A Partial Discharge Simulation Device for Metal Enclosed Combined Electric Appliances

A metal-enclosed, partial discharge technology, applied in the direction of testing dielectric strength, test ship construction, etc., can solve the problems of affecting signal characteristic analysis, poor discharge controllability, large difference, etc., to achieve convenient gas chamber capacity, gas chamber capacity Moderate, avoid shell explosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to better understand the technical content of the present invention, specific embodiments are given together with the attached drawings for description as follows.

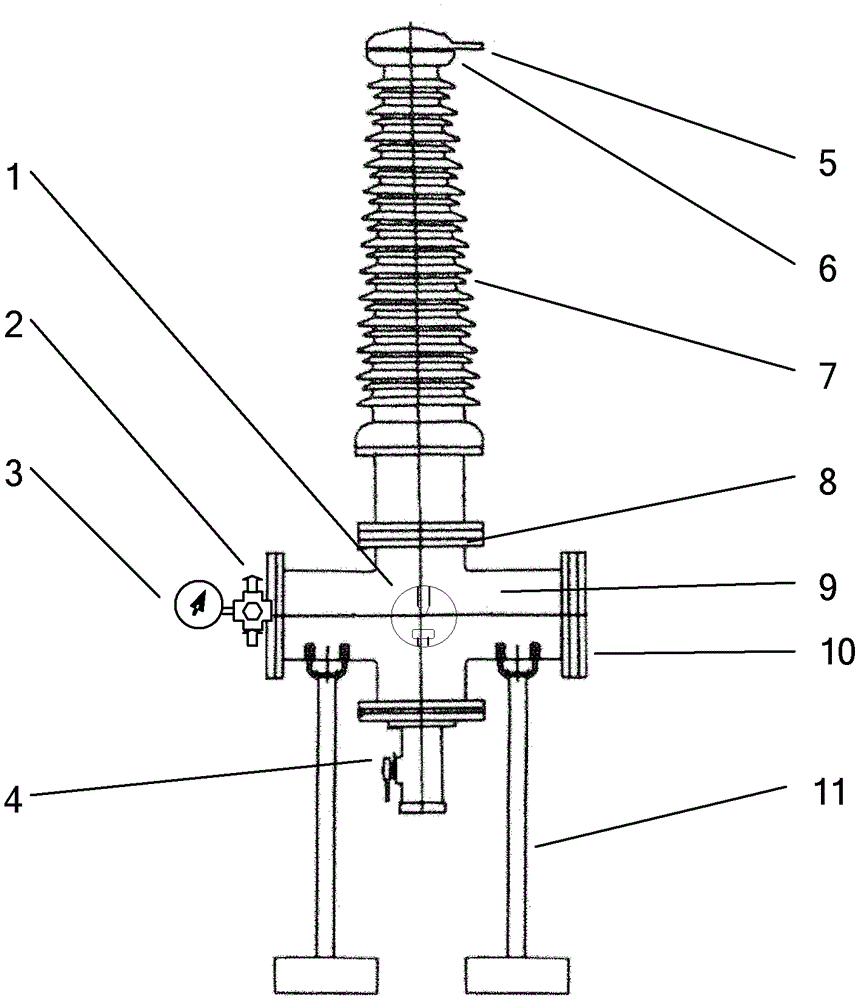

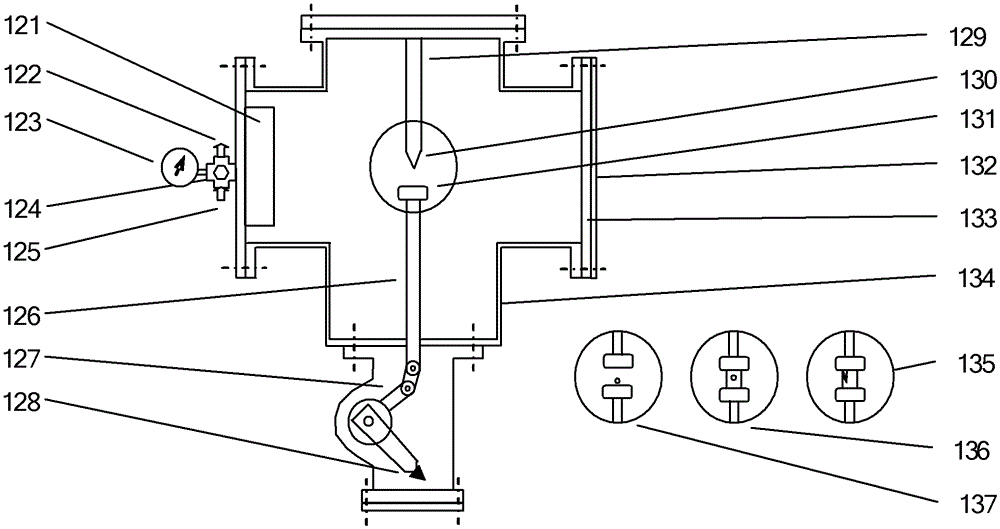

[0031] Please refer to figure 1 with figure 2 , figure 1 Shown is a schematic diagram of the structure of the metal-enclosed combined electric partial discharge simulation device of a preferred embodiment of the present invention, figure 2 Shown is a schematic structural diagram of a metal-enclosed gas chamber and an internal discharge electrode in a preferred embodiment of the present invention. The present invention proposes a partial discharge simulation device for a metal-enclosed combined electric appliance, which is mainly composed of six parts: a discharge electrode 1, a high-voltage bushing 7, a metal-enclosed gas chamber 9, a grounding device 4, a gas charging and discharging device 2, and an observation window 10; The discharge electrode 1 includes a high-voltage electrode 130, a gro...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap