Safety type repairable and replaceable louver blade component

A technology for repairing and replacing louvers, which is applied to building components, door/window protection devices, shading screens, etc. It can solve problems such as inability to repair and replace, safety hazards, and easy to fall off, and achieves convenient installation, rapid maintenance and replacement, and wide application range wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

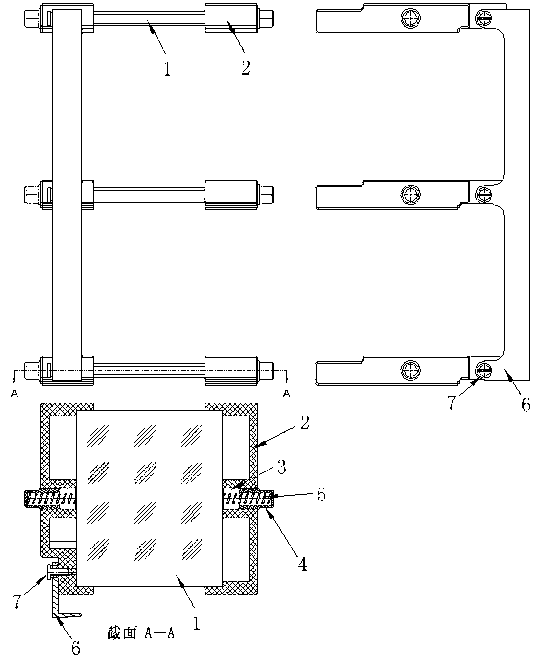

[0035] Example 1: figure 1 , Figure 4 , Figure 5 , Image 6 , Figure 9 , Figure 10 , Figure 11 , Figure 12 A diagram of this example is given. see figure 1 , Figure 4 , Figure 5 , Image 6 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , the present invention includes louver blade 1, blade cover 2, shaft hole 3, shaft 4, spring 5, connecting rod 6, screw 7 and shaft sleeve 9. Both ends of the louver 1 are provided with a blade cover 2, the blade cover 2 is provided with a shaft hole 3, and the shaft hole 3 is provided with a shaft 4, and the shaft 4 extends out of one end of the blade cover, and a spring 5 is provided between the shaft 4 and the shaft hole 3 , the rotating shaft 4 can be elastically pressed into the rotating shaft hole 3 of the blade cover 2, and the rotating shaft 4 in the blade cover 2 can pop out and extend under the action of the spring 5 when it is aligned with the rotating shaft hole on the frame of the louver door, louver, or ...

Embodiment 2

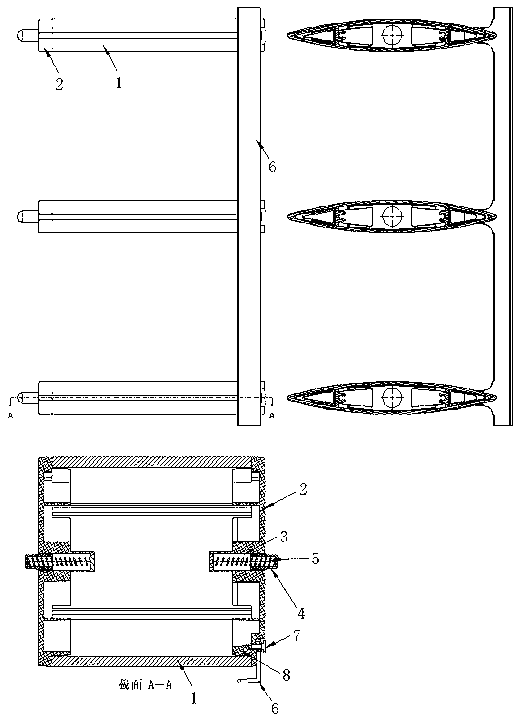

[0044] Example 2: figure 2 , Figure 7 , Figure 8 A diagram of this example is given. see figure 2 , Figure 7 , Figure 8 , the present invention includes a louver blade 1, a blade cover 2, a shaft hole 3, a shaft 4, a spring 5, a connecting rod 6, a screw 7, and a thin-walled step 8. Embodiment 2 is basically the same as Embodiment 1, except that the material of the louvers 1 in this embodiment is a thin-walled material, and a thin-walled step 8 is provided on the inner side of the blade cover 2 for clamping the louvers. The blade cover 2 can be provided with screws between the blade cover 2 and the louvers 1 .

Embodiment 3

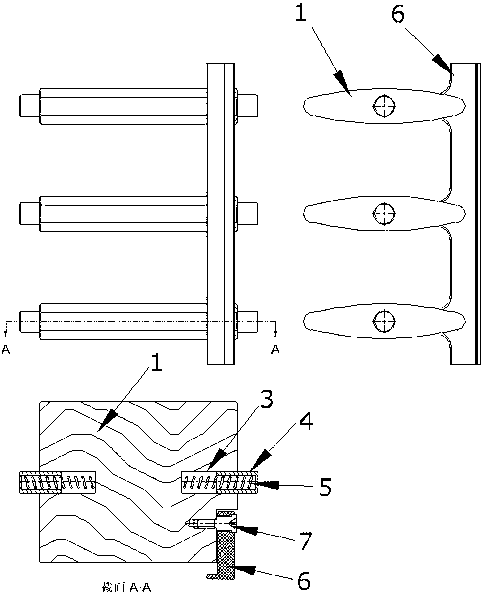

[0045] Example 3: image 3 , Figure 13 , Figure 14 , Figure 15 A diagram of this example is given. see image 3 , Figure 13 , Figure 14 , Figure 15 , the present invention includes a louver 1, a shaft hole 3, a shaft 4, a spring 5, a connecting rod 6, a screw 7, and a thin-walled step 8. Embodiment 3 is basically the same as Embodiment 1, except that the material of the louver 1 in this embodiment is solid wood or other solid materials, the blade cover 2 is omitted, and the shaft holes 3 and corresponding Rotating shaft 4 and spring 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com