Light emitting diode (LED) spherical lamp transmitting heat through liquid

An LED spherical lamp, liquid technology, applied in lighting and heating equipment, semiconductor devices of light-emitting elements, cooling/heating devices of lighting devices, etc. The heat dissipation structure is simple and compact, the production cost is reduced, and the heat dissipation effect is excellent.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

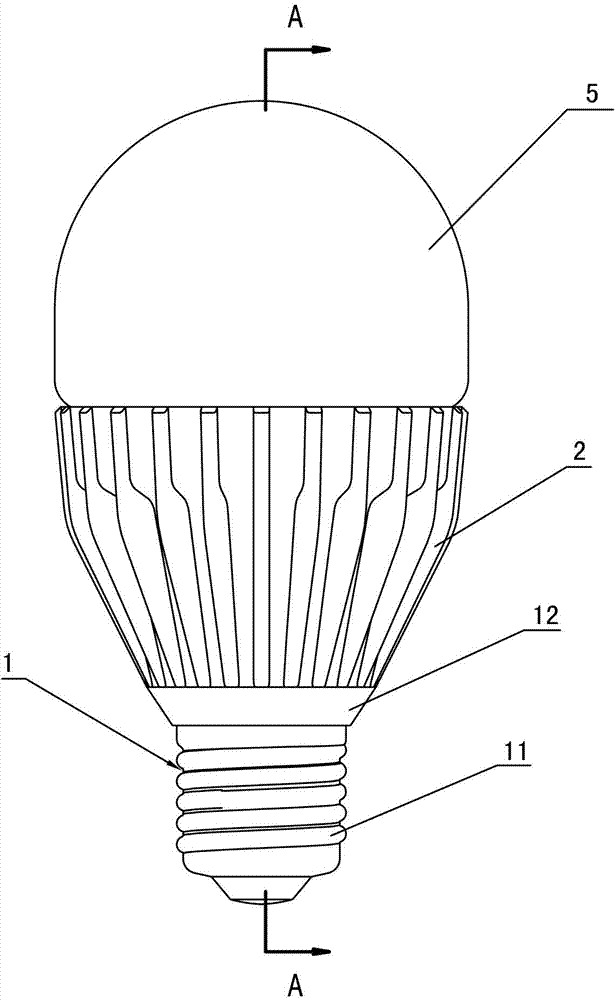

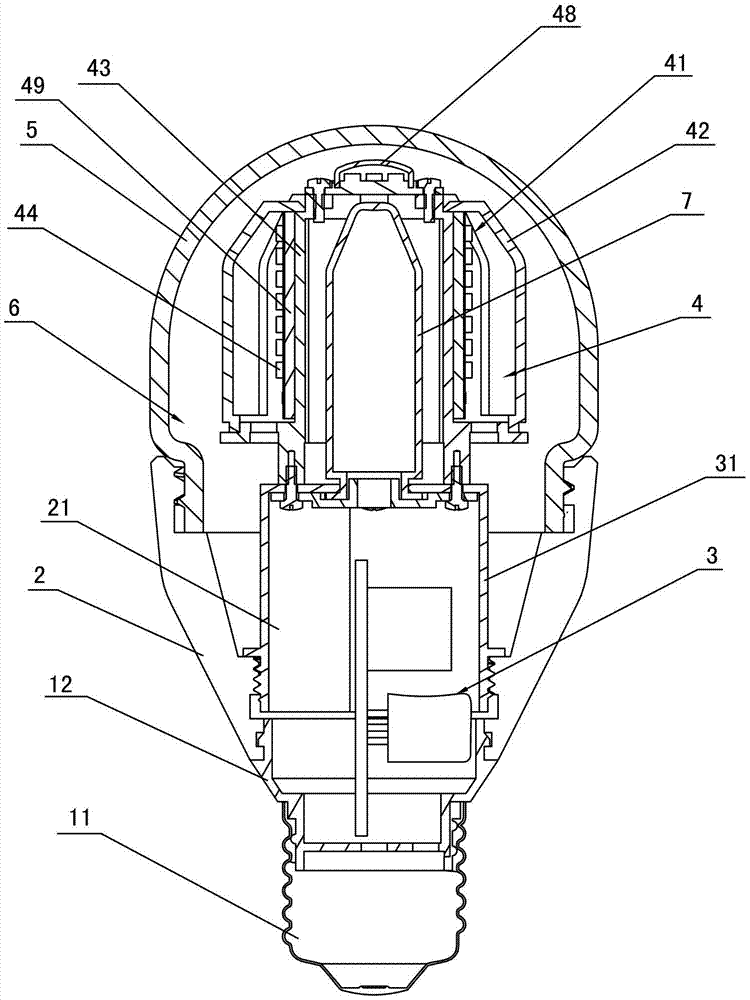

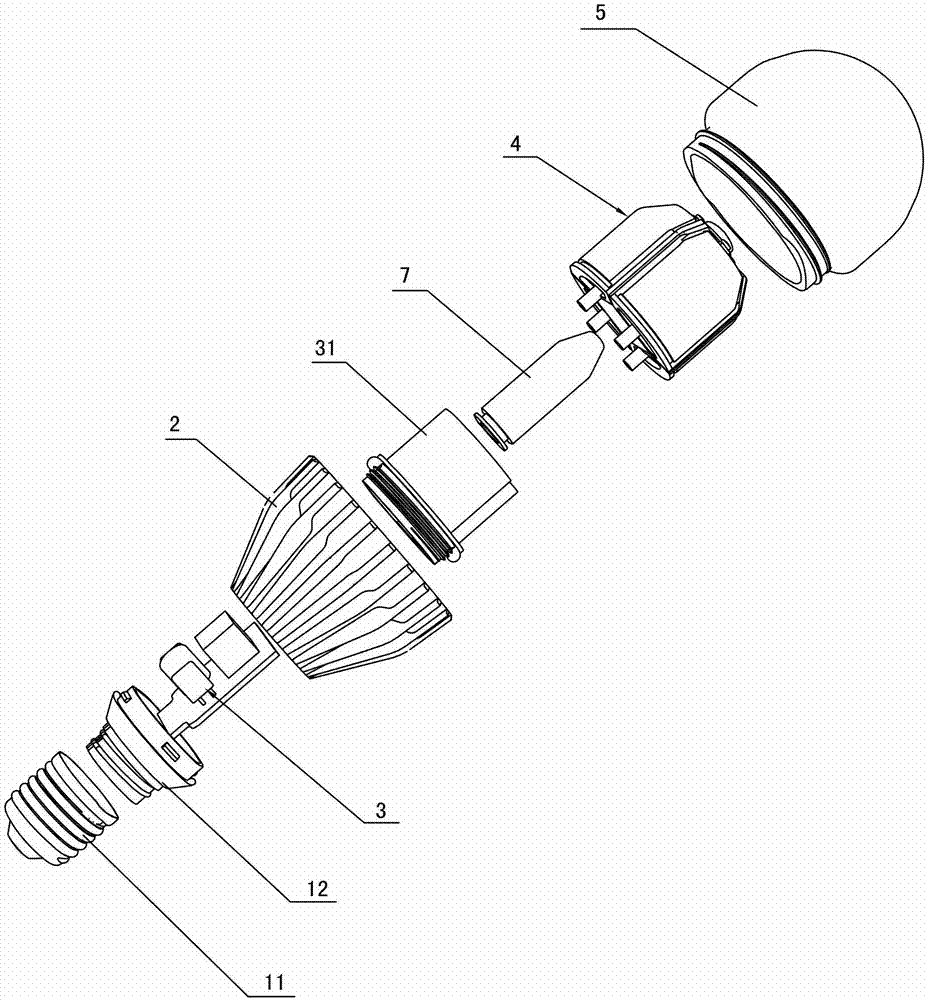

[0027] A liquid heat transfer LED spherical lamp proposed by the present invention, such as figure 1 , figure 2 and image 3 As shown, it includes a lamp cap assembly 1, a hollow radiator 2, a driving power supply 3, a light emitting assembly 4 and a glass cover 5. The lamp cap assembly 1 is mainly composed of a lamp cap 11 and a lamp cap connecting seat 12 connected with the lamp cap 11. The light emitting assembly 4 Located in the glass cover 5, the hollow radiator 2 is provided with a power supply chamber 21, the rear end edge of the hollow radiator 2 is connected to the front edge of the lamp holder 12, the front edge of the hollow radiator 2 is connected to the glass cover 5 The bottom edge of the cover is connected, the driving power 3 is fixed on the lamp cap connecting seat 12 and is electrically connected with the lamp cap 11, the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap