Sheet metal stamping machine

A stamping machine and plate technology, applied in the field of plate stamping machines, can solve problems such as low processing efficiency, waste of wood, and inability to align wood plates, and achieve the effect of improving processing efficiency and speeding up the pressing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below by means of specific embodiments:

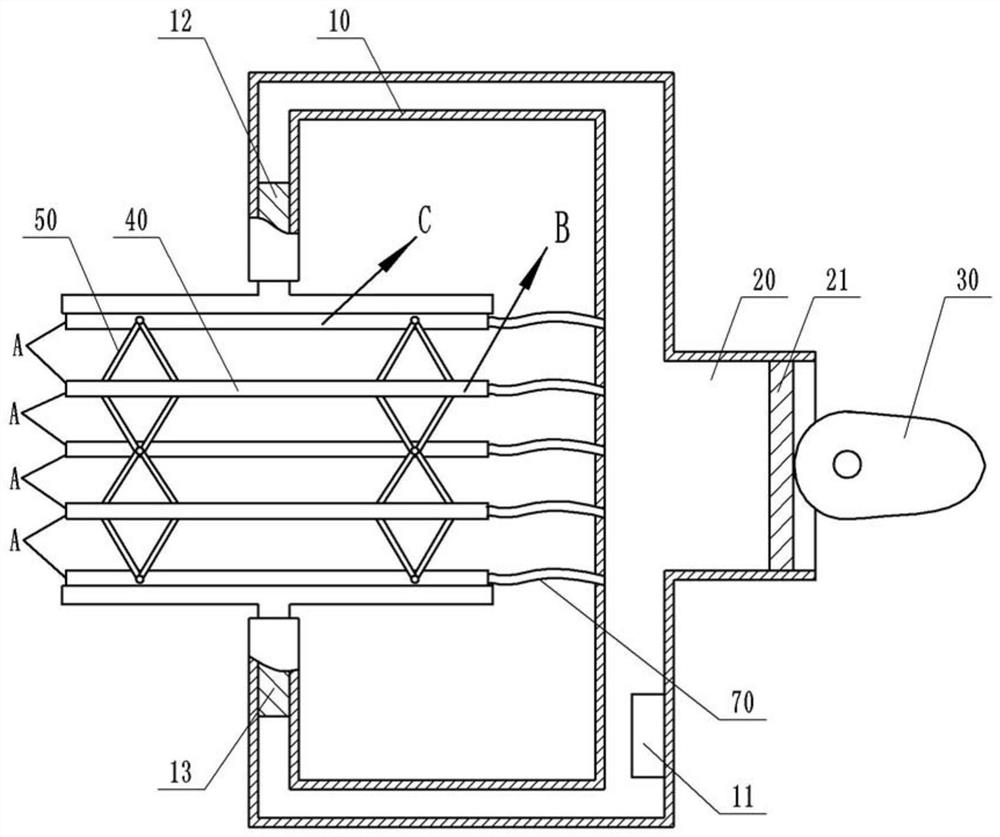

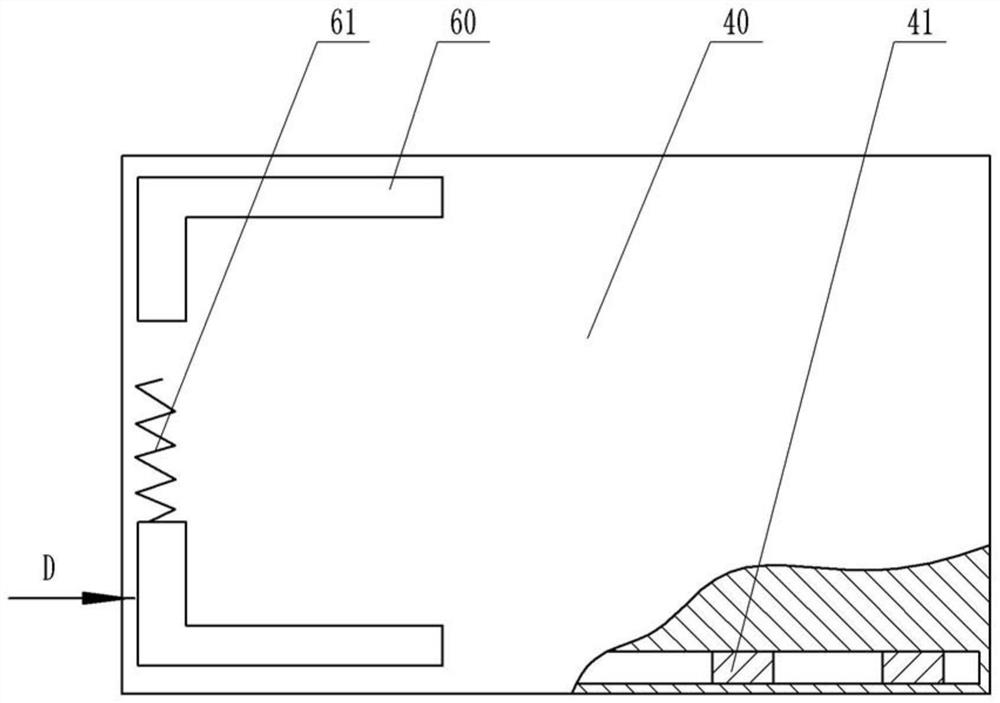

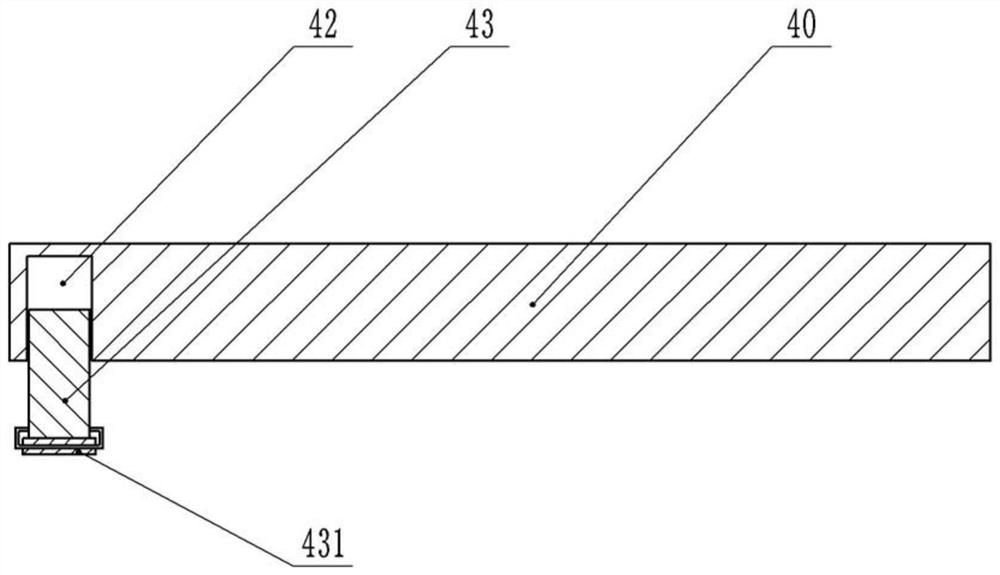

[0021] Instructions attached Figures 1 to 4 The reference signs in include: hydraulic column 10, heating device 11, first piston column 12, second piston column 13, piston cylinder 20, piston 21, cam 30, pressing plate 40, slider 41, groove 42, column Plug 43, roller 431, connecting rod 50, L-shaped clamping plate 60, spring 61, rigid bellows 70.

[0022] Such as figure 1 As shown, the plate stamping machine includes a pressing mechanism, a transmission mechanism and a power mechanism. The pressing mechanism includes a plurality of pressing plates 40 arranged horizontally from top to bottom, and any two adjacent pressing plates 40 form a pressing unit , figure 1 The one marked by A is a pressing unit. The pressing unit is provided with a force transmission structure. The force transmission structure includes two connecting rods 50 and two sliders 41 that are slidably...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com