Method and device for the manufacture of glazing comprising a decorative film and glazing comprising a decorative film

A manufacturing method and technology for glass windows, applied in crafts, decorative arts, window/door frames, etc. for producing decorative surface effects, can solve problems such as high financial expenses, and achieve reduced risk, low cost, accurate and cost-effective solutions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] The invention relates to the manufacture of glazing, in particular of vehicle glazing, in particular the invention relates to the manufacture of motor vehicle glazing.

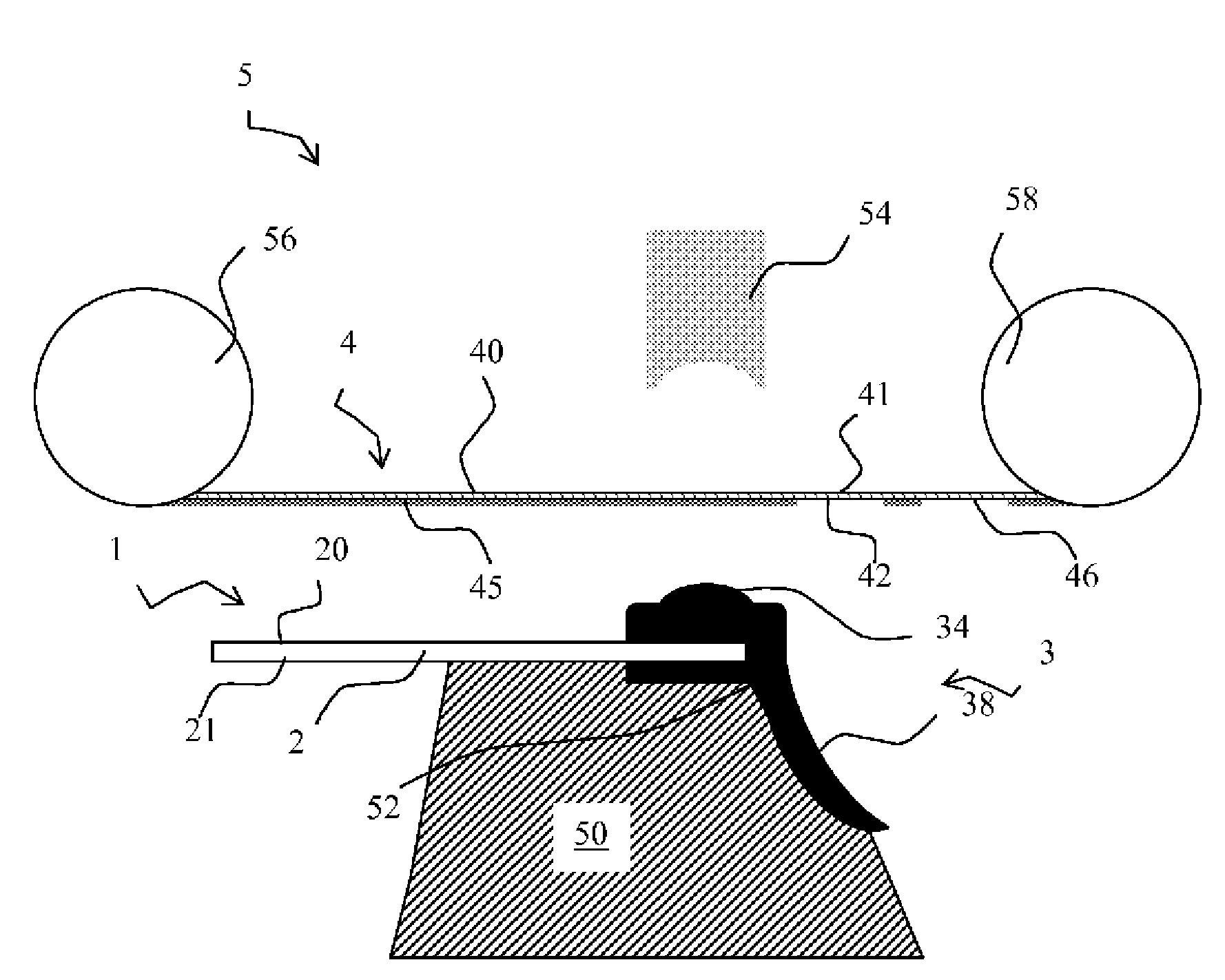

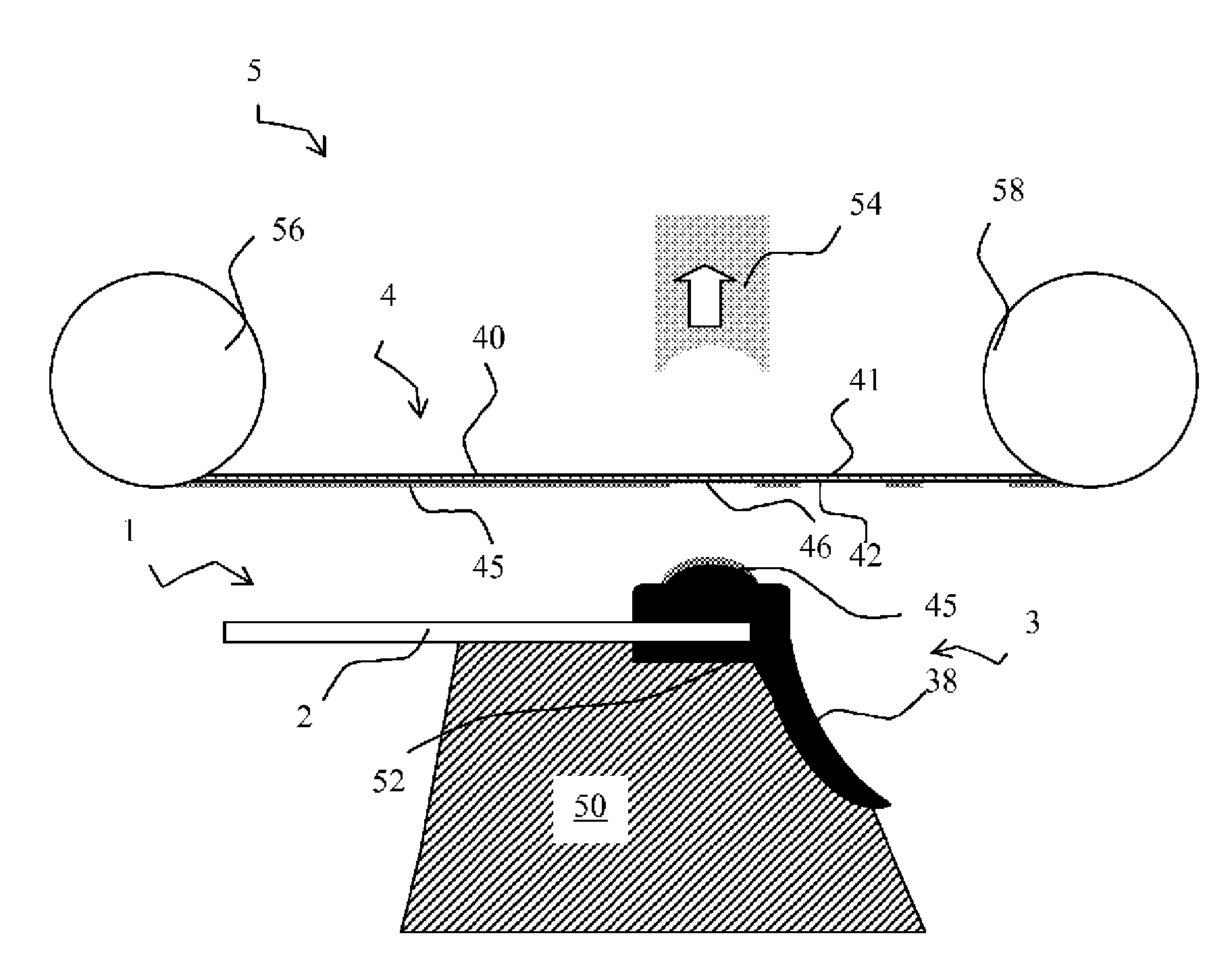

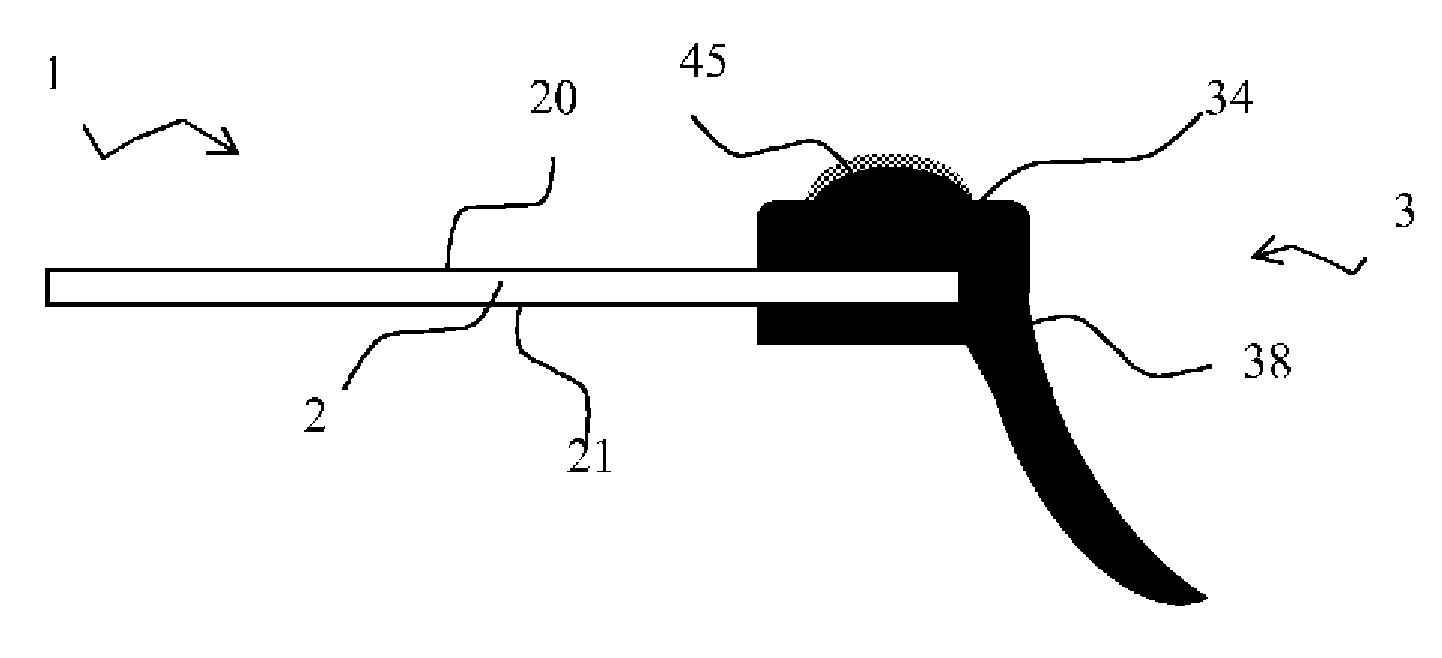

[0074] A glazing 1 according to the invention comprising a glazing element 2 which is hard and rigid and provided with a profiled strip 3 portion, said glazing 1 having at least one soft and / or hard portion, said soft portion belongs to the profiled strip 3 , while the hard part belongs to the glass element 2 or to the profiled strip 3 .

[0075] A glazing consisting at least of glazing elements and molding strips and possible accessories, especially for fixing the glazing, is used to close door and window openings and to separate the interior space from the exterior space. The glass element thus has an inner surface for facing the inner space and an outer surface for facing the outer space and a peripheral side.

[0076] The glazing element can be monolithic, i.e. consist of a single sheet of material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com