A palletizer with wide application range and high palletizing efficiency

A technology with high scope of application and high efficiency, applied in the field of palletizers, can solve the problems of low material handling capacity, inaccurate manual placement of materials, time-consuming and labor-intensive, etc. The effect of improving the efficiency of material palletizing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited in any way. Any transformation or replacement based on the teaching of the present invention belongs to the protection scope of the present invention.

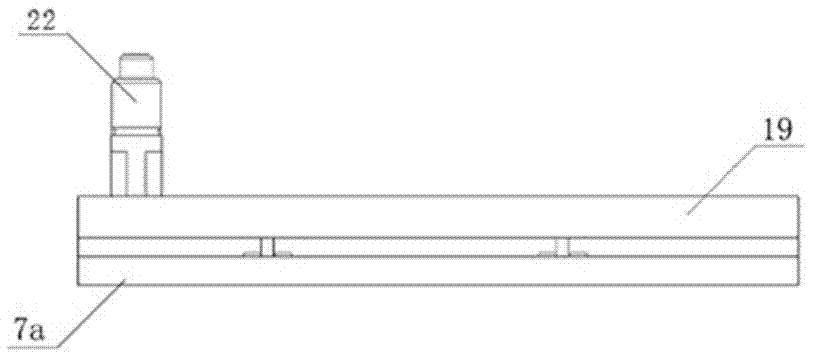

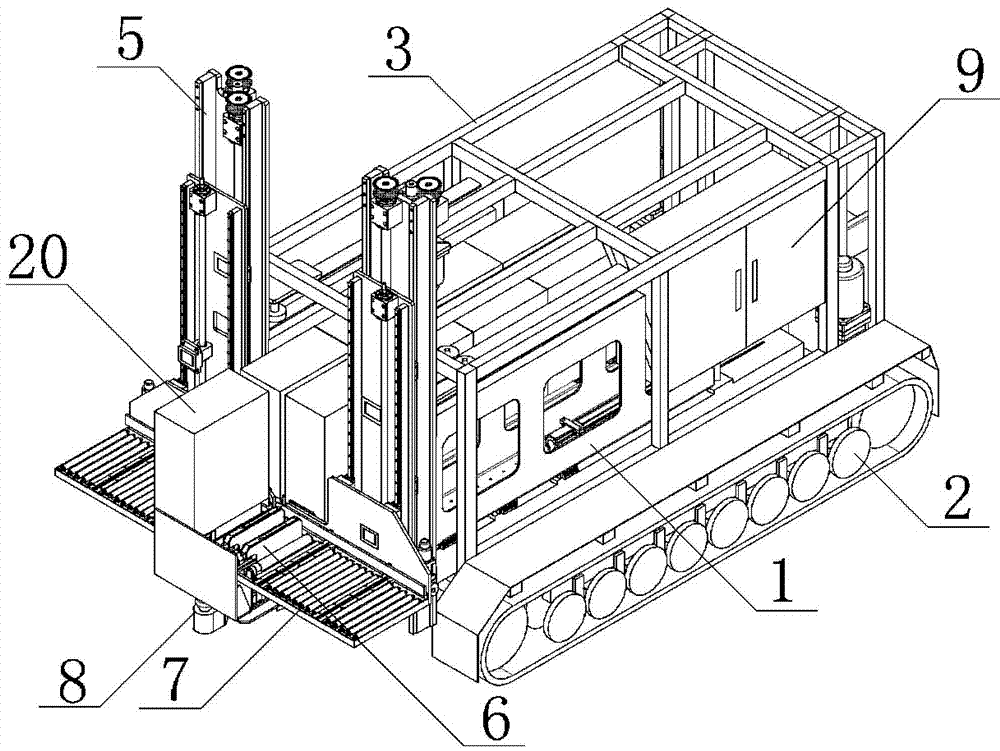

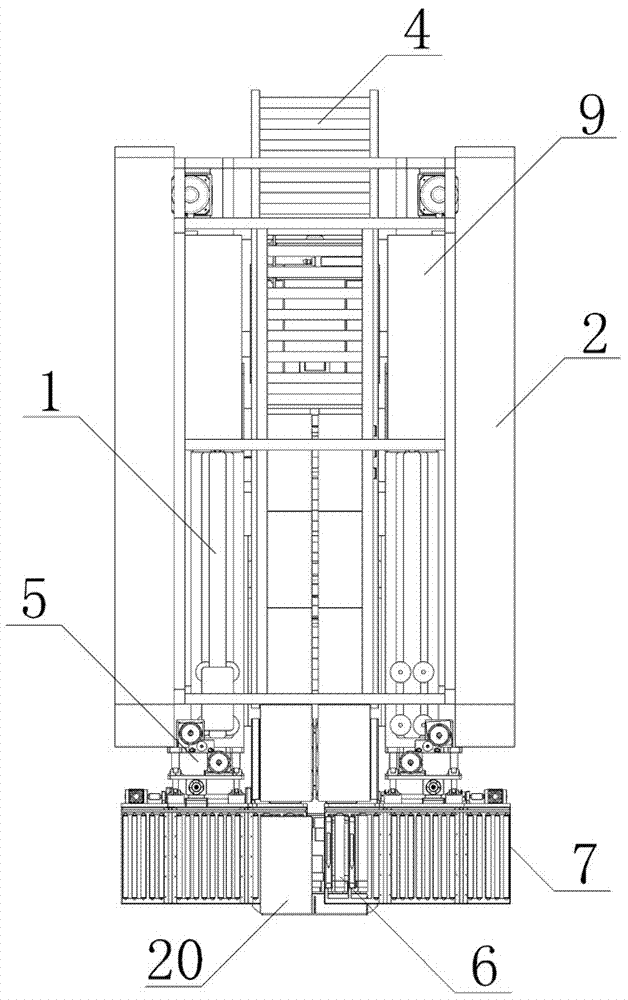

[0040] as attached Figure 1~Figure 25 The present invention shown includes a base, a multi-stage telescopic transfer mechanism 1, a running mechanism 2, a frame support 3, a finishing mechanism 4, a multi-stage lifting transfer mechanism 5, a flow diversion mechanism 6, a push mechanism 7, a positioning device 8, a control Device 9, the walking mechanism 2 is arranged on both sides of the base, the frame-shaped support 3 is arranged on the base, the multi-stage telescopic transfer mechanism 1 is arranged on the base in the frame-shaped support 3, the The above-mentioned finishing mechanism 4 is arranged on the multi-stage telescopic transfer mechanism 1, the described multi-stage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com