Rapid center control testing method of Xingnaojing injection

A technology of Xingnaojing injection and detection method, which is applied in the field of near-infrared detection, can solve problems such as no relevant reports, and achieve the effects of stable product quality and improved quality control level.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] (1) Distillate sample collection

[0060] Collection of distillate samples during the primary distillation of different batches of medicinal materials

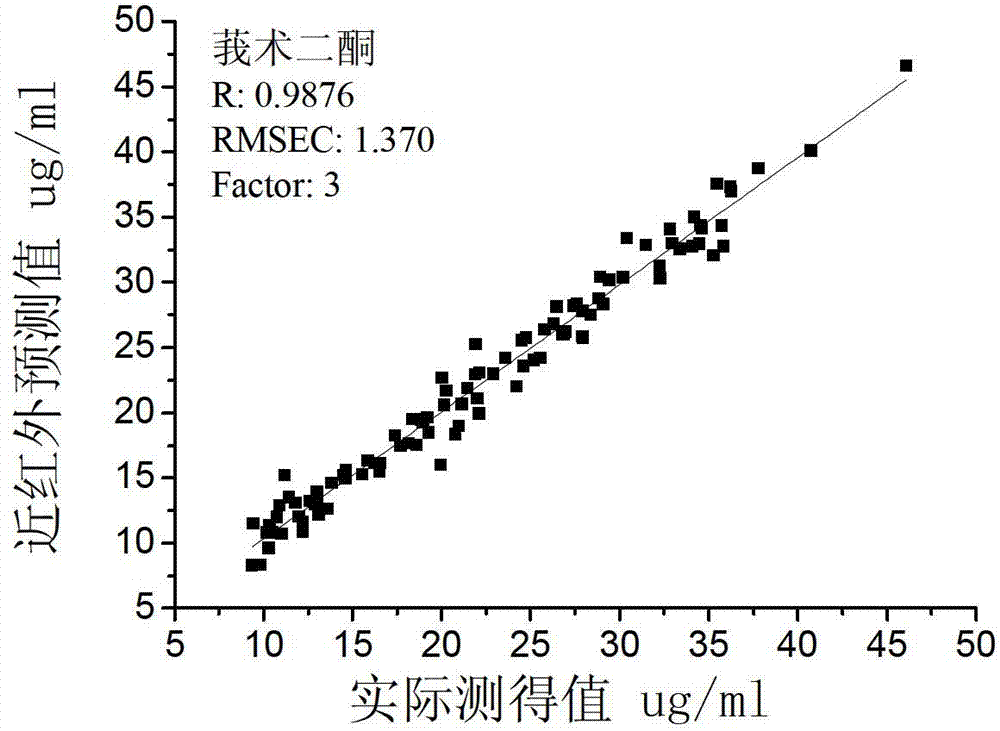

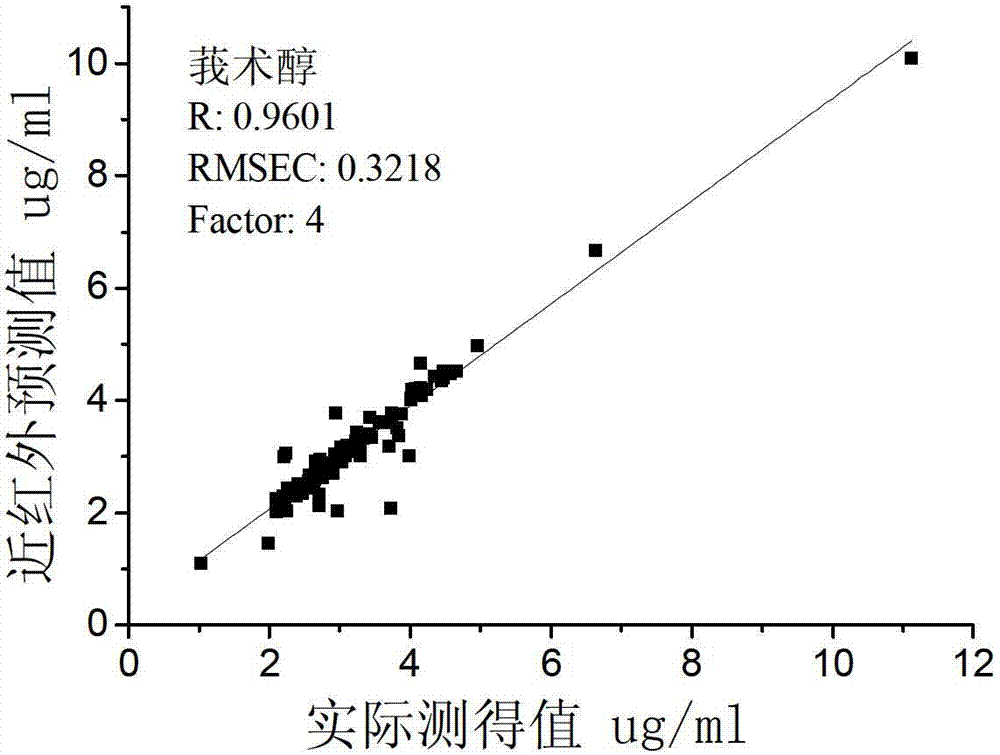

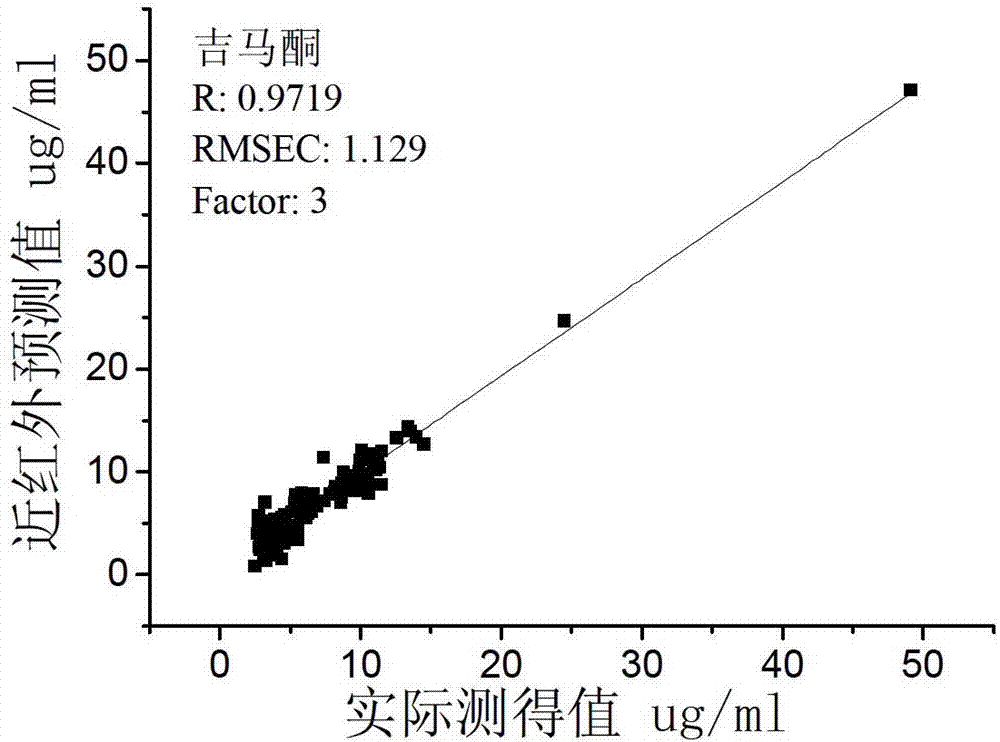

[0061] One distillation process: turmeric and gardenia medicinal materials, add 25 times the amount of distilled water for distillation. After reaching the distillation temperature (keep warm, about one hour after the start of temperature rise), start to collect distillate samples, and the time interval of sample collection is 1 hour. The samples taken were used for the determination of curdione, curcumol, gemaconone and the total peak area of the liquid phase respectively. The distillation extraction experiment of 6 batches of turmeric and gardenia medicinal materials was repeated, and samples were taken in the same way for each batch of experiments, and a total of 120 primary distillate samples were obtained.

[0062] (2) Determination of key indicators

[0063] Sample pretreatment method: Take 10ml of the distil...

Embodiment 2

[0078] According to the method of Example 1, the difference lies in the establishment of a rapid analysis model for each key index in the secondary distillation process.

[0079] (1) Collect distillate samples from different batches of medicinal materials during secondary distillation

[0080] Secondary distillation process: Take the primary distillate and add musk and appropriate amount of distilled water for distillation. After reaching the distillation temperature (keep warm, about one hour after the start of temperature rise), start to collect distillate samples, and the time interval of sample collection is 1 hour. The samples taken were used for the determination of curdione, curcumol, gemacone, muscone and the total peak area of the liquid phase respectively. Six batches of secondary distillation experiments were repeated, and samples were taken in the same way for each batch of experiments. A total of 120 secondary distillation samples were obtained for establishing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com