Symmetric Y-shaped steel branch pipe

A steel branch pipe, symmetrical technology, applied in the direction of pipes, branch pipelines, pipes/pipe joints/pipe fittings, etc., can solve the problems of self-flowing drainage, inconvenient transportation, pipe bottom height difference, etc., and achieve self-flowing drainage and convenient transportation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

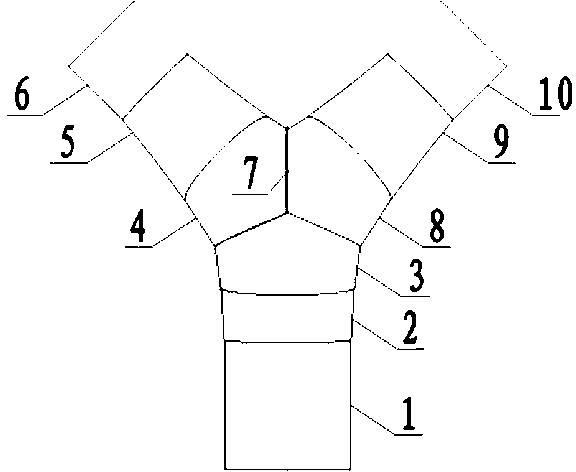

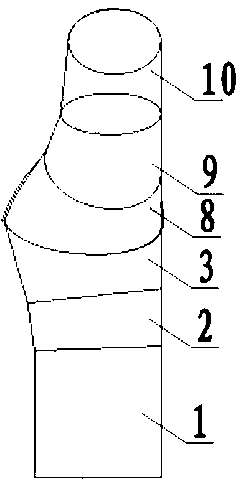

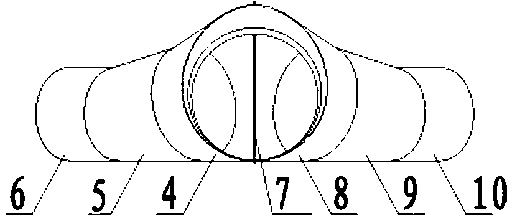

[0010] Such as figure 1 , 2 , 3, the symmetrical Y-shaped steel bifurcated pipe of the present invention comprises a main pipe straight pipe section 1, a main pipe transition section 2, a main tapered pipe section 3, a left branch tapered pipe section 4, a left branch pipe transition section 5, and a left branch straight pipe section 6 , crescent rib 7, right branch cone pipe section 8, right branch pipe transition section 9, right branch pipe straight pipe section 10; said main pipe straight pipe section 1, left branch straight pipe section 6, and right branch straight pipe section 10 use conventional circular pressure steel pipes, crescent rib 7. The crescent-shaped steel plate is cut from the steel plate, and the rest of the pipe sections are conical pipes rolled and welded by the steel plate.

[0011] The straight pipe section 1 of the main pipe connects with the main tapered pipe 3 through the main pipe transition section 2, and the main tapered pipe 3 respectively conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com