Automatic zero-setting method in vibration frequency measurement

A technology of automatic zero adjustment and vibration frequency, applied in measuring devices, measuring ultrasonic/sonic/infrasonic waves, instruments, etc., it can solve the problems of measurement error and other problems, and achieve the effect of accurate zero adjustment and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with accompanying drawing.

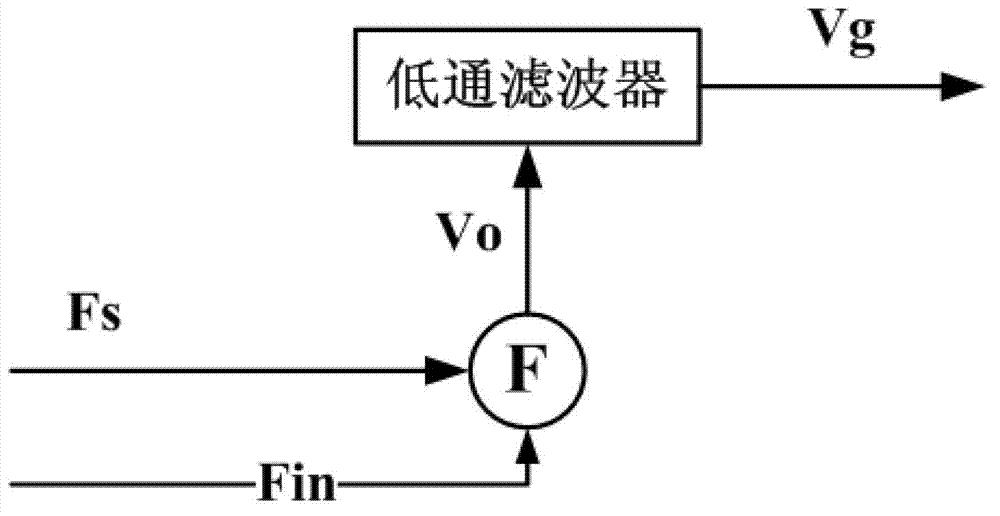

[0011] see figure 1 , the figure shows an automatic zeroing method for vibration frequency measurement, including input frequency Fin, reference frequency Fs, phase detector F, phase detector output signal Vo, low-pass filter and low-pass output DC signal vg, where :

[0012] The input frequency Fin and the reference frequency Fs are connected to the input terminal of the phase detector F, the phase detector output signal Vo is connected to the input of the low-pass filter, and the low-pass output DC signal Vg is output after low-pass filtering.

[0013] The phase detector F is an XOR logic phase detector, and the phase detector output signal Vo=Fs-Fin is a pulse signal. The low-pass output DC signal vg=(Fs-Fin)×K of the low-pass filter can adjust the voltage-controlled oscillation level and automatically generate zero-adjustment voltage.

[0014] The present invention h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com