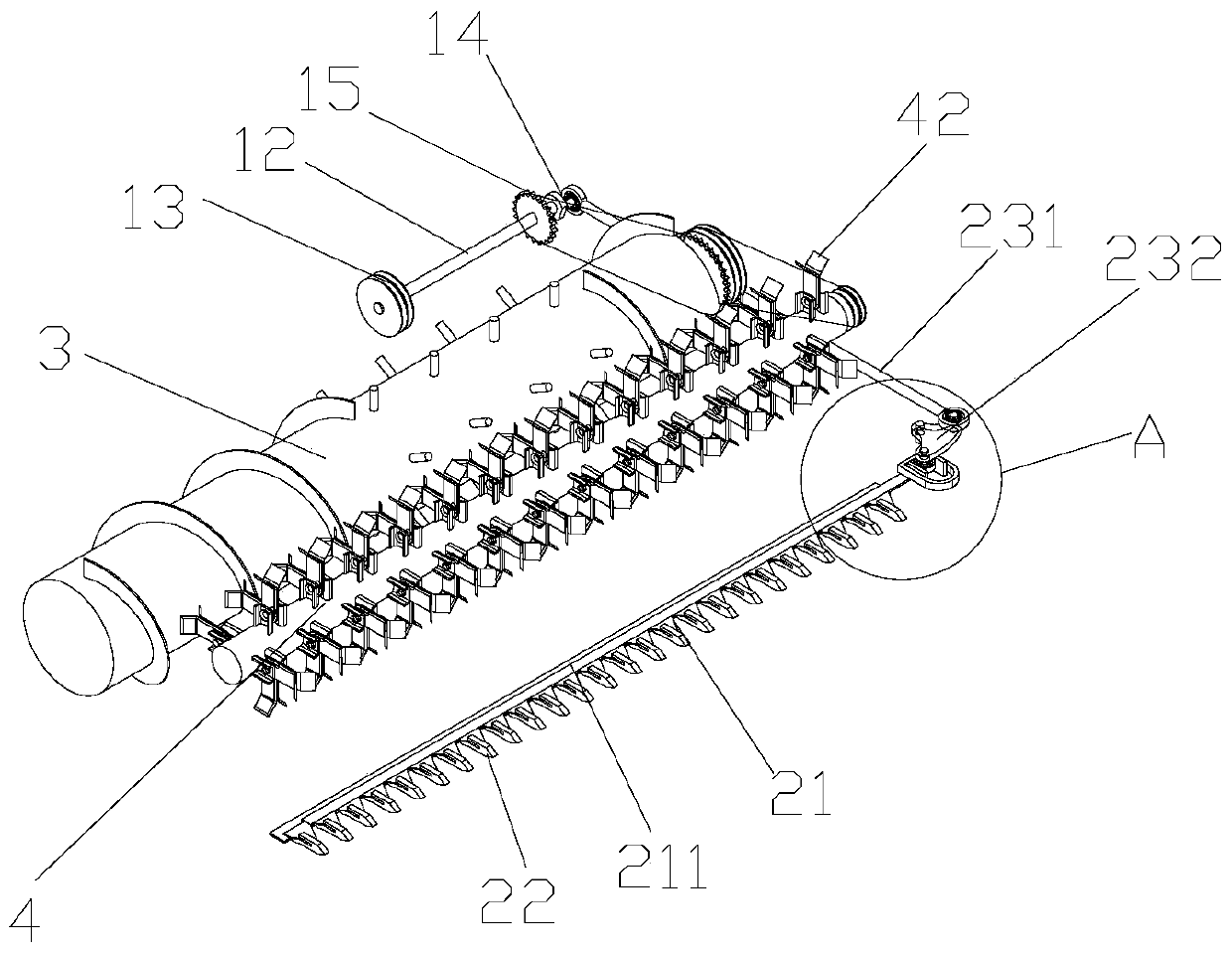

[0053] like figure 1 and figure 2 As shown, the specific embodiment of the present invention comprises combine harvester, is provided with header 1 at the front end of described combine harvester, is provided with cutter assembly 2 and propeller 3 on described header 1, in described A flying knife roller 4 is arranged between the cutting knife assembly 2 and the pusher 3 . A conveying device 5 is arranged behind the pusher 3 , and a strapping machine 6 is arranged at the end of the conveying device 5 . Propeller 3 is a Jiaolong formula propeller. The running device of the combine harvester is a crawler type running gear 11 .

[0054] like Figure 3-Figure 7 As shown, the flying knife drum 4 includes a drum body 41 and a flying blade 42 hingedly connected to the drum body 41, as Image 6 As shown, the flying blades 42 are Y-shaped, and a base 411 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com