A warp tension signal amplification conditioning circuit of a high-speed loom

A signal amplification and conditioning circuit technology, which is applied to the layout of amplifier protection circuits, looms, differential amplifiers, etc., can solve problems such as poor anti-interference ability, signal noise interference, and low signal-to-noise ratio, and achieve improved accuracy and low input Effects of Noise and Low Power Consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical solutions and advantages of the present invention clearer, specific embodiments of the present invention will be given below in conjunction with the accompanying drawings. The specific embodiments are only used to further describe the present invention in detail, and do not limit the protection scope of the present application.

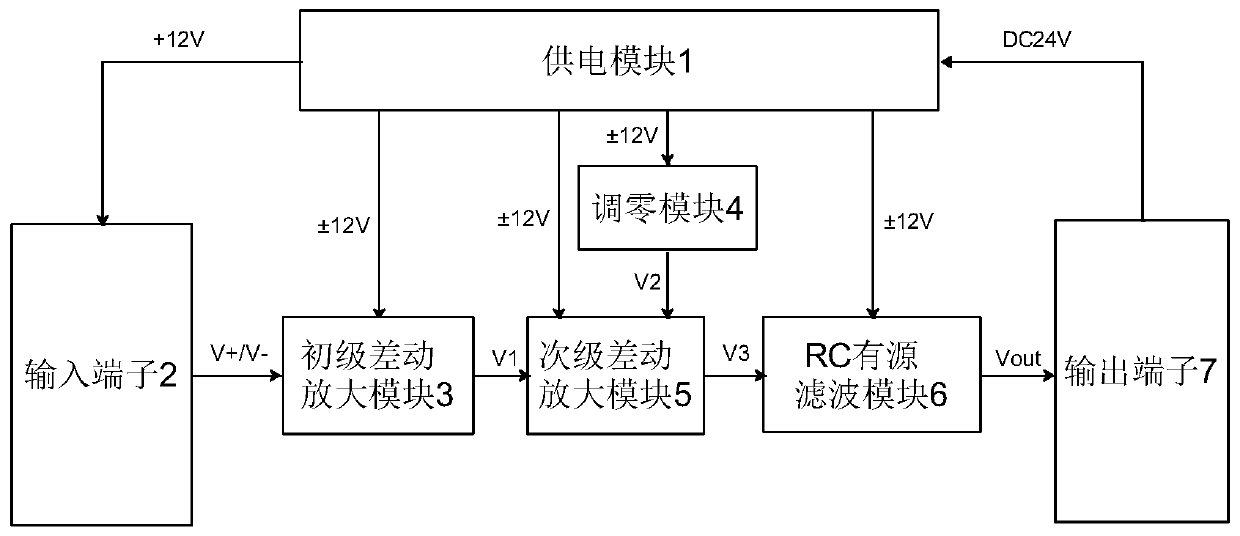

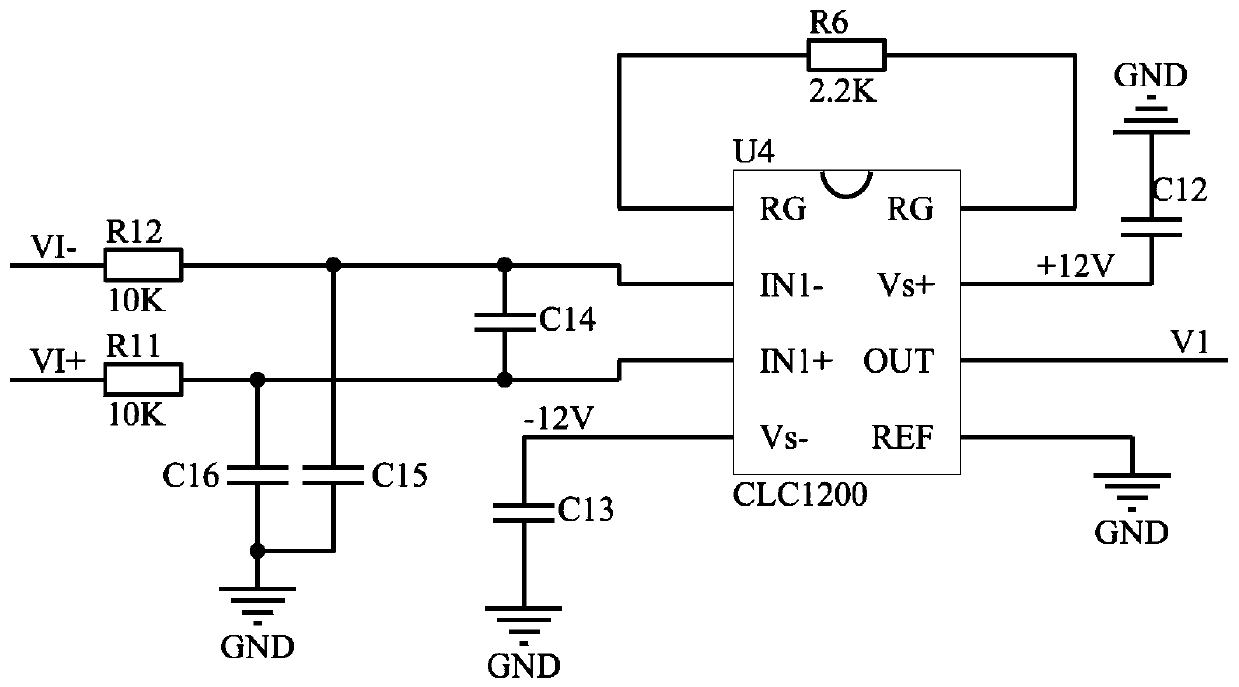

[0019] The high-speed loom warp tension signal amplification and conditioning circuit of the present invention, the signal amplification conditioning circuit includes a power supply module 1, an input terminal 2, a primary differential amplification module 3, a zero adjustment module 4, a secondary differential amplification module 5, and an RC active filter Module 6 and output terminal 7;

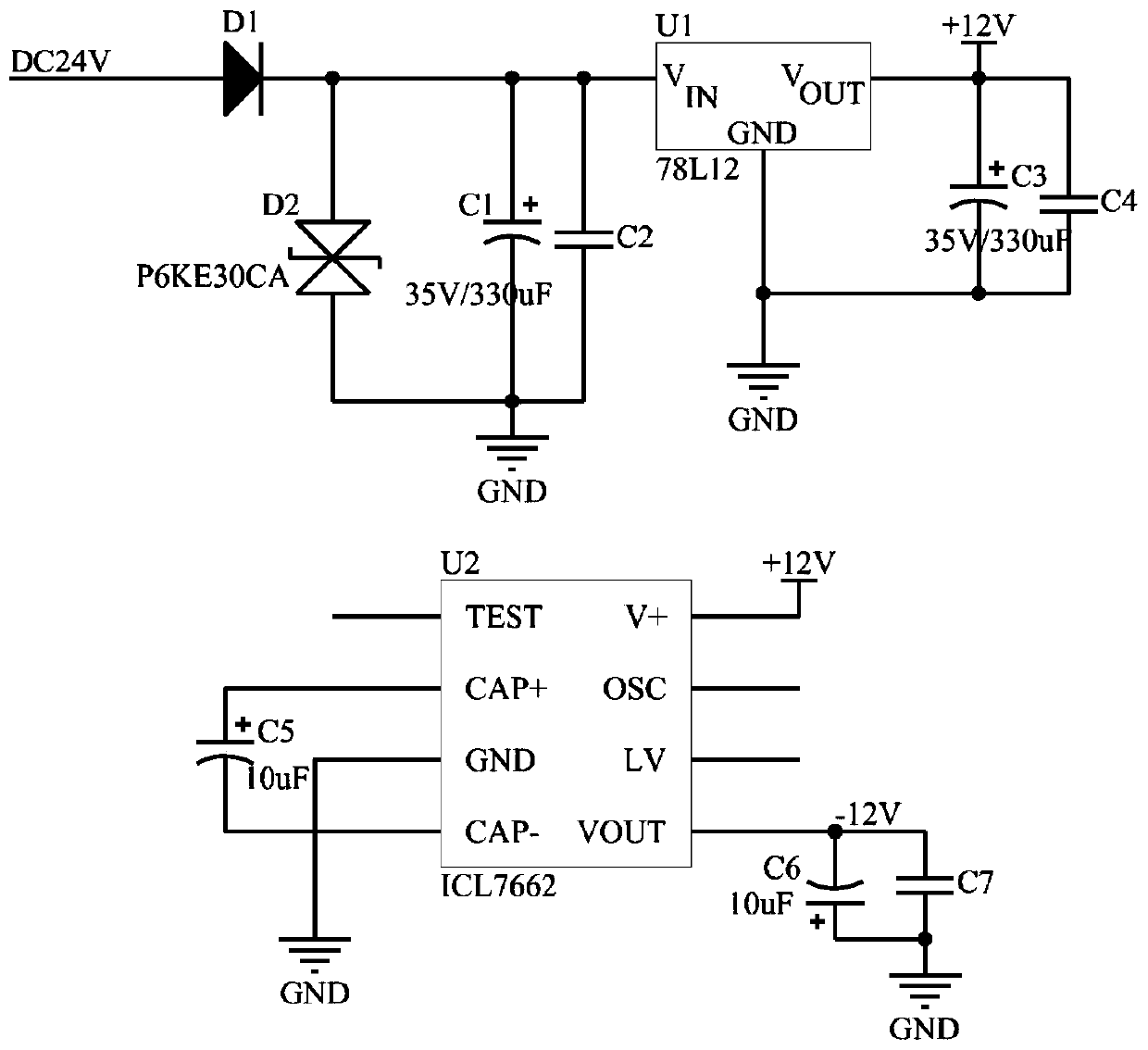

[0020] The above-mentioned output terminal 7 has four pins, which are DC power supply interface DC24V and GND, 0-5V signal output port Vo and shielding wire interface Shield signal; power supply module 1 is powered by DC24V an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com