A kind of production process of biomass wheat straw plate

A board production and biomass technology, applied in wood processing equipment, grain processing, flat products, etc., can solve the problems of uneven wheat straw particles, the quality of wheat straw boards, and the inability to fully crush wheat straw, etc., to achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

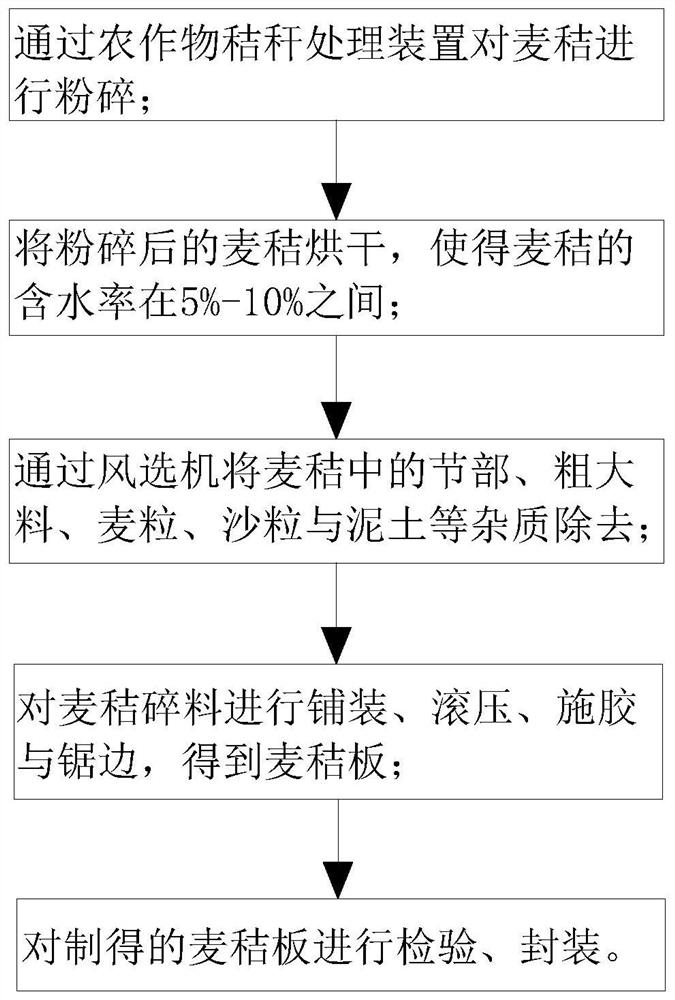

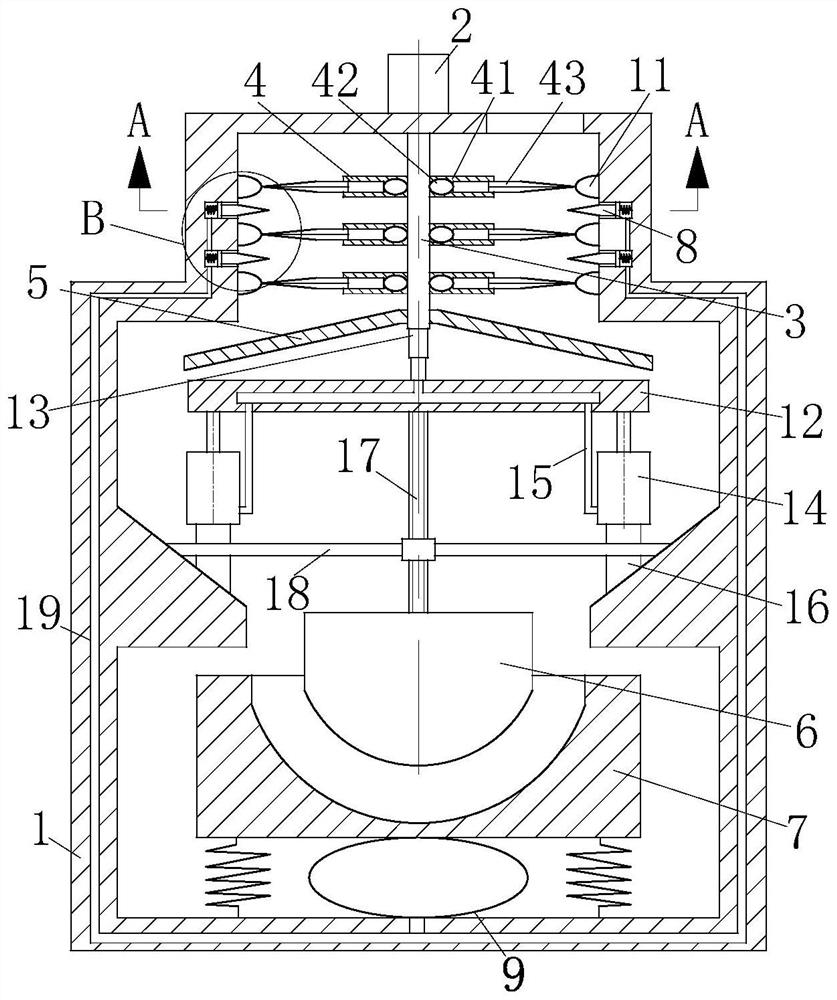

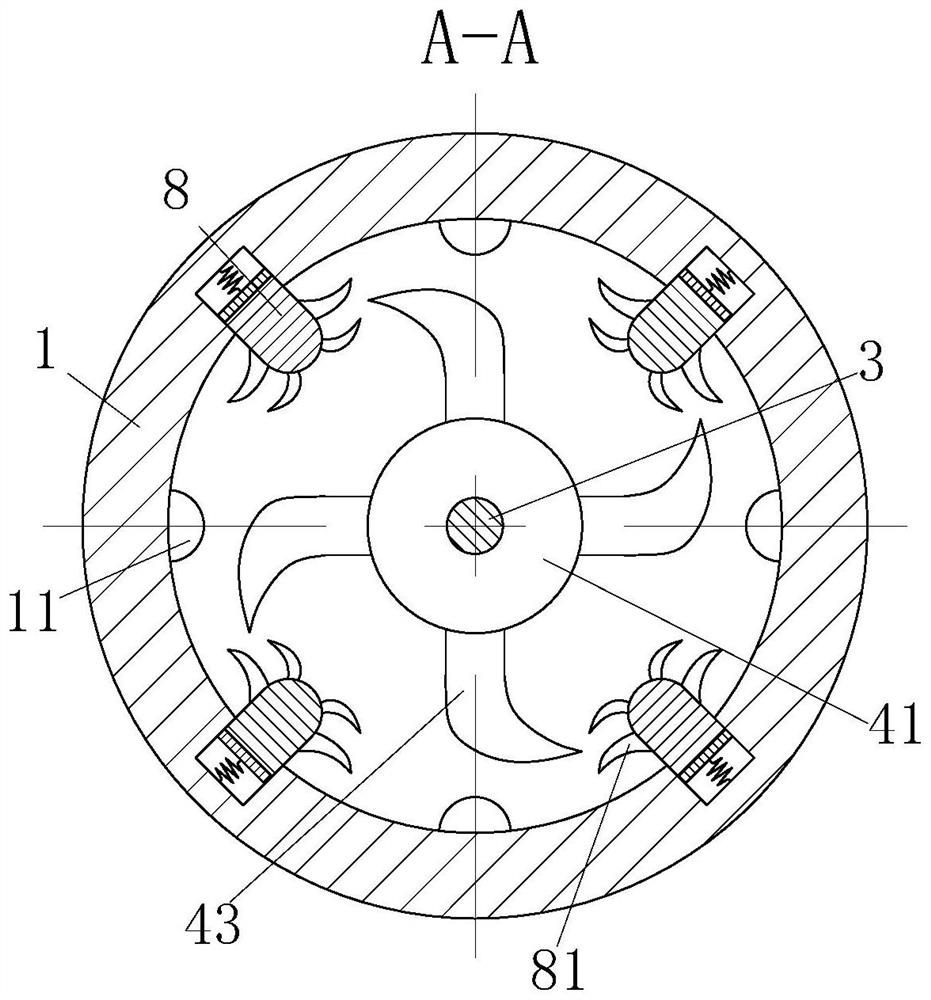

[0026] use Figure 1-Figure 4 The manufacturing process of the straw board which concerns on one embodiment of this invention is demonstrated as follows.

[0027] Such as figure 1 and figure 2 Shown, a kind of biomass wheat straw board production process of the present invention, this process comprises the steps:

[0028] Step 1: crushing the wheat straw through the crop straw processing device;

[0029] Step 2: After crushing in step 1, drying the crushed wheat straw so that the moisture content of the wheat straw is between 5% and 10%;

[0030] Step 3: after drying in step 2, remove impurities such as knots, coarse materials, wheat grains, sand grains and soil in the wheat straw by a winnowing machine;

[0031] Step 4: After winnowing in step 3, paving, rolling, sizing and sawing the wheat straw scraps to obtain wheat straw boards;

[0032] Step 5: After obtaining the wheat straw board, inspect and package the prepared wheat straw board;

[0033] Wherein, the crop sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com