Mounting and adjusting structure of building curtain wall vertical column and building body

A technology of building main body, installation and adjustment, which is applied in the direction of building components, building structures, buildings, etc., can solve the problems of limited operating space, limited construction site, variable operating positions, etc., and achieve overall cost saving, combination of flatness and beauty, and material selection convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

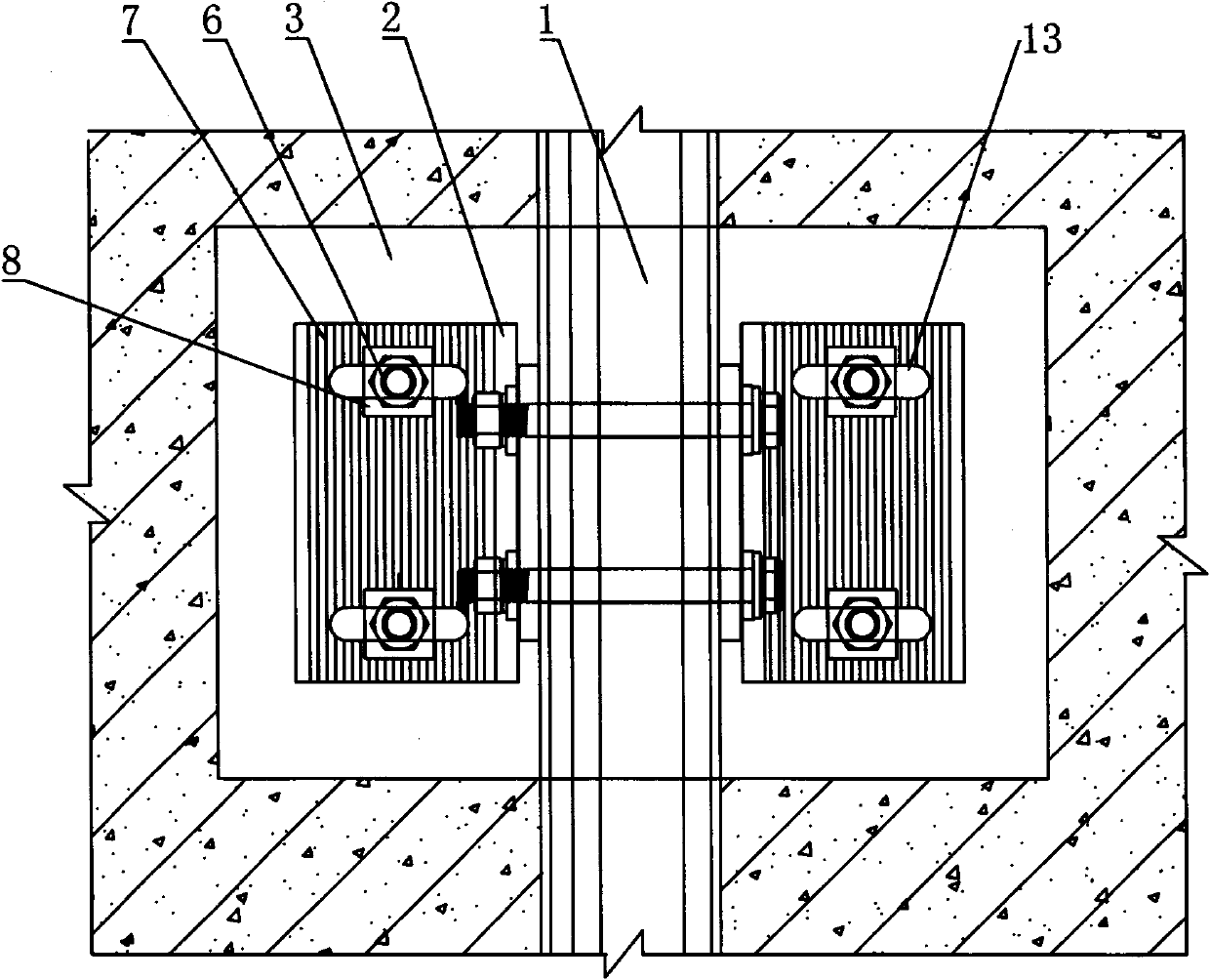

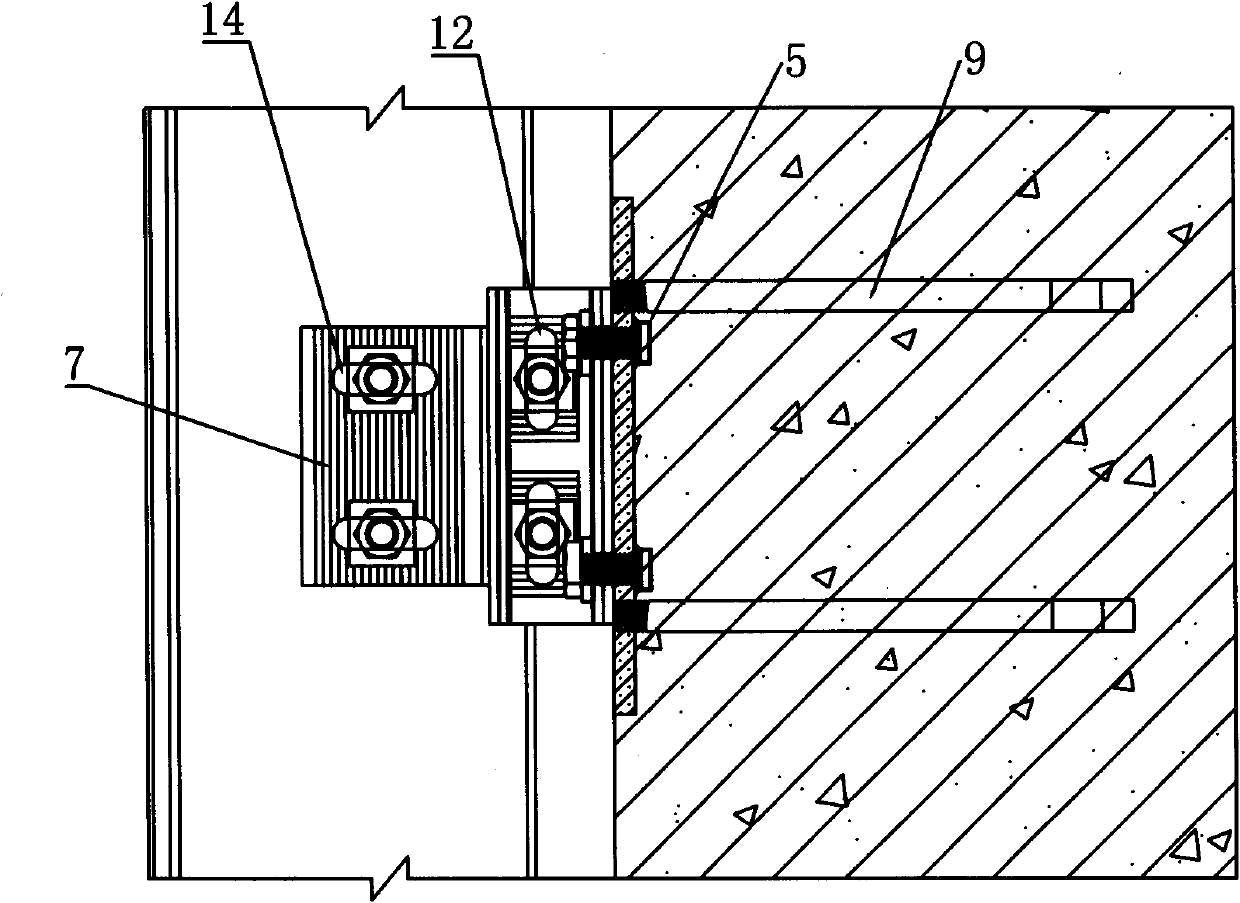

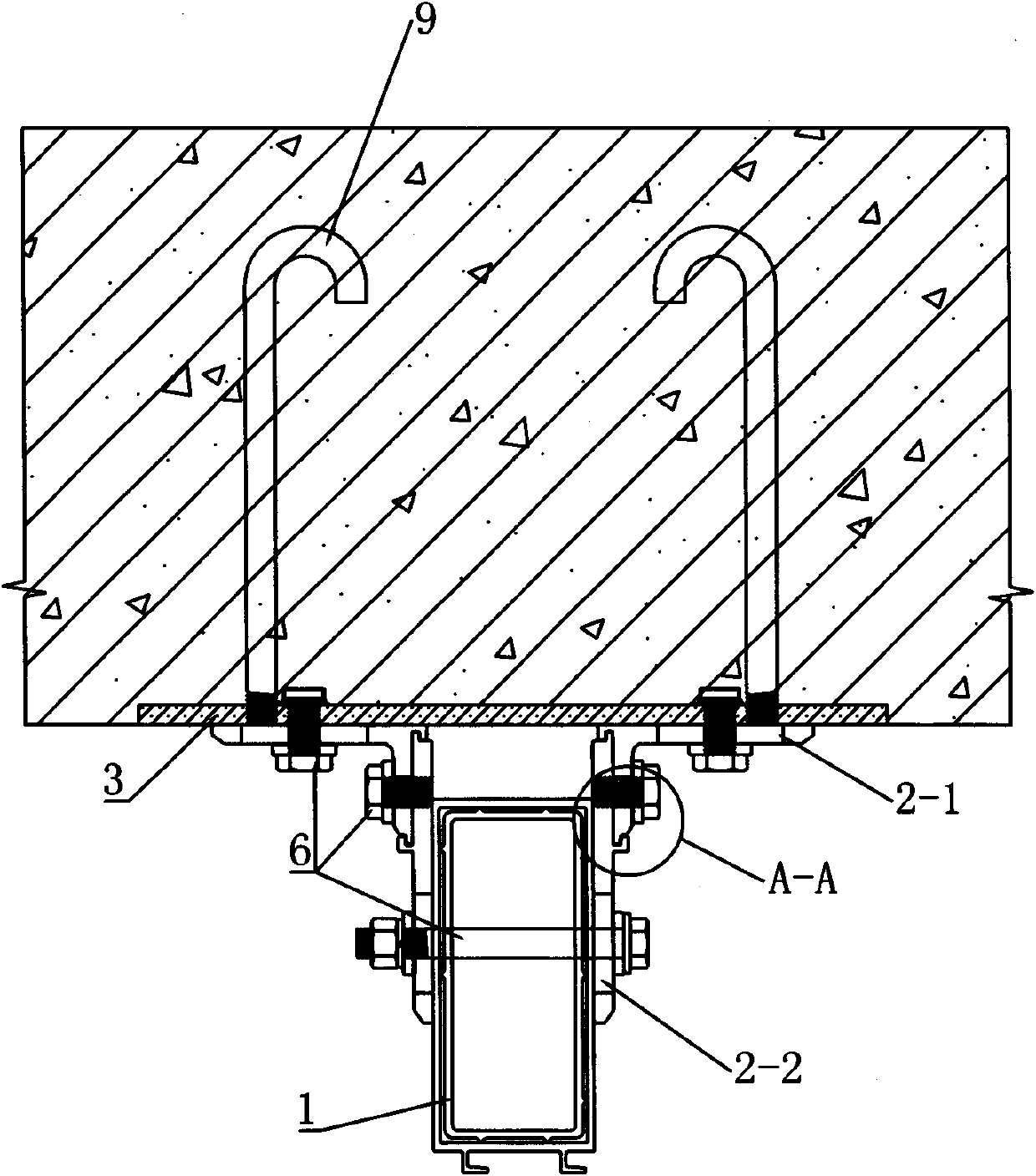

[0022] Such as Figure 1 to Figure 5 As shown, the installation and adjustment structure of a building curtain wall column and the main body of the building in the present invention includes a column 1 and a connecting corner piece 2 arranged on it, and a pre-embedded board 3 placed in the main body of the building. In this embodiment, the pre-embedded board Four screw holes 4 are tapped on the 3 in a four-corner distribution mode, and the embedded plate 3 is made of a steel plate, a plastic plate or an aluminum alloy profile plate; the connecting corner piece 2 is a corner piece or an aluminum alloy profile piece. The end face of the screw hole 4 is provided with a sealing cover or sealant 5 to prevent the entry of civil engineering materials. The screw hole 4 is correspondingly provided with a fastener 6 to fix the connecting corner piece 2 of the column 1 on the embedded plate 3. The fastener 6 Screws or bolts are generally used, and washers are sleeved on the screws or bol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com