Press fitting device of automobile connector

A technology of automotive connectors and pressing devices, which is applied in the direction of connection, circuit/collector parts, electrical components, etc., can solve the problems of low processing efficiency, low pressing precision, and difficult positioning, and achieve fast pressing speed, The effect of improving the processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

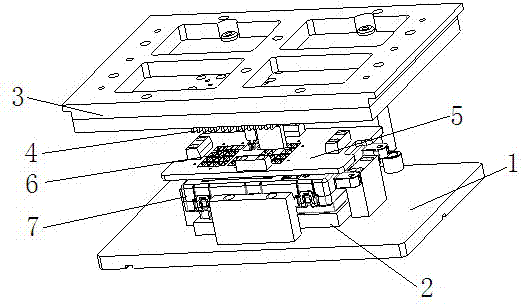

[0012] Such as figure 1 As shown, a pressing device for an automobile connector includes a base 1, a pressing plate 3 and several pressing heads 4, a boss 2 is provided on the base 1, and a square concave for placing an automobile connector 7 is arranged in the boss 2. A groove, a pressing plate 3 is arranged above the boss 2, and a plurality of pressing heads 4 for pressing electronic components on the automobile connector are arranged at the bottom of the pressing plate 3. A backing plate 5 is arranged between the boss 2 and the indenter 4, and a plurality of positioning holes 6 are provided on the backing plate 5 to limit the position of the electronic components, and each indenter 4 can extend into the corresponding positioning hole within 6.

[0013] To sum up, the automobile connector pressing device of the present invention is provided with a groove in the bos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com