Method for adjusting the flatness of the large bottom plate of the tower body

An adjustment method and flatness technology, applied to cranes and other directions, can solve the problems of high production cost, uneven tower body and large bottom plate, low efficiency, etc., and achieve the effects of reducing production cycle, improving low efficiency and saving production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

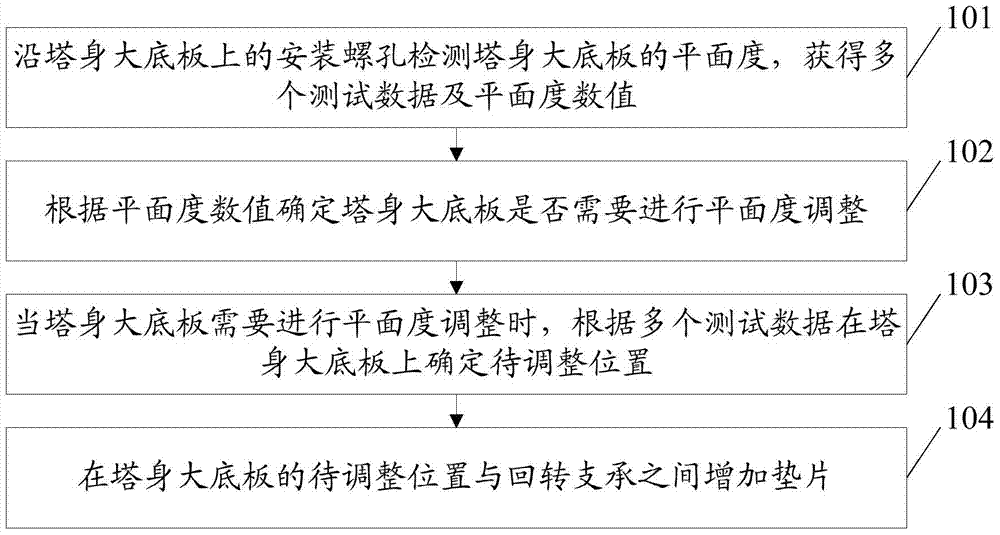

[0043] figure 1 It is a flow chart of a method for adjusting the flatness of the large bottom plate of the tower body provided by the embodiment of the present invention, see figure 1 , the method includes:

[0044] Step 101: Detect the flatness of the large base plate of the tower body along the mounting screw holes on the large base plate of the tower body, and obtain multiple test data and flatness values. The test data is the distance between the detection position and the set plane, and the flatness value is based on multiple calculated from test data.

[0045] Wherein, the setting plane is defined by a testing tool, such as a virtual plane in a flatness tester.

[0046] Optionally, the flatness of the large tower base plate is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com