Blue phase liquid crystal panel, blue phase liquid crystal device and manufacture method of blue phase liquid crystal panel

A blue-phase liquid crystal panel, technology of blue-phase liquid crystal, applied in the field of device and its manufacture, and blue-phase liquid crystal panel, can solve the problem of high driving voltage, reduce the driving voltage, solve the problem of high driving voltage, and promote the development of anisotropy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

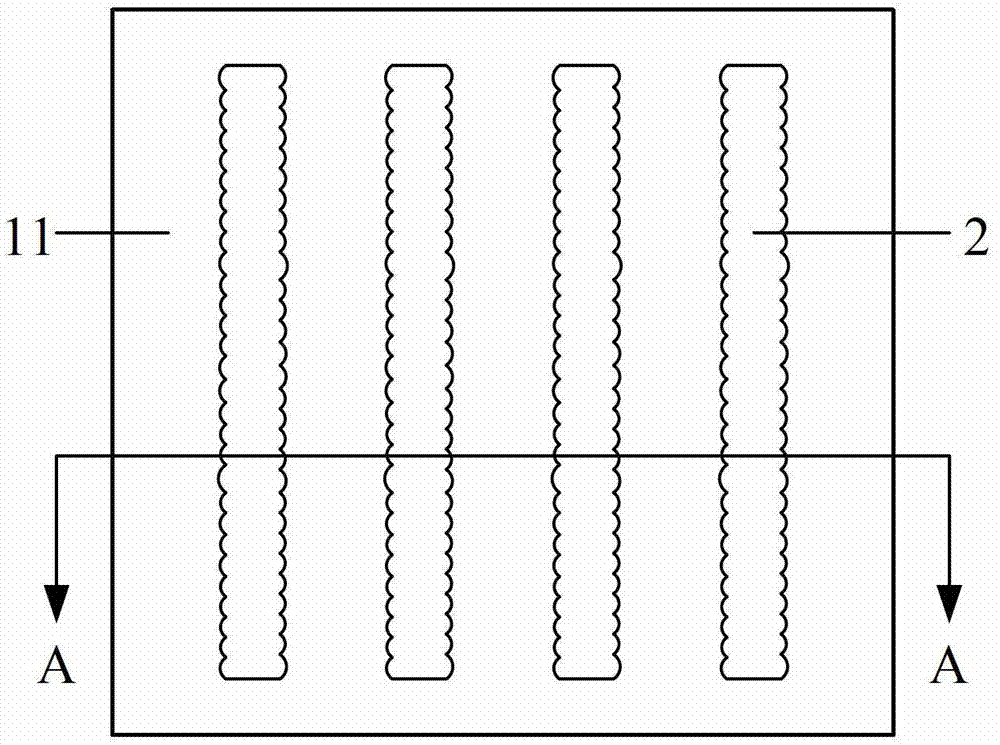

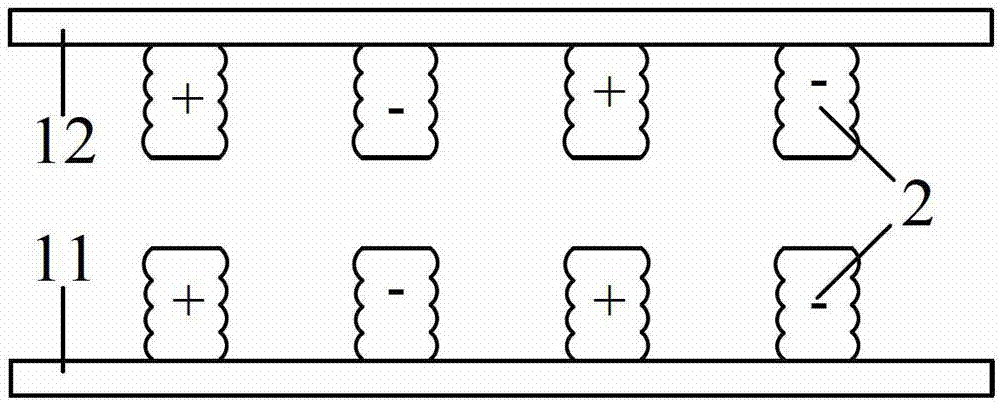

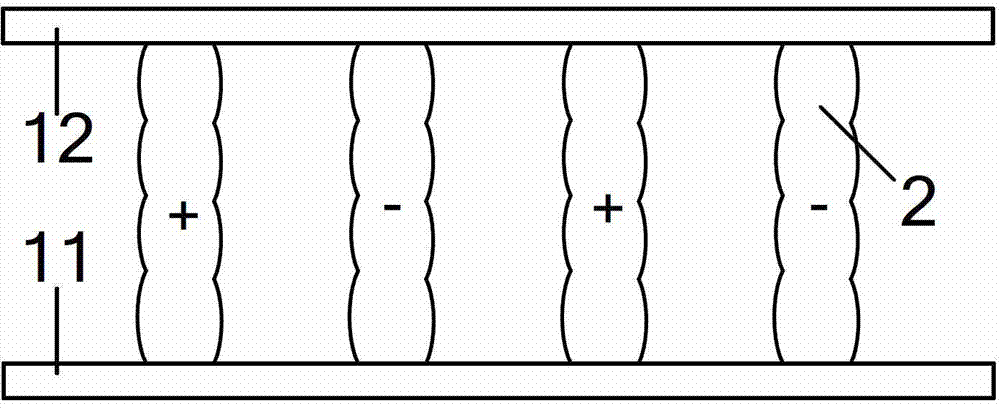

[0034] Such as figure 1 , figure 2 , image 3 As shown, the blue-phase liquid crystal panel provided by the embodiment of the present invention includes a lower substrate 11, an upper substrate 12, and a blue-phase liquid crystal located between the lower substrate 11 and the upper substrate 12 (the blue-phase liquid crystal is not shown in the figure), The lower substrate 11 and the upper substrate 12 are provided with driving electrodes for driving blue-phase liquid crystals, and the driving electrodes may also be provided only on the lower substrate 11 or only on the upper substrate 12 . The driving electrodes are wall-shaped electrodes 2 formed of hard conductive photoresist, and the surfaces of these wall-shaped electrodes 2 have wrinkle structures. Among the wall-shaped electrodes 2 , a horizontal electric field is formed between adjacent wall-shaped electrodes, and the blue phase liquid crystal is deflected under the drive of the horizontal electric field. The struc...

Embodiment 2

[0042] Such as figure 1 , figure 2 and image 3 As shown, the blue-phase liquid crystal panel provided by the embodiment of the present invention is basically the same as that of Embodiment 1, the difference is that the driving electrodes in this embodiment are wall-shaped electrodes 2 formed of flexible conductive photoresist, and these walls The surface of the shaped electrode 2 has a wrinkled structure.

[0043] Such as Figure 5 As shown, the specific manufacturing method of the driving electrode of the blue phase liquid crystal comprises the following steps:

[0044] S21 : coating a flexible conductive photoresist on the substrate 1 .

[0045] In the embodiment of the present invention, the substrate 1 may be a glass substrate, or an insulating layer, etc., which is not particularly limited here. The flexible conductive photoresist can specifically use a conductive photoresist containing a thermoelastic prepolymer, or a conductive photoresist of a flexible agent mon...

Embodiment 3

[0053] The blue-phase liquid crystal panel provided by the embodiment of the present invention is basically the same as the above-mentioned embodiment, the difference is that, as figure 1 , figure 2 and image 3 As shown, the driving electrodes are formed by a photoresist with a wrinkled wall structure, and the surface of the photoresist is covered with a conductive material, thus forming a wall electrode 2 with a conductive surface.

[0054] Such as Figure 6 As shown, the specific manufacturing method of the driving electrode of the blue phase liquid crystal comprises the following steps:

[0055] S31: Coating photoresist on the substrate.

[0056] In the embodiment of the present invention, it is sufficient to coat the substrate with a non-conductive ordinary photoresist, and the thickness of the photoresist can be arbitrarily selected from 0.1 to 100 microns according to specific conditions.

[0057] S32: performing a patterning process on the photoresist to form a wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com